-

Produkte

-

Toepassing

Ikhanda lesando le-crusher liyingxenye ebalulekile yokuqinisekisa ukukhiqizwa okuvamile kwezinto ze-ore. Akuthinti kuphela ukukhishwa kwesihlabathi nama-gravel aggregates, kodwa futhi kuthinta ikhwalithi yemikhiqizo eqediwe. Abasebenzisi abaningi bakhathazeke kakhulu ngokuguga okukhulu kwekhanda lesando. Ngakho kanjani ukubhekana nakho? Ukuphendula le nkinga, umenzi we-crusher usinike isingeniso esiningiliziwe.

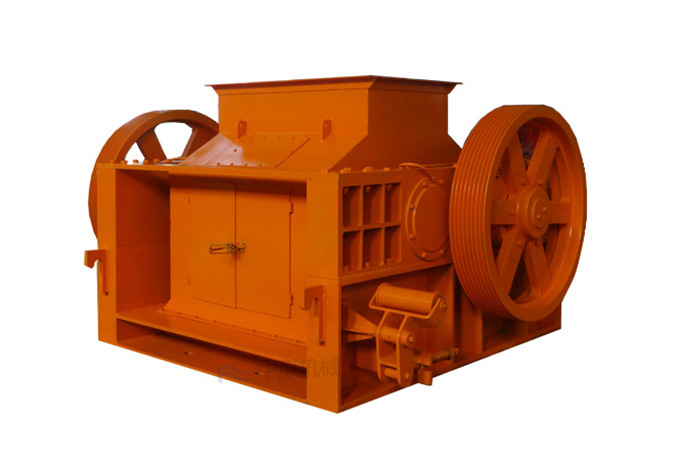

Kunezinhlobo eziningi kakhulu zama-crusher emakethe, okuhlanganisa ama-crusher anezando nama-crusher ngaphandle kwezando. Abanye abantu bathi njengoba ikhanda lesando livame ukugqokwa, kungcono ukukhetha i-crusher ngaphandle kwekhanda lesando. Eqinisweni, nakuba ama-crushers esando enenkinga yokuguga, amanye ama-crusher nawo anezingxenye ezigqokile, kodwa awawona amakhanda esando.

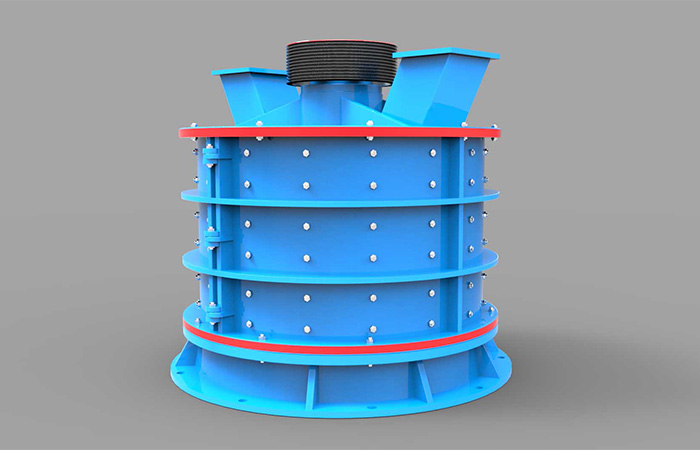

Ama-crushers avamile anezando emakethe ahlanganisa: izingqimba zomthelela, izingqimba zesando, izingqimba ezinhle, izingqimba eziqondile ezihlanganisiwe, njll. Lolu hlobo lwe-crusher elinesando ngokuvamile luyisigaxa somthelela. I-aggregate ekhiqizwayo inosayizi ongcono wezinhlayiyana futhi izophulwa eduze kwezikhala zensimbi. Kukhona imifantu embalwa ezinhlayiyeni. Umkhiqizo oqediwe uvame ukuba yi-cubic futhi unezinga eliphezulu lokuhlukaniswa. Ngakho-ke, abantu abaningi bazokhetha lolu hlobo lwe-crusher enekhanda lesando.

Ukuze uxazulule inkinga yokugqoka okungathí sina kwekhanda lesando le-crusher, kuyadingeka ukuthola imbangela yokugqoka okungathí sina kwekhanda lesando le-crusher bese ubeka umuthi ofanele. Izizathu eziyinhloko zokugqokwa okungathi sína kwekhanda lesando le-crusher yizinto zekhanda lesando, ikhwalithi yokukhiqiza kanye nomklamo wesakhiwo, umklamo wezobuchwepheshe we-crusher, isimo sokuphakelayo kanye nokuvunyelwa kwengxenye ngayinye yesakhiwo.

