-

Products

-

Application

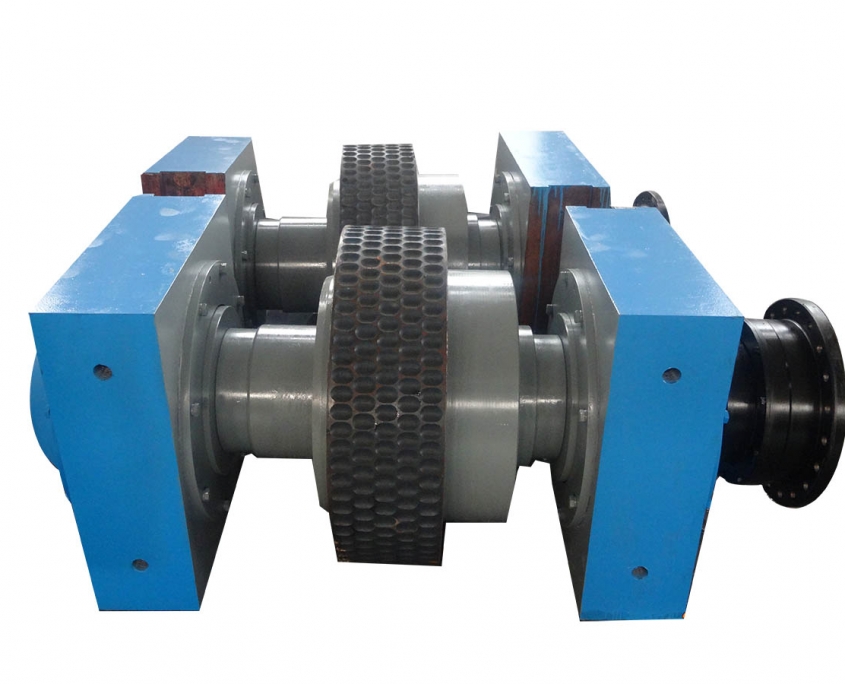

The roller skin of the ball press is the core component of the ball press. The quality of the ball skin of the ball press determines the service life of the ball press directly. The hardness of the roller skin of the ball press is the most important parameter to measure the quality of the roller skin of the ball machine. The hardness of the roller skin depends on the alloy steel number selected and the final heat treatment process level.

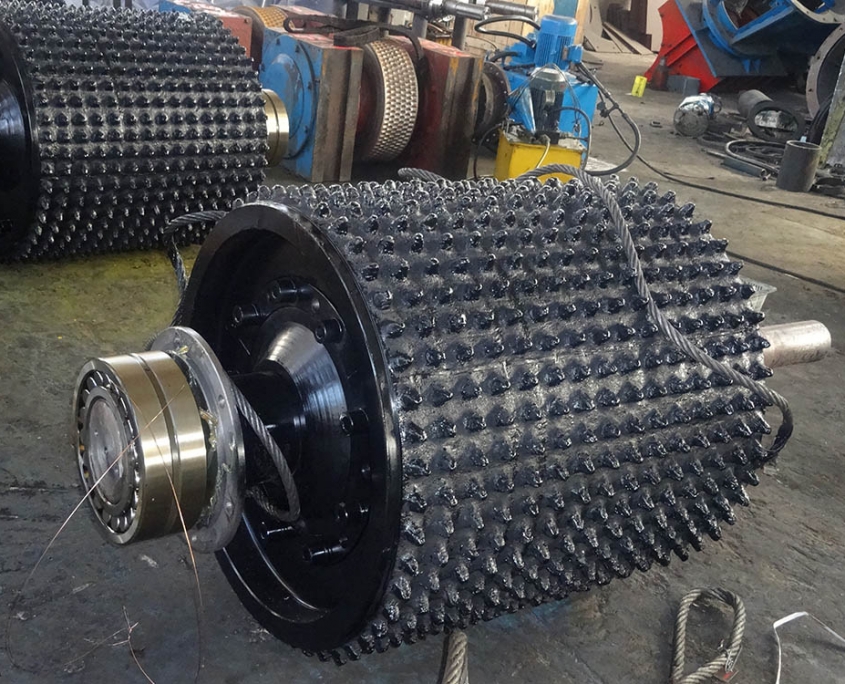

The roller skin of the ball pressing machine is made into blanks according to the drawings of the roller skin, and then turned to make it clear on all sides. The next step is to sculpt the ball and socket on the circumference of the roller skin. Of course, the size and shape of the ball and socket need to be determined jointly according to the diameter of the roller skin and the material pressed. The last process is heat treatment, which is also the most critical one. In the case of the same raw material of the roll, the hardness of the roll is determined by the heat treatment.

From the technical point of view, the roller skin can be divided into two types, casting and forging. The commonly used steel grade for casting roll skin is 65 manganese alloy, which has a relatively low cost, but the hardness of the roll skin is not too high, and it is not very wear-resistant. It is suitable for pressing delicate materials such as coal powder and clay. The commonly used steel number of forged roll skin is 92 Ming molybdenum, which has a high price and cost, but the hardness of the roll skin is relatively high, which can reach above HRC62, which is suitable for pressing rough materials such as iron powder and metal ore powder.

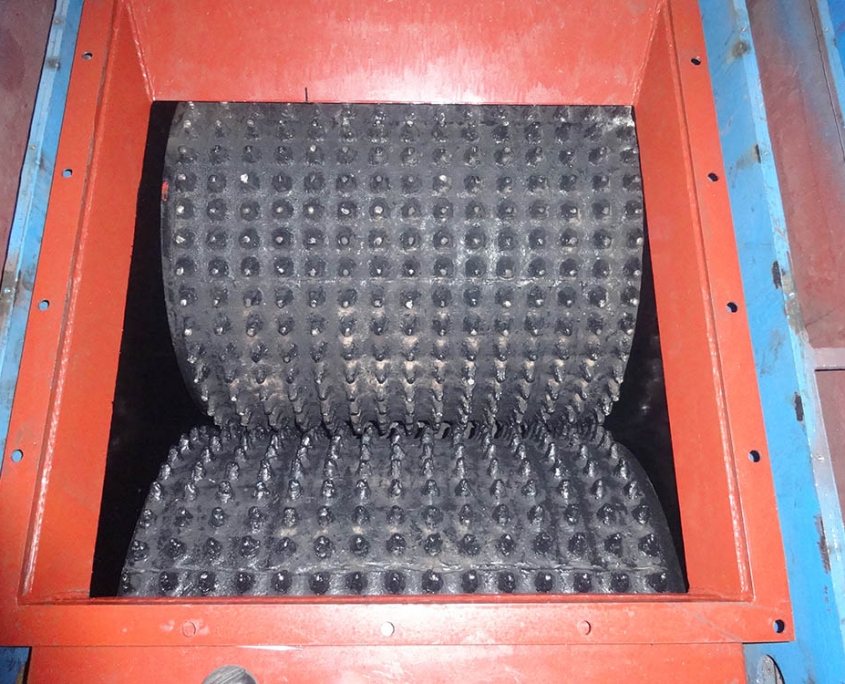

The shape of the material of the roller of the ball press machine is the significance of the purchase of the machine for the powder, and the roller skin will produce abraded parts in the production. For example, if the powder is doped with some high-hardness materials, it must be screened. If the roller skin is worn after pressing, it must be replaced.

The importance of the roller skin parts of the ball press is well known, and it is even more important. If problems occur in the production of the roller skin of the ball press, the results can be imagined. If the roller skin of the ball press takes a long time or is damaged, the customer must replace it in a timely manner to avoid that the products produced can not meet the predetermined conditions and cause waste of raw materials.

So from what aspects should the customer judge whether the roller skin is replaced?

(1) Use some professional testing instruments to carry out regular inspections, and the specific usage methods will have corresponding instructions.

(2) A comprehensive view based on personal experience.

(3) It is more direct to look at the effect of the ball.

The replacement of the roller skin of the ball press is mainly disassembly and installation, but in the replacement process, the corresponding removal and installation process must be mastered to achieve the safe and efficient replacement of the roller skin.

1. The power must be turned off, and the main switch can be turned on.

2. After the power is cut off, put a warning sign "under repair" in a conspicuous position.

3. First, perform pressure relief treatment on the lubricating pump, pull the switch for the supply belt of the mine belt, clean up the pumice on the belt head, and remove the four major parts, such as the guard of the feed port, the large pot, the cover plate, and the fixed cone dust cover. . During the hoisting process, the crane needs to be directed by a special person, and strictly observe the hoisting operation regulations.

4. If the old lining board cannot be removed, you can use gas welding to cut and clean the inner surface of the rack.

There are four installation methods, and everyone can compare their ball presses to install the appropriate method.

1. Bolt tightening method, that is, the roller sleeve and the hub are designed with bolt holes and tightened with refined high-strength bolts. This method is convenient for the on-site disassembly of the roller sleeve. Wet method, low-pressure ball press, kaolin ball Machine applications.

2. The cone sleeve assembly method, that is, the roll sleeve or the hub is designed with a taper, and it is tightened by the middle cone sleeve. This form is conducive to the disassembly of the roller sleeve and is used in the low and medium pressure ball press.

3. The tight fit hot-loading method, that is, the roller sleeve with ball socket is heated and installed on the wheel hub. This assembly form has high processing accuracy and strict processing temperature control. Special devices must be used when replacing, and it is generally used in high-pressure ball presses. Powerful ball press.

4. Key connection assembly method: The shaft and the sleeve have key grooves. The shaft and the sleeve are connected by keys. Because the shaft has key grooves and threads, the diameter of the main shaft of the ball press equipment is slightly larger than the shaft diameter of the keyless assembly. .

After all the operations are completed, the machine can be disconnected for trial operation. After the empty machine runs for a period of time, the materials can be added normally to start the operation. Remind everyone that the roll skin has been damaged for a long time or has to be replaced in a timely manner to avoid the production of products that do not meet the predetermined conditions, so as to cause waste of raw materials.

Official Agent of ZY MINING in Russia.

Please enter here.

Add: Luoxin Industrial Zone,Luoyang City,Henan Province P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com