-

Products

-

Application

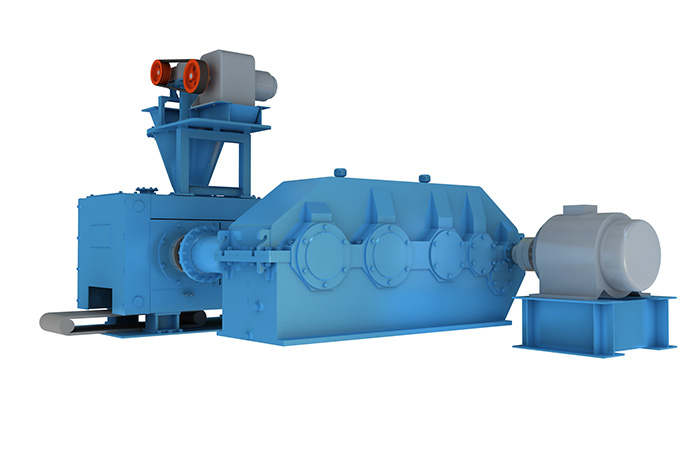

A briquetting press, also known as a briquette press or briquette machine, is a device used to compress materials into compact, solid briquettes. It is commonly used in industries that deal with the processing and disposal of various types of waste materials or biomass.

The process of briquetting involves transforming loose or powdered materials into denser briquettes by applying high pressure. The materials are typically in the form of biomass, such as sawdust, wood chips, agricultural residues, or industrial waste, including metal shavings, paper, and plastic.

Here's a general overview of how a briquetting press works:

Material Preparation: The raw materials are collected and prepared for the briquetting process. This may involve shredding or grinding the materials to achieve a consistent size and removing any impurities or contaminants.

Feeding the Material: The prepared material is then fed into the briquetting press. Depending on the type of briquetting press, the material may be loaded manually or through an automated feeding system.

Compression: Once inside the press, the material is compressed using a combination of high pressure and a specialized pressing mechanism. This pressure causes the particles to bind together, forming solid briquettes.

Binding Agent (Optional): In some cases, a binding agent or binder may be added to the material before or during the briquetting process. This can improve the briquette's structural integrity and provide better combustion characteristics.

Briquette Formation: The compressed material is shaped into briquettes of the desired size and shape using specially designed molds or dies. The briquettes can be cylindrical, rectangular, or other customized shapes depending on the application.

Cooling and Solidifying: After the briquettes are formed, they may undergo a cooling process to allow them to solidify and retain their shape. This can be achieved through natural air cooling or using cooling systems integrated into the briquetting press.

Briquette Discharge: Once the briquettes have cooled and solidified, they are discharged from the press. They can be collected in storage bins or conveyed to packaging systems for further handling or distribution.

Briquetting presses offer several benefits, including reducing the volume of waste materials, improving handling and storage efficiency, and creating a renewable energy source. The resulting briquettes can be used as fuel in industrial boilers, power plants, or domestic heating, depending on the composition and calorific value of the materials used.

It's worth noting that there are different types and models of briquetting presses available, ranging from small-scale manual presses to large-scale automated machines, each suited to specific production requirements and material characteristics.

Official Agent of ZY MINING in Russia.

Please enter here.

Add: Luoxin Industrial Zone,Luoyang City,Henan Province P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com