-

Produkte

-

Toepassing

Abstract

I-high pressure grinding roll iye yathandwa kabanzi futhi yasetshenziswa embonini yensimbi kanye nezimayini emazweni athuthuke kakhulu embonini emhlabeni jikelele. Nokho, ukusetshenziswa kwayo ezweni lakithi kuseyizinsana. Leli phepha lizokwethula kafushane isakhiwo kanye nomgomo wokusebenza we-high pressure grinding roll, izinzuzo zayo ezifana nokusebenza kahle okuphezulu, ukongiwa kwamandla nokuvikelwa kwemvelo, kanye nocwaningo lokufinyelela lokugaywa kwensimbi.

Ukwethulwa kwe-high pressure grinding roll (HPGR)

I-high pressure grinding roll iwuhlobo lwemishini yokugaya ethuthukisiwe eyakhiwa ososayensi baseJalimane ngeminyaka yawo-1980. Yaduma ngokushesha e-USA, German, Russian, Brazil, Chile, Australia kanye nezinye izifunda zezimboni ezithuthukile ngenxa yesakhiwo esilula, ukusebenza kahle kokukhiqiza okuphezulu, ukuvikelwa kwemvelo nokonga amandla kanye nesimiso sokusebenza esithuthukisiwe. Izwe lethu lethule ubuchwepheshe bokukhiqiza be-HPGR kusuka ku-KHD, Inkampani yaseJalimane. Iqale yasetshenziswa ekugayweni kukasimende okube nemiphumela esobala. Ngakho-ke, umshini wakhuthazwa kabanzi futhi wasetshenziswa. Umfanekiso 1 wuhlaka oluyinhloko lwe-HPGR olukhiqizwa ekhaya.

Ngemva kweminyaka engaphezu kwamashumi amabili yokuzijwayeza ukukhiqiza nokufunda kubuchwepheshe obethulwa, i-high pressure rolling roll isisungule uchungechunge lomkhiqizo futhi yasetshenziswa emabhizinisini kazwelonke anosayizi omkhulu omaphakathi wokugaya usimende iklinka. Kufakazelwe ukuthi i-HPGR ekhiqizwe ekhaya ingathatha indawo yalezo ezingenisiwe ngokuphelele ngemva kweminyaka yokuzijwayeza ukukhiqiza. Embonini ye-metallurgical, i-high pressure grinding roll isetshenziswe ngempumelelo ekukhiqizeni okuphakelayo kwe-pelletizing kokugaya insimbi ecolekile esitshalweni se-sintering eminyakeni yamuva futhi ezuza imiphumela emihle kakhulu. Kodwa-ke, akuzona izibonelo eziyimpumelelo ukusebenzisa umqulu wokugaya umfutho ophezulu wasekhaya ukuze kuqhutshwe insimbi yensimbi endaweni yokuhlukaniswa kwamaminerali.

(1) Indlela

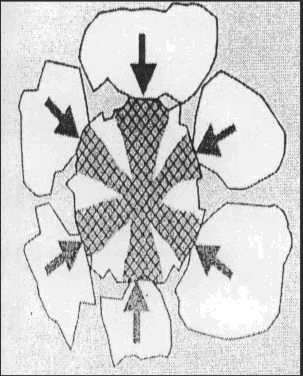

I-high pressure grinding roll iklanywe ngokulandela isimiso sokuhlukana kwezinhlayiyana yizingcindezi ezinkulu. Ingcindezi isuka kupheya lamaroli aphendukayo anobubanzi obufanayo kanye nesivinini sokujikeleza. Enye ilungisiwe kuyilapho enye ivunyelwe ukuthi inyakaze kancane ngaphambili nangemuva. Izingcindezi zisetshenzwa ezisekelweni ezithwala kuzo zombili iziphetho zomqulu ontantayo ngokusebenzisa isilinda somfutho ophezulu. Ngenkathi i-HPGR isebenza, izinto ezisetshenziswayo zingena emgodini ochotshozwayo ngamandla adonsela phansi zisuka emgqonyeni wekholomu yesitoko, bese zilunywa amaroli amabili aphenduphendukayo, aphoqelelwe ukuba angene emgodini ohlanganisayo. I-Duo ekunciphiseni kwegebe phakathi kwamaroli amabili, amandla okucindezela ayakhuphuka. Izinhlayiya ze-Material zicindezelwa yizingqimba ze-roll ngokuqondile kodwa nezinye izinhlayiya, okuholela ezinhlayiyeni ezihlangene futhi zichotshozwe ngaphambili. Uma amaroli ezungeziswa emugqeni omaphakathi ovundlile, izingcindezi zifinyelela phezulu. Izinhlayiya zichotshozwa ngamazinga ahlukene. Ngokujikeleza kwemiqulu, izinto zokwakha zikhishwa ngendlela yamaphilisi. Umfanekiso 3 ubonisa inqubo yokugaya impahla phakathi kwamaroli.

