-

Products

-

Application

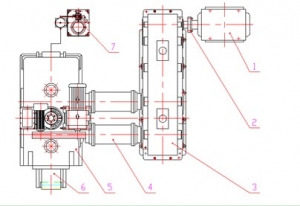

The briquetting machine can be divided into many categories according to the application industry, including direct reduced iron briquetting machine, briquetting machine used in the chemical industry, etc. In fact, the working principle of each briquetting machine is the same, we can through the GY520 to pressure the ball machine to do an analysis for everyone.

Principle of work: the main components of roller ball machine is a diameter equal to each other have a certain gap on roller.

Two on the roll at the same speed as the reverse rotation. Two on the roll surface arranged regularly in many shapes of ball socket of the same size. Two pairs of rollers are arranged horizontally, the powder and granular materials from two of the top roller continuously and evenly to join, rely mainly on small silo within the preloading spiral between forced feeding into the two roll. To roll into the material as before, free flow, from a certain point on the roll surface is on the roll bite. With the rotation of the rollers, materials occupy space decreases gradually,gradually compressed, reach the molding pressure maximum value, then the pressure decreases gradually.

Type ball pressed by the elastic recovery and have increased in size, bonded ball and ball and socket wall damage, coupled with its own weight and smooth fall off.

Official Agent of ZY MINING in Russia.

Please enter here.

Add: Luoxin Industrial Zone,Luoyang City,Henan Province P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com