Isizathu 1. Impahla yekhanda lesando

Ukuqina nokuqina kwekhanda lesando kungenye yezizathu ezithinta ukugqoka kwekhanda lesando. Ngokuvamile, ukuqina okukhulu, kukhulu ukumelana nokugqoka kwekhanda lesando, kodwa njengoba ukuqina kukhula, ukuqina komthelela wekhanda lesando kuzokwehla. Ngakho-ke, isihluthulelo sokuthuthukisa ukumelana nokugqoka kwekhanda lesando ukuthola impahla enobulukhuni nokuqina okuhle.

Indlela yokwelapha: khetha ikhanda lesando lezinto eziqinile ezingagugi, njengensimbi ephezulu ye-manganese, insimbi ephezulu ye-chromium cast, insimbi ephansi ye-carbon alloy, njll.

Isizathu 2. Ikhwalithi yokukhiqiza yekhanda lesando

Inqubo yokukhiqiza yekhanda lesando iphinde inqume isici esiyinhloko sokumelana nokugqoka kwayo. Ngokusobala, uma ubuso noma ingaphakathi lekhanda lesando lingalungile ngesikhathi senqubo yokukhiqiza, njenge-shrinkage cavity, i-crack, i-transgranular nezinye izimo, hhayi kuphela ikhanda lesando elizoba lula ukugqoka, kodwa ngisho nekhanda lesando lizophuka.

Indlela yokwelapha: sebenzisa ubuchwepheshe bokukhiqiza ikhanda lesando elivuthiwe, yenza ukusakaza okunengqondo kanye nenqubo yokwelapha ukushisa. Isibonelo, lapho kukhiqizwa izando zensimbi eziphonswe nge-chromium ephezulu, sebenzisa ukusakaza okuqondile nokusetshenziswa okunengqondo kwensimbi ebandayo yangaphandle, futhi ulawule ngokuqinile izinga lokushisa ngesikhathi esifanayo, ukuze izando ezikhiqiziwe zibe nokulandelana okuhle kokuqina kanye nezimo zokudla, kanye nesakhiwo sangaphakathi. iminyene, nezinhlamvu ezimahhadla ziba buthaka.

Isizathu 3. Ukwakheka kwekhanda lesando

Isakhiwo nokuma kwekhanda lesando nakho kuthinta ukugqoka. Ukusebenza kokwelashwa kokushisa kanye nesakhiwo sangaphakathi samakhanda esando anezakhiwo ezahlukene kanye nokubunjwa kuhluke kakhulu, okubuye kuthinte ukumelana nokugqoka. Ikhanda lesando elinobukhulu obukhethekile nobukhulu bunomthelela omkhulu. Ngaphezu kwalokho, ukuqina kwekhanda lesando, kunzima ukuqinisa futhi kubi nakakhulu ukumelana nokugqoka.

Indlela yokucubungula: thuthukisa ukwakheka kwekhanda lesando.

Isizathu 4. Imingcele yezobuchwepheshe ye-crusher

Imingcele yezobuchwepheshe ethinta ukumelana nokugqoka kwekhanda lesando le-crusher ihlanganisa amandla nesivinini se-rotor. Lawa mapharamitha amabili abonisa isivinini somugqa namandla omthelela wekhanda lesando, futhi ahlobene namandla okukhiqiza we-crusher kanye nezinga lokuqina komthelela wekhanda lesando. Ukuqina komthelela Uma iziqu zizinhle, impilo yesevisi izonwetshwa. Uma ijubane le-rotor liphansi kakhulu, amandla okukhiqiza azoba aphansi, okuholela ekuqineni komthelela omubi wekhanda lesando nokumelana nokugqoka okubi; Kuzodala ukugqoka okuqinile ekhanda lesando kanye ne-liner, engalungile empilweni yekhanda lesando, futhi kuzokwandisa ukusetshenziswa kwamandla.

Indlela yokwelapha: thuthukisa imingcele yezobuchwepheshe, lawula amandla nesivinini se-rotor, hhayi phezulu kakhulu noma phansi kakhulu.

Isizathu 5. Igebe phakathi kwezingxenye esakhiweni se-crusher

Igebe elithinta ukugqokwa kwekhanda lesando le-crusher lihlanganisa igebe phakathi komzimba we-rotor, i-liner ye-crusher, nekhanda lesando. Ezimweni ezimbi kakhulu, kungase futhi kubangele ukuvinjelwa.

Indlela yokwelapha: lungisa ukucaciswa kwe-rotor, ikhanda lesando nezinye izingxenye ukuze wenze kube phakathi kwebanga elifanele.

Isizathu 6. Isimo sokudla kwe-crusher

Kunezimo ezimbili zokudla eziyinhloko ezithinta impilo yekhanda lesando, enye yizinto ezibonakalayo, kanti enye iyindlela yokudla.

