-

Produkte

-

Toepassing

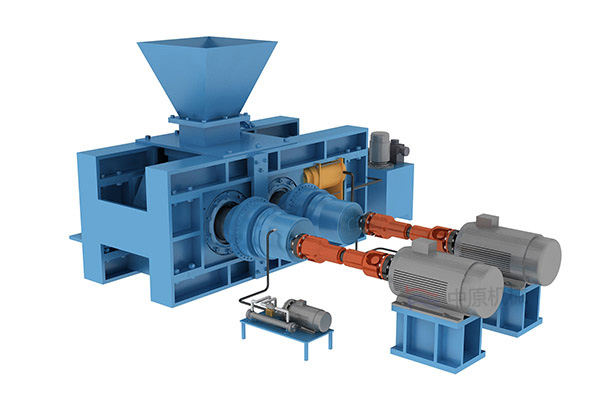

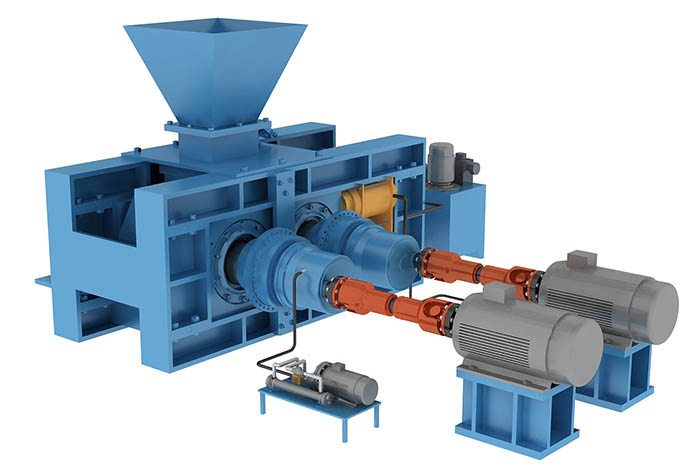

I-high-pressure roller mill ithandwa kakhulu ezinkampanini ezinkulu zezimayini zanamuhla. Isizathu asikwazi ukuhlukaniswa nokusebenza kahle kwayo nokonga amandla. Kwabanye ozakwethu abancane abangakathengi, isigayo se-high-pressure roller siseyinto engavamile yokuchotshozwa, ngakho-ke Uma uthenga, akucaci ukuthi hlobo luni lwemishini yamandla oyifunayo, ngakho-ke umkhiqizi we-high-pressure roller mill ulapha. ukukusiza ukuthi ukhethe isigayo se-roller esinengcindezi ephezulu, futhi uthemba ukuthi wonke umuntu angakhetha okokusebenza okufanele.

I-high-pressure roller mill inomphumela omuhle wokuchoboza kanye nekhono lokucubungula eliqinile, elingathuthukisa kakhulu umthamo wokucubungula webhola lebhola. Inemiphumela ephezulu yokonga amandla kanye nezinzuzo ezinkulu zezomnotho. Ilungele ukuchotshozwa nokugaya izinhlobonhlobo zezinsimbi zensimbi, ama-non-metal ores, ama-pellets, i-steel slag, njll. Ukusebenza kungaletha ukuthuthukiswa okuningi ezinhlelweni ezihlukahlukene zokukhiqiza:

1. Ngemuva kokuthi uhlelo lokuchoboza lwengezwe kumshini we-high-pressure roller, usayizi wezinhlayiyana zokukhishwa kwe-cone ochotshoziwe kahle ungaphinda kabili, ongakhuphula umthamo wokukhiqiza futhi unciphise ukusetshenziswa kwamandla kokuchotshozwa;

2. Ngemuva kokuthi uhlelo lokugaya lwengezwe kumshini wokucindezela ophezulu, ubukhulu bezinhlayiyana zebhola lebhola buyancipha kakhulu. Ngenkathi ukwandisa amandla nokunciphisa ukusetshenziswa, amaminerali aphukile aqhekeke kancane kancane eduze kwe-crystal lattice direction, ngaleyo ndlela athuthukise ukusebenza kahle kokugaya futhi azuze Ukukhethwa kwamaminerali Kamuva;

3. Inqubo yokukhiqiza yesigayo se-high-pressure roller yenza izinto ezibonakalayo zifinyelele "ukuchotshozwa okwengeziwe nokugaya kancane", okungafinyelela usayizi wezinhlayiyana ze-ultra-fine ezingaphansi kuka-3 mm.