(2) Isakhiwo se-HPGR

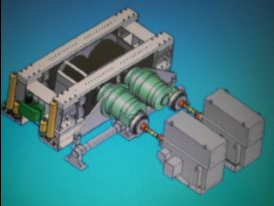

Okulandelayo ukwakheka kwe-HPGR. Idivayisi yokuphakelayo ifakwe ku-rack yozimele. Imiqulu yokucindezela ifakwe embhedeni wokubeka osekelwa ama-bearings. I-roll ngayinye inesistimu yokushayela ezimele. Amandla alethwa kuma-compress rolls ngokusebenzisa i-universal coupling, i-safety clutch kanye nesinciphisi segiya leplanethi. I-Centro-lubricating system inikezela ngamafutha okugcoba namafutha kuwo wonke ama-bearings. I-HPGR yamukela isilawuli esihlakaniphile se-PLC esiklanywe ngokulawula insimu, isilawuli segumbi lokulawula elimaphakathi, ukulawula kwesandla nokulawula okuzenzakalelayo, ukubuka zonke izinqubo zokusebenza nezinsuku zokusebenza komshini ngokuzenzakalelayo ngegumbi eliphakathi lokulawula.

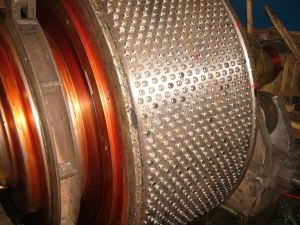

Izingxenye ze-Wear ze-HPGR ikakhulukazi ziyakhathala nge-stud ezungeze ama-compress rolls. Amathayi akhiqizwa ngensimbi ye-alloy engagugi. Izikhonkwane zisebenzisa i-tungsten carbide material.

Ngenkathi i-HPGR isebenza, ukusebenza okungagugi kwamaroli kuncike ekwakhekeni kongqimba oluzenzakalelayo lokuvikela ukugqokwa lapho izinto ezisetshenziswayo zigcwalisa izindawo phakathi kwama-studs. Izingxenye zamasondo zivikelwe ngaphandle kokuxhumana nezinsimbi ngokuqondile .

Ngakho-ke, impilo yesevisi yamasondo inganwetshwa ngempumelelo. Izikhonkwane ze-Tungsten carbide zinobulukhuni obuphezulu nokusebenza okuhle okungazweli kodwa zishwabene futhi ziqhephuka noma ziphuke kalula. Ngakho-ke, akunakugwenywa ukuphulwa noma ukulinyazwa ngesikhathi sokusebenza. Ukuhlanganiswa kwama-studs kanye nezindawo zokugoqa zemishini engenisiwe kusebenzisa ukufakwa kokuphazanyiswa ukuze izikhonkwane zilungiswe uma ziphukile.

(1) Uma kuqhathaniswa nohlobo olufanayo lwemishini, i-high pressure grinding roll iwukusebenzisa amandla aphansi ngenxa yesimiso sayo sokusebenza sokuthi ukuhlukana phakathi kwezinhlayiyana kwenza izinhlayiya zixhumane kakhulu futhi zihlanganyele kakhulu ukuze kusetshenziswe amandla ngesilinganiso esiphezulu. Ngakho-ke, ukusetshenziswa kwayo kwamandla ngokwephula ngokusobala kuphansi kunemishini evamile yokuphulwa kwezinhlayiyana eyodwa noma izinto zokugaya’. Ngokwenqubo yokukhiqiza ekhaya futhi ebanzi, eningi lama-ores, ukusetshenziswa kwawo kwamandla okuphulwa kungu-0.8-3kwh/t. uma umshini ufakwe nemishini elandelayo, ukusetshenziswa kwamandla okugaya okuphelele kunganciphisa ngaphezu kwama-40%.

(2) Ingakwazi ukucubungula izinto ezinomswakama ophezulu uma kuqhathaniswa. I-HPGR ilindele ukuthi okuphakelayo kungaqukatha umswakama othile ngesikhathi sokusebenza ukuze kube ngcono ukwakha isendlalelo esiqinile sokugqokwa kwemvelo ukuze kuthuthukiswe isimo saso sokusebenza kanye nempilo yesevisi yezindawo eziginqikayo. Isibonelo, okuqukethwe komswakama wesiphakeli kungaba kufika ku-10% uma ugaya insimbi yensimbi ukuze kufakwe i-briquetting. Lapho ugaya insimbi noma insimbi eyigugu, umuntu wangaphandle utusa ukuba umswakama ungabi ngaphezu kuka-8%.

(3) Ingathuthukisa izinga lokutakula, ukugaya kanye namandla emikhiqizo kunqubo elandelayo. Ngokusekelwe esithombeni 6, izinhlayiya ezicutshungulwe yi-HPGR, zinokuqhekeka okuncane okuningi. Izinhlayiya ezingenawo ama-micro-cracking zinengcindezi yangaphakathi ngenxa yokucindezela. Ngakho-ke, lezi zinhlayiya ziphinde zicutshungulwe esinyathelweni esilandelayo njengokungena ku-ball mill zingagaywa futhi zihanjiswe kalula, zithuthukise ukugaya kakhulu kanye nokukhiqiza kwenqubo yokulandela.

(4) Umshini unomsebenzi omncane kanye nokutshalwa kwezimali kobunjiniyela bomphakathi okuncane. I-HPGR inesakhiwo esihlangene, isisindo esincane, usayizi omncane wohlaka; ukugaya nokuchotshozwa kwawo kwenzeka phakathi kwemiqulu emibili. Ukucindezela kwe-static okukhiqiziwe kudonswa ngokuphelele yi-rack ngamandla amancane esisekelweni ngisho nangekho. Ngakho-ke, uma kuqhathaniswa nezinhlobo ezifanayo zemishini yokugaya, i-HPGR ayidingi isisekelo esiqine kakhulu esingasindisa utshalomali oluningi lobunjiniyela bomphakathi.

(5) Umshini unokudlidliza okuncane, imisindo ephansi nothuli oluncane. Ngesikhathi sokusebenza kwayo, ukugaya kuncike ekucindezelweni okumile. Uma ugaya, izinto ezisetshenziswayo zisendaweni evaliwe phakathi kwama-roll ne-feed device. Ngakho-ke, asikho isenzakalo esinomthelela kanye nokuchaphazeka kwempahla. Yingakho ukudlidliza, imisindo nothuli kuncane.

(6) Izinga layo lokusebenza liphezulu, lifika ngaphezu kwama-95%. I-HPGR yamukela ukulawulwa okuzenzakalelayo okuthuthukisiwe kanye nesistimu yokuhlola okuzenzakalelayo yokuqapha nokulawula izinkomba eziyinhloko njengezinga lokushisa, igebe le-roll, ingcindezi, umthamo wokuphakelayo, namandla angaqinisekisa ukusebenza okuvamile kohlaka oluyinhloko. Khonamanjalo, ukulwa okuhle kokuthuthumela kwempahla eqengqelekayo kanye nendawo esezingeni eliphezulu ingandisa isikhathi sokusebenza esisebenzayo kakhulu.

(7) Ukugqoka izingxenye kungasebenza isikhathi eside. Izingxenye ezigqokiwe zomshini zingamathayi phezu kwamaroli. Isendlalelo se-auto-genous wear singavikela indawo eqengqelekayo ukuthi ingathintani noma ithinteke ngezinsimbi. Imihuzuko yenzeke kakhulu ezikhonkwaneni ze-tungsten carbide ukuze impilo yesevisi yendawo eqengqelekayo inwetshwe kakhulu. Ngaphezu kwalokho, uma izikhonkwane ze-tungsten carbide ziphukile ngokwengxenye, izingxenye eziphukile zingalungiswa futhi zishintshwe. Uma kunjalo, impilo yesevisi ye-roll surface ingaba amahora angu-10000-20000. Ipuleti elingemuva elingaphansi kwekholomu yesitoko lamukela izinto ezintsha eziyinhlanganisela, futhi impilo yalo yesevisi ingaqinisekiswa ukuthi isetshenziswa isikhathi esingaphezu konyaka owodwa. Ipuleti linomthamo omncane, amakhilogremu ambalwa kuphela, okubuye kube lula ukushintshwa.

I-high pressure grinding roll isetshenziswe kabanzi ezweni lakithi iminyaka engaphezu kwamashumi amabili kusukela kwasungulwa ubuchwepheshe bayo bokukhiqiza buvela eJalimane. Ukusetshenziswa kwayo embonini yezinto zokwakha yiyona ephumelela kakhulu futhi evamile, futhi izinga lendawo liphezulu kakhulu. Ngakho-ke, izinkampani zikasimende ezifuywayo ezinkulu ezimaphakathi zonke zihlome ngemishini yokugaya umfutho ophakeme wokuzenzela futhi zithole izinzuzo zezomnotho nezinzuzo zomphakathi kahle kakhulu. Ekuqaleni kwekhulu lama-20, i-HPGR isetshenziswe embonini ye-metallurgical. I-Wuhan Iron and Steel Corp. Imboni ye-pellet yase-Chengchao yethule iyunithi yomqulu wokugaya umfutho ophezulu ovela ku-KHD Humboldt Wedag International AG ukuze isