-

Products

-

Application

The main mixing objects of horizontal strong continuous mixer are: the mixing of a variety of solid materials and powders, and the high-precision mixing of these materials after adding a binder. It is widely used in metallurgy, building materials, refractory materials, ceramics, glass, plastics, compound fertilizers and other solids. At the same time, the horizontal strong continuous mixer is also particularly suitable for mixing viscous materials. However, the purpose of high-precision mixing is inseparable from its structure. .

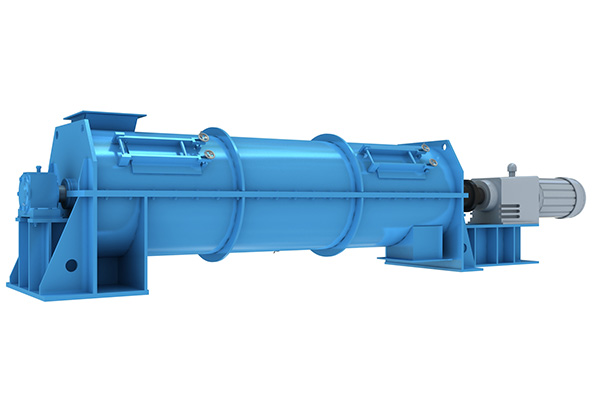

The horizontal strong continuous mixer consists of a frame, a barrel, a mixing tool, a rake tooth, a composite rubber lining, a transmission system and a control system. The transmission system is composed of a hydraulic coupling, a V-belt, a torque sensor, an explosion-proof motor, and a hydraulic Motor and other components.

The single-axis multi-cavity design is adopted, and the teeth are arranged in different geometric shapes. The materials are put into the front and rear movable curtains of the horizontal strong continuous mixer body to achieve cross and mixing between the materials. This horizontal strong continuous mixer is particularly suitable for mixing powder and powder, as well as mixing and mixing between powder and a small amount of liquid (binder), or mixing between materials with a large specific gravity.

The U-shaped long cylinder structure of the horizontal strong continuous mixer ensures that the mixture in the cylinder moves with less resistance. The positive and negative screws of the horizontal strong continuous mixer are installed on the same horizontal axis, resulting in low power and high efficiency. In a stirred environment, the horizontal strong continuous mixer usually consists of two or three layers. The outer spiral collects material from both sides to the center. The inner spiral transports the material from the center to the side, so that the material forms more eddy currents in the flow, thereby accelerating the mixing speed of the horizontal strong continuous mixer and improving the mixing uniformity.

When working, through the mixing tools arranged in the middle of the equipment, and 13 or 26 mixing rakes in different directions on the mixing tools, the materials entering the mixing equipment will be sprayed, sheared, scattered, and scattered strongly in the form of convection. Exchange, etc., so that the materials are fully blended in the barrel of the mixer and move to the discharge end of the mixing equipment. In this way of mixing, the materials to be mixed are not easy to agglomerate and agglomerate in the mixing equipment.

In the process of mechanical mixing and mixing of materials, there are mainly the following five methods:

(1) Shearing and mixing form shearing surfaces in the materials, so that the materials will be mixed.

(2) Convective mixing of many agglomerated material particles move from one part of the mixer to another for relative flow.

(3) Diffusion of the particles of the mixed mixture, moving around with a single particle as a unit, similar to the molecular diffusion process in gas and liquid. It is irregular movement, especially when the particulate material (dust) is vibrated or fluidized, the diffusion effect is extremely obvious.

(4) The impact mixing causes the individual material particles to disperse under the impact of the material and the wall shell.

(5) Deformation and crushing of particles of the crushed mixture.

Five mixing methods exist simultaneously in each mixing process, but the first three play a major role. Taking batch mixer as an example, the mixing process can be divided into three stages.

First, the particles in agglomerates from one part of the material in a layered form to penetrate and slip to another part, and convective mixing occurs.

Secondly, the particles of different ingredients gradually disperse across the newly formed interface and diffuse and mix.

Finally, under the action of its own weight and centrifugal force, particles of similar shape, size and density will gather in different parts of the mixer, which is called particle aggregation.

The first two effects are helpful for mixing, and the latter is a separation effect that hinders the uniform distribution of particles. These three stages happen at the same time in the mixer, but in different mixing time, the effect is different.

Official Agent of ZY MINING in Russia.

Please enter here.

Add: Luoxin Industrial Zone,Luoyang City,Henan Province P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com