-

Products

-

Application

The crusher is now one of the indispensable equipment in various mines, coal mines and other industrial production. It is the pioneer to help other forming equipment to crush and grind the raw materials.

Among the crushers, there are roller crushers, rotor crushers and jaw crushers. Among them, the roller crusher is very common. However, compared with the traditional roller crusher, the high pressure roller mill has obvious advantages. Usually as the finishing equipment for crushing and grinding work.

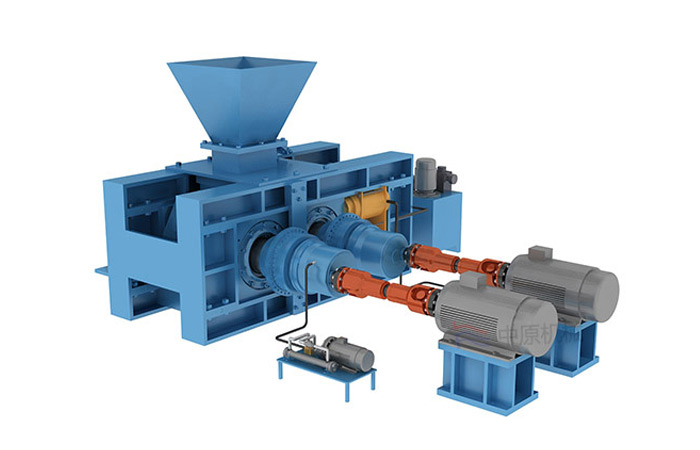

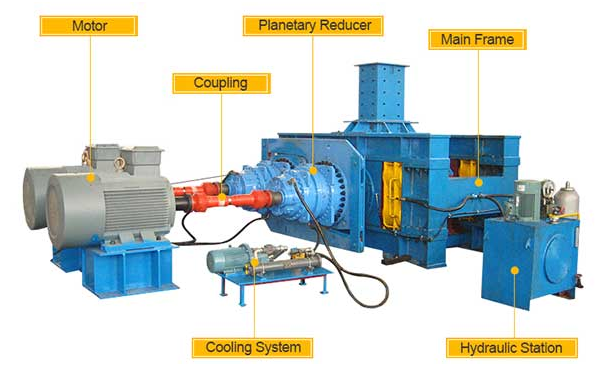

The high-pressure roller mill is a new type of crushing equipment with a high degree of automation. It contains more detection and early warning systems to effectively protect the equipment; bearings and other transmission components have the advantages of wear resistance and long service life due to their large specifications; There are few parts in contact with the material, and the amount of maintenance is small.

The high-pressure roller mill has a good selective crushing effect. The fine-grained materials produced by the crushing complete the initial monomer dissociation, and at the same time, cracks are generated inside the mineral particles, which can reduce the grinding work index during the grinding process, and then Reduce power consumption and increase production capacity.

The high-pressure roller mill can handle many types of materials, such as medium-crushed products, fine-grained products can be pre-grinded, and materials with high water content can also be processed.

The high-pressure roller mill can be used as fine crushing and ultra-fine crushing in actual concentrator applications. It can also use closed-circuit screening, side material circulation or open-circuit crushing. It can be synchronized with crushing operations or ore grinding operations.

The high-pressure roller mill is crushed by static pressure. The crushing process has no collision or impact, and has low noise; the equipment material, crushing and discharging are all carried out in a closed state, and the generated dust is small.

Because the high-pressure roller mill is very similar to the traditional roller mill in form, many people mistakenly believe that the high-pressure roller mill has the same shortcomings as the traditional roller mill. But in fact, there are two essential differences between the high-pressure roller mill and the traditional crushing technology.

The static pressure of the material layer of the high-pressure roller mill can make the material "smashed into pieces". The traditional machine is a crusher designed based on the principle of crushing to "divide the material into two." This quasi-static crushing method saves energy consumption by about 30%~50% compared with the impact crushing method.

Laminated crushing is the mutual crushing of materials. Compared with the traditional crushing and ball milling technology, the crushing efficiency of this principle is significantly improved, and the wear is also significantly reduced.

Official Agent of ZY MINING in Russia.

Please enter here.

Add: Luoxin Industrial Zone,Luoyang City,Henan Province P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com