-

Produkte

-

Toepassing

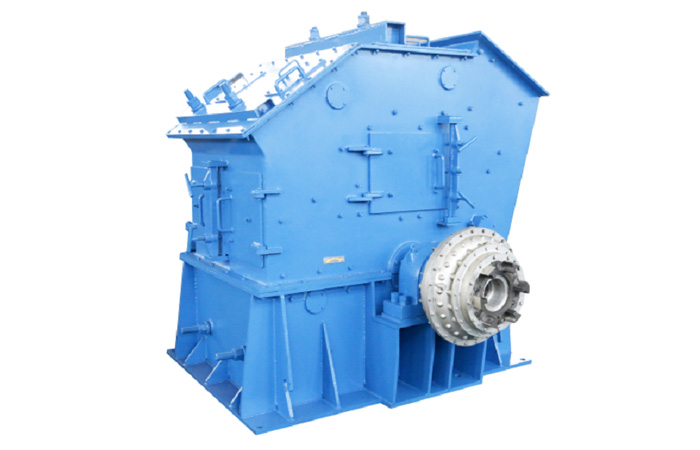

I-Impact crusher ingumshini wokuchoboza osebenzisa amandla anomthelela ukuchoboza izinto. Ingakwazi ukuphatha izinto ezinobude obuhlangothini obuyi-100-500 mm noma ngaphansi, ngamandla okucindezela afika ku-350 MPa, ngesilinganiso esikhulu sokuchoboza, futhi izinto ezichotshoziwe ziyizinhlayiya ze-cubic. Isetshenziswa kakhulu ezintweni zokwakha, ukuchotshozwa kwe-ore, izitimela, imigwaqo emikhulu, amandla, ezokuthutha, amandla, usimende, izimayini, amakhemikhali nezinye izimboni zezinto ezichotshozwayo eziphakathi nendawo, ubukhulu bokukhishwa bungashintshwa, futhi ukucaciswa kokuchoboza kuyahlukahluka.

Uma noma yimuphi umshini usetshenziswa isikhathi eside noma usetshenziswa ngendlela engafanele, uzodala isimo sokuthi ungasetshenziswa ngokujwayelekile. Ngakho-ke yimaphi amaphutha nezisombululo ezivamile uma usebenzisa isishicileli somthelela? Abakhiqizi be-crusher bakuthatha ukuze wabelane ngamaphutha abo ajwayelekile nezisombululo ngokuningiliziwe:

Hlola ukuthi izinto eziphambi kwesiphakeli ziwela yini emgodini ochotshozwayo ngenxa yokudlidliza kokuvalwa, okubangela ukuthi okokusebenza kunamathele ku-rotor. Kuyadingeka ukuhlanza izinto ezisegumbini lokuchoboza bese uqala umshini futhi ukuxazulula inkinga.

Kufanele kubhekwe ukuthi ukugcotshwa kwe-bearing kuhle yini. Ngaphansi kwezimo ezijwayelekile, amafutha okugcoba kufanele agcwaliswe ngo-50% wevolumu yesihlalo sokuthwala; kwesinye isikhathi, uwoyela wokugcoba uwohloka futhi u-viscous, futhi ukuthwala kudinga ukuhlanzwa futhi kufakwe amafutha amasha okugcoba. Uwoyela omningi noma omncane kakhulu ku-athire uzobangela ukushisa ukushisa. Lapho ufaka i-refueling, hlola izinga likawoyela. Uma i-bearing yonakele, buyisela i-bearing ngesikhathi. Uma ikhava engenhla iqine kakhulu, kuhle ukulungisa ukuqina kwebhawodi.

Uma kukhona ukudlidliza okungavamile, opharetha kufanele ayeke ngokushesha, sidinga ukuhlola izimo ezilandelayo.

(1) Hlola ukuthi akukho yini ukungcola kwensimbi noma izingxenye eziphukile ngaphakathi, bese uhlanza imbobo yokuchoboza;

(2) Hlola ukuqiniswa kwepuleti le-lining langaphakathi kanye negebe phakathi kwe-blow bar ne-lining plate. Uma igebe lincane kakhulu, kuzobangelwa umsindo ongajwayelekile;

(3) Kungenzeka ukuthi usayizi wesiphakeli mkhulu kakhulu;

(4) Izingxenye ezigugile zigugile ngokungalingani, futhi isando esinomthelela sidinga ukushintshwa;

(5) I-rotor ayilingani futhi idinga ukulungiswa futhi ihlolwe ibhalansi;

(6) Hlola ukuthi amabhawodi okusetshenzwa kulengwa ezinto zokusebenza aqinisiwe futhi aqiniswe ngendlela efanele yini.