Izinto ezibonakalayo zihlanganisa usayizi wezinhlayiya, ubulukhuni, okuqukethwe komswakama, njll. Ubukhulu bezinhlayiyana zezinto akumele zibe mncane kakhulu, futhi ubukhulu bomfutho wokushayisana buhlobene ngokuqondile nezinga lomsebenzi wokuqina nokugqoka ukumelana kwekhanda lesando; uma ubulukhuni bezinto ezibonakalayo bukhulu kakhulu, ijubane lokugqoka lekhanda lesando le-crusher lizosheshisa; uma okuqukethwe kwamanzi kuphezulu kakhulu, okubalulekile kuzobophezela kalula kuma-agglomerates, okuholela entweni eqoqiwe, ebhebhethekisa ukugqokwa kwekhanda lesando.

Izindlela zokuphakela ezihlukene zizodala ukwehla okuhlukile kusuka kokubalulekile kuya kurotha, okuzothinta umfutho wokushayisana lapho isando sishaya into.

Indlela yokwelapha: qinisekisa ukuthi ubukhulu bezinhlayiyana zezinto ezibonakalayo abuncane kakhulu, ubulukhuni abukhulu kakhulu, futhi okuqukethwe kwamanzi akuphakeme kakhulu; indlela yokudla igcinwa izinzile futhi ilinganayo.

Indlela elula iwukuqala ngendaba. Izinto ezisetshenziswa kakhulu zekhanda lesando le-crusher yinsimbi ephezulu ye-manganese, insimbi ephezulu ye-chromium cast, insimbi ephansi ye-carbon alloy nokunye. Ungakhetha ngokwezidingo zakho.

Insimbi ye-Gaomeng inokuqina okuhle, futhi isici sayo esiyinhloko ukuthi ngaphansi kwesenzo somthelela omkhulu noma ukucindezeleka kokuxhumana, ungqimba olungaphezulu luzokhiqiza ngokushesha ukuqina komsebenzi, futhi inkomba yokuqina komsebenzi icishe ibe izikhathi ezi-5 kuya kweziyi-7 kunezinye izinto. Ayinayo nje ukumelana nokugqoka okuphezulu, kodwa futhi inenani eliphansi. Kodwa uma amandla omthelela enganele, ukumelana nokugqokwa kwensimbi ye-Gaomeng akukwazi ukusetshenziswa ngokugcwele.

I-chromium cast iron ephezulu iyinto ekwazi ukumelana nokugqokwa enokumelana okuhle nokugqokwa, kodwa ukuqina kwayo kuphansi futhi ijwayele ukuphuka. Kodwa-ke, ekuphenduleni isidingo semakethe, abantu baye bakhiqiza amakhanda esando ayinhlanganisela, lapho insimbi ephezulu ye-chromium ishunyekwa ekhanda lensimbi ye-manganese ephezulu noma amakhanda ensimbi ye-low-alloy steel, noma ingxenye esebenzayo yekhanda lesando lenziwa. yensimbi ephezulu ye-chromium, futhi isibambo sesando senziwe ngensimbi ye-carbon. Insimbi, okuyinhlanganisela yalokhu okubili futhi yingakho negama layo, yenza ikhanda libe nobulukhuni obuphezulu futhi isibambo sesando sibe nokuqina okuphezulu, okunikeza ukudlala okugcwele ezinzuzweni ezihambisanayo zezinto ezimbili kanye nokunqoba ububi bento eyodwa.

Insimbi ye-low-carbon alloy ngokuyinhloko iyisakhiwo sensimbi ye-alloy equkethe izakhi ezihlukahlukene ezifana ne-lattice ne-molybdenum. Inobunzima obuphezulu kanye nokuqina okuhle. Isakhiwo sayo se-matrix sihlanganisa i-martensite, i-bainite noma i-bainite+martensite isakhiwo esiyinhlanganisela. Ngaphansi kwezimo ezifanayo zokusebenza, impilo yayo yesevisi okungenani iphindwe kabili kuneyekhanda lesando lensimbi ye-manganese ephezulu.

Ukufingqa, sihlele izimbangela nezindlela zokwelashwa zokugqoka kwe-crusher okunzima, kanye neziphakamiso zokukhetha ikhanda elihle lesando. Eqinisweni, ukugqokwa kwekhanda lesando le-crusher akunakugwenywa, kodwa esingakwenza ukunciphisa ijubane layo lokugqoka ngangokunokwenzeka futhi sandise impilo yayo yesevisi. Ngaphezu kwempahla yekhanda lesando, kufanele futhi ukhethe ngokuya ngezakhiwo zezinto onazo. Ngaphezu kwalokho, kufanele futhi unake indlela yokusebenza ngesikhathi senqubo yokukhiqiza, ukuze ukugqokwa kwekhanda lesando le-crusher kuzokwehla ngokwemvelo.

Amptelike agent van ZY MINING in Rusland.

Skryf asseblief hier in.

Add: I-Luoxin Industrial Zone, Idolobha laseLuoyang, Isifundazwe saseHenan P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com