-

Products

-

Application

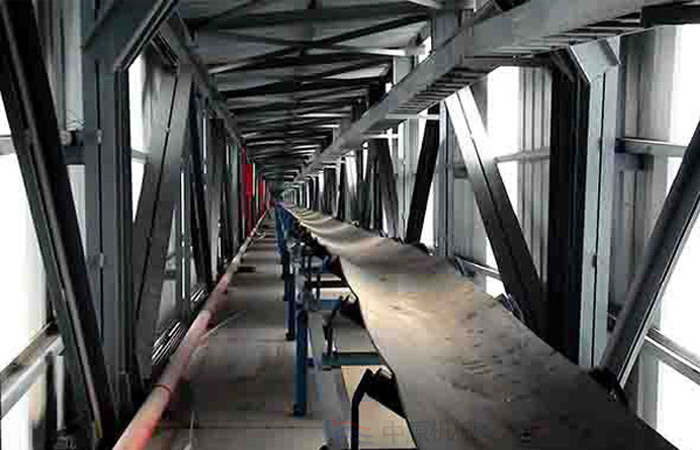

The idler is an important part of the belt conveyor. If there is a problem with the idler, it will definitely affect the life of the belt conveyor . Since the idler is so important, the conveyor manufacturer will share with you what are the types of belt conveyor idlers?

1. Groove upper idler

The standard groove angle of the grooved idler is 35°, so the 35° grooved idler and the 35° grooved forward-tilt idler are mostly used in a conveyor, and in the selection of these two types of idlers There are three forms, namely full forward tilt and partial forward tilt (one set of forward tilt rollers in every 5 sets of upper rollers) and no forward tilt rollers. At present, the first two types of idlers are relatively common. Of course, there are 45-degree grooved idlers and 45-degree grooved forward-tilt idlers.

2. Buffer roller

Common buffer idlers have 35-degree and 45-degree grooved idlers. Under normal circumstances, if you are using a cotton fabric core conveyor belt, you can only use a 35-degree grooved buffer idler. The 45-degree grooved buffer idler can be used in the section where the guide groove is not impacted by the material.

3. Transition roller

4. Return roller

The standard style of the return idler is still the parallel lower idler, and it is also the lower idler that is used more at present. In addition, the parallel lower idler has two forms: single-roller type and double-roller type. As for which one to use, the designer should choose according to the bearing capacity of the idler. And according to the research, it is found that making the lower idler into a two-roller V-shape has a certain effect on preventing the deviation of the lower branch of the conveyor belt, especially the V-shaped forward tilting lower idler has a more obvious anti-deviation effect.

5. Comb roller

Comb rollers are not used in many places, and most of them are used in conveyors specially designed for conveying viscous materials.

6. Spiral idler

The spiral idler is used to clean the material adhering to the bearing surface of the conveyor belt.

7. Self-aligning roller

The self-aligning idler is mainly used to automatically correct the excessive deviation of the conveyor belt during operation to ensure the normal operation of the conveyor. And the installation accuracy of the self-aligning idlers is high, especially for the conveyors that have been set up with forward-inclined idlers, the self-aligning idlers may not be set up. Generally, a conveyor with self-aligning idlers is required, and one set of every 10 sets of idlers is set. Align the rollers.

In summary, this is a detailed introduction to the types of belt conveyor idlers. If you have any questions in use, please feel free to contact us.

Official Agent of ZY MINING in Russia.

Please enter here.

Add: Luoxin Industrial Zone,Luoyang City,Henan Province P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com