Ikakhulukazi ngenxa yokuthi ibhande lonakalisiwe, i-V-belt idinga ukushintshwa, futhi ukunakwa kufanele kukhokhwe ukuze kuqinisekiswe ikhwalithi yebhande; noma ngenxa yomhlangano ongalungile we-pulley, ama-pulleys asebenzayo futhi aqhutshwayo adinga ukulungiswa endizeni efanayo.

Izizathu eziyinhloko wukusebenza kokugcwala ngokweqile kwesikhathi eside kwenjini eyinhloko, ukuphathwa kokushisa okungafanele kwe-bearing, nobulukhuni obudlulele bezinto eziphukile. Lapho uphatha, kuyadingeka ukufaka esikhundleni se-bearing entsha, futhi unake ukugcinwa nokulungiswa okufika ngesikhathi enqubweni yokusebenza kwesikhathi esizayo.

Kusho ukuthi i-blower noma impact liner ye-crusher iguge kakhulu, okubangela igebe phakathi kwesiphephetha kanye nepuleti lomthelela ukuthi libe likhulu kakhulu. Lungisa igebe phakathi kwamarack angaphambili nangemuva, noma shintsha i-liner nesando sepuleti; lungisa indawo yokubeka umthelela ukuze izinhlangothi ezimbili zisondele emshinini Igebe phakathi kwemigqa yefreyimu lifana; uma ama-linings ohlaka agqoke kakhulu, kufanele ashintshwe ngesikhathi.

I-crusher yomthelela iyama kungazelelwe ngesikhathi sokusebenza, futhi kunezizathu eziningi zalokhu kwehluleka, njengokuvinjelwa kwembobo yokukhipha, ukushelela kwebhande, i-voltage ephansi, ukulimala okuthwalayo, njll. Lezi zinkinga kufanele ziqedwe, njengokususa ukuvinjelwa imbobo yokukhipha, ukuqinisa ibhande, ukwandisa i-voltage nokuqinisekisa ukuzinza kwe-voltage, esikhundleni sokuthwala, njll.

Isizathu esikhulu salokhu kwehluleka ukuthi intwasahlobo ayixegi lapho ichweba lokuphuma lincishisiwe. Ngakho-ke, intwasahlobo ephukile kufanele ishintshwe ngesikhathi sokulahlwa.

Misa umshini ngokushesha, hlola ukuthi kukhona yini ukungcola kwensimbi noma izingxenye eziphukile ngaphakathi kwesigxobo sokuchoboza, futhi uhlanze i-crusher cavity; hlola ukuqiniswa kwepuleti loqweqwe lwangaphakathi kanye negebe phakathi kwe-blow bar ne-lining plate, uma igebe lilincane kakhulu, lizophinde libangele umsindo ongajwayelekile .

Isizathu esiyinhloko sale nkinga ukushelela kwebhande, ukungqubuzana ne-pulley kanye nephunga lenjoloba elihlabayo, noma i-rotor ibambekile. Kuyadingeka ukuhlola i-rotor emgodini womshini futhi uyixazulule ngesikhathi.

Okungenhla amaphutha kanye nezixazululo ezivame ukwenzeka ekusetshenzisweni kwe-crusher yomthelela. Uma lokhu kwenzeka ekusebenziseni kamuva, ungabhekisela ekuhloleni okulula. Uma sikhetha i-crusher yomthelela, kufanele sikhethe ukudlula kwekhwalithi, umenzi ojwayelekile. Gwema izinkinga ezivamile kamuva, noma izimo lapho kungekho khona ukuqinisekiswa kwekhwalithi.

Add: I-Luoxin Industrial Zone, Idolobha laseLuoyang, Isifundazwe saseHenan P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com

Amptelike agent van ZY MINING in Rusland.

Skryf asseblief hier in.

Add: I-Luoxin Industrial Zone, Idolobha laseLuoyang, Isifundazwe saseHenan P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com