Ukukhethwa komshini wokugaywa we-high-pressure roller kunqunywa ngokuyinhloko umthamo wokucubungula iyunithi yezinto zokusebenza, amandla emoto, igebe le-roll kanye nempilo ye-roll surface. Le datha ihlukile kumishini yokucaciswa okuhlukile:

Ngokusho kosayizi wezinhlayiyana ezihlukene zokuphakela, ubulukhuni bensimbi, ukuminyana kwe-ore kanye nezidingo zosayizi womkhiqizo, umthamo wokucubungula iyunithi womshini wokugaya ofanayo ophezulu we-high-pressure nawo uhlukile. Uma ufuna ukukhetha imishini enamandla okucubungula aphezulu, udinga ukuba nezidingo zezinto zokwakha kanye nemikhiqizo. Nginokuqonda okujulile ukuthi ngaphansi kwezimo ezijwayelekile, ukuminyana kwekhekhe cishe kungama-85% obuningi be-ore. Izinto ezithinta umthamo wokucubungula iyunithi yesigayo se-high-pressure roller yizi:

(1) Ububanzi be-roller ye-pressure ye-high pressure roller mill;

(2) Ububanzi be-pressure roller ye-high pressure roller mill;

(3) Isivinini somugqa we-roller yokucindezela ye-high-pressure roller mill, njll.

Amandla emoto we-high-pressure roller mill awahambisani nokucaciswa kwawo namamodeli. Ngokuvamile kubalwa futhi kunqunywe ukusetshenziswa kwamandla kweyunithi ehloliwe. Amandla enjini eyodwa kufanele abe ngu-0.69 high-pressure roller mill unit processing umthamo ophindwe ngokusetshenziswa kwamandla eyunithi. Abanye abalingani abancane bakhetha ukukhetha injini enkulu, ebangela ukumosheka kwamandla.

Igebe le-roll ne-roll surface nakho kungenye yezinto ekukhethweni kwezigayo ze-high-pressure roller. Igebe elizwakalayo lokugoqa kufanele libe phakathi kuka-2.8% no-3.0% wobubanzi bendawo yeroli, futhi usayizi wokuphakelayo akufanele weqe ububanzi begebe le-roll; Ngaphansi kwezimo ezijwayelekile, ububanzi bezinto eziseceleni buphinda kabili igebe le-roll elinengqondo, futhi uma lincane izinga lokuhlala lezinto eziseceleni, kuba ngcono umphumela wokugoqa. Ngakho-ke, ngokusemandleni akho, khetha idivaysi enendawo ebanzi ye-roll ngenkathi uqinisekisa ukusebenza kwemishini.

I-roller surface material iyisici esibalulekile ekunqumeni impilo ye-roller surface. Ngakho-ke, lapho ukhetha isigayo se-roller high-pressure, kufanele uqonde ukuthi yini impahla esetshenziswe endaweni ye-roller. Ngesikhathi esifanayo, kunconywa ukukhetha isivinini esilinganayo esilingana nobubanzi bendawo ye-roller. Ingaphezulu liqinisekisa impilo ye-roller surface.

Ngokusekelwe ezicini zokukhetha ezingenhla, kungabonakala ukuthi usayizi omkhulu we-high-pressure roller mill, kungcono. Ngenxa yosayizi ohlukile wokuphakelayo, akuyona into enhle ukukhetha usayizi omkhulu womshini wokugaywa we-high-pressure roller. Ngakho-ke, kutuswa ukuba uqinisekise ukuthi Lapho okuphumayo kwaneliseka, khetha imodeli enobubanzi obungaphezulu bomugqa omncane ngangokunokwenzeka. Izinzuzo zokwenza kanjalo yilezi:

(1) I-diameter ye-roll incane futhi ububanzi be-roll bukhulu, okunganciphisa umthelela womphumela womphumela wokuchoboza;

(2) Nciphisa isisindo sawo wonke umshini, wehlise umthamo wesikhungo, futhi unciphise ukutshalwa kwezimali kwezokwakha;

(3) Yehlisa inani lempahla yezingxenye ezisele;

(4) Izingxenye eziyisipele ezivamile zingashintshaniswa futhi zisetshenziswe ukuze kuqinisekiswe ngempumelelo ukuzinza kohlelo.

1. Ukucindezela kwesistimu kufanele kunqunywe ngokuvumelana nemvelo yamaminerali agaywe yi-high-pressure roller mill kanye nosayizi wezinhlayiyana ezifanelekayo okufanele zichotshozwe. Lapho uhlangabezana nezidingo zosayizi wezinhlayiyana ezichotshozwayo zokukhiqiza, ingcindezi ye-roller surface encane iba ngcono. Uma ingcindezi ebusweni be-roller inkulu, ukusetshenziswa kwamandla kuzoba kukhulu, ukugqoka kwe-roller surface kuzothuthukiswa, futhi izindleko zezomnotho zizokhula. Ngesikhathi esifanayo, umphumela wokuchoboza awukhuli ngokuhambisana nokwanda kwengcindezi ye-roller surface. Lapho izinto zichotshozwa ngezinga elithile, ingcindezi ye-roller surface iyanda, futhi umphumela wokuchoboza ucishe ushintshe kancane.

2. Njengamanje, kunezinhlobo ezintathu eziyinhloko ze-roll surface emakethe: i-surfacing roll surface, i-alloy roll surface kanye ne-stud roll surface. Ingakhethwa ngokuya ngezakhiwo zezinto ezibonakalayo. Ngaphezu kwekhwalithi nesivinini somugqa, wonke umuntu kufanele anake usayizi wezinhlayiyana zokuphakelayo lapho esisebenzisa. Uma usayizi wesiphakeli uqine kakhulu futhi ungagugi, uzogqoka kalula indawo eqengqelekayo. Ngesikhathi esifanayo, qaphela ukuvimbela ukungena kwezinto zensimbi, futhi ngokuqondile Umonakalo endaweni yomqulu.

3. Umswakama wezinto ezibonakalayo uzothinta ukusungulwa kwegumbi lokucindezela le-high-pressure roller mill. Uma umswakama wezinto ezibonakalayo mkhulu, kunzima ukwenza umcamelo wezinto ezibonakalayo, futhi i-roller surface matrix izoguga ngokushesha ngaphandle kwe-cushion yezinto ezibonakalayo. Kodwa ngesikhathi esifanayo, impahla ayikwazi ukungabi namanzi ngokuphelele, ikakhulukazi uma usayizi wezinhlayiya zokugaya umncane (ngaphansi kuka-1 mm), izinto ezomisiwe zijwayele ukudlidliza okufana ne-pulse, okunomthelela omkhulu kuwo wonke. high-pressure roller mill. Ngaphansi kwezimo ezijwayelekile, umswakama wempahla kufanele ulawulwe phakathi kuka-1.5% no-8%.

Okungenhla yikho konke okuqukethwe kweziphakamiso zokukhetha isigayo esinengcindezi ephezulu, okuyizindlela esizifingqe ngamanye amadokhumenti nemiphumela yokuhlolwa. Ngethemba ukuthi kungaba usizo kuwo wonke umuntu.

Add: I-Luoxin Industrial Zone, Idolobha laseLuoyang, Isifundazwe saseHenan P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com

Amptelike agent van ZY MINING in Rusland.

Skryf asseblief hier in.

Add: I-Luoxin Industrial Zone, Idolobha laseLuoyang, Isifundazwe saseHenan P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com