-

Produkte

-

Toepassing

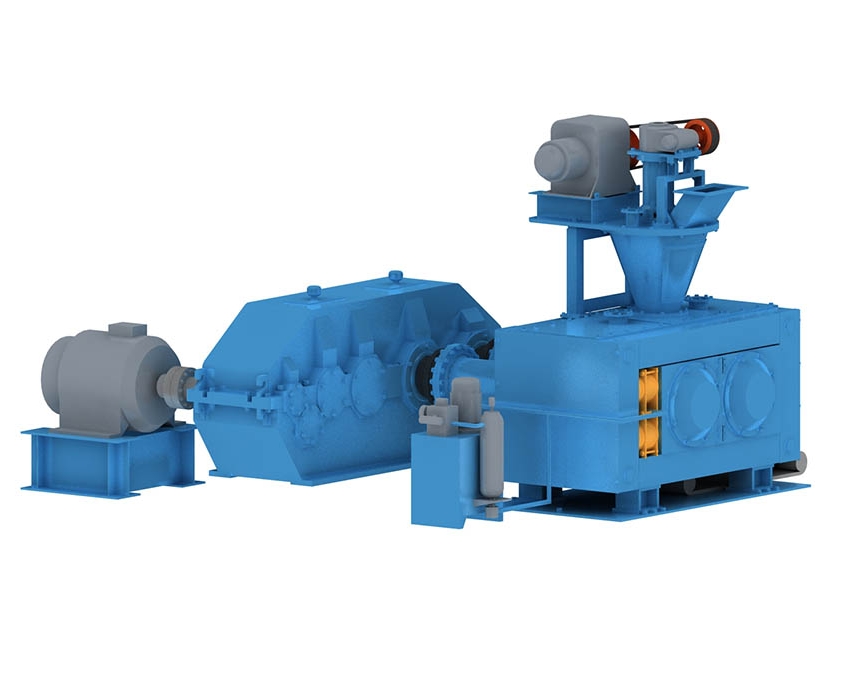

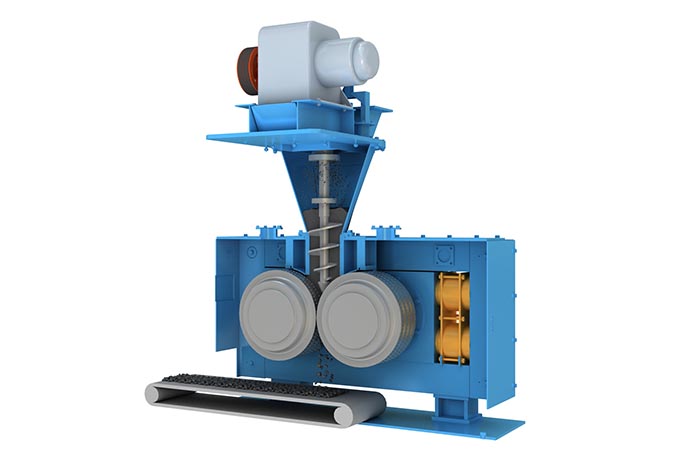

Umshini we-briquetting usesimweni sokusebenza okuqhubekayo isikhathi eside, kuhambisana nokugcinwa okungalungile nezinye izici zangaphakathi nezangaphandle, okwenza izingxenye eziningi zihluleke ngaphambi kwesikhathi. Impilo yesevisi yomshini we-briquetting ikakhulukazi incike kwikhwalithi yezingxenye zayo zokugqoka, ikakhulukazi i-roller yokucindezela. I-pair of pressure rollers izothuthukisa kakhulu impilo yesevisi ye-ball press, kodwa ngisho nama-roller angcono kakhulu azochithwa. Umkhawulo wesikhathi kanye nezinga, khona-ke kufanele kube yini indinganiso yokukhipha izingxenye ezigqoke zomshini wokubopha?

1. Ukuhlanekezela kwerimu yerimu yegiya akufanele kube kukhulu kuno-7.5mm.

2. Ukugqokwa kwe-pinion surface akufanele kube kukhulu kuno-30% wobukhulu bezinyo. Ukuguga kwendawo enkulu yezinyo kufanele kube kukhulu kunama-25% wobukhulu bezinyo. Ingasetshenziswa ohlangothini olungemuva, futhi kufanele ichithwe uma iphansi ibe yi-1/2.

3. Ama-grooves, amamaki angaphandle kwe-shaft engenalutho noma ukuguga kwendawo endaweni eyindilinga engaphakathi kuzobangela ukuthi i-shaft engenalutho iguge futhi iqhekeke, futhi kufanele ishintshwe.

Lezi zimo ezingenhla zivamile kithi. Uma umshini we-briquetting wonakalisiwe, ungasetshenziswa ngokujwayelekile. Akufanele kuphela igcinwe ngokucophelela, kodwa futhi isetshenziswe ngomgomo. Ngokuvamile imishini iphukile, sizocela umkhandi ukuthi ayilungise. Eqinisweni, singakwazi nokulungisa ezinye izinto ngokwethu, bese sizisebenzisa.

Ekusetshenzisweni kwethu kwansuku zonke komshini wokucindezela ibhola lempushana eyomile, ngokuvamile kunezigigaba ezingathandeki. Kwesinye isikhathi abasebenzisi abanalo isipiliyoni kule ndawo futhi bakunake ngokwanele lokhu, kodwa ukuthuthukiswa okungahleliwe kwezinye izigigaba kuzodala imiphumela emibi kakhulu.

Izenzakalo ezivamile:

1. Ukubonakala kwe-shaft engenalutho kubangelwa ama-grooves, amamaki noma ukuguga okuyingxenye endaweni eyindilinga yangaphakathi ukuze kubangele ukuguqulwa kwe-shaft engenalutho kanye nemifantu kanye nezinye izimo kufanele kushintshwe.

2. Ukuhlanekezela kwerimu yerimu yegiya akufanele kube kukhulu kuno-7.5mm.

3. Ukugqokwa kwe-pinion surface akufanele kube kukhulu kune-30% yobukhulu bezinyo. Ukuguga kwendawo enkulu yezinyo kufanele kube kukhulu kunama-25% wobukhulu bezinyo. Ingasetshenziswa ohlangothini olungemuva, futhi kufanele ichithwe uma iphansi ibe yi-1/2.

4. Ukugqoka kwesihlahla esithwalayo kukhulu kune-1/3 yobukhulu bayo.

Okungenhla yizinga elijwayelekile lezingxenye ezigugile nezilahliwe zomshini wokubopha osetshenziswayo. Uma kukhona noma yiziphi izinkinga ezingenhla, izingxenye zomshini we-briquetting kufanele zishintshwe ngesikhathi sangempela. Izesekeli zomshini we-briquetting ezilahliwe, ngesikhathi esifanayo, kufanele zilungiswe njalo ukuze zenze umshini we-briquetting uphile isikhathi eside.

Add: I-Luoxin Industrial Zone, Idolobha laseLuoyang, Isifundazwe saseHenan P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com

Amptelike agent van ZY MINING in Rusland.

Skryf asseblief hier in.

Add: I-Luoxin Industrial Zone, Idolobha laseLuoyang, Isifundazwe saseHenan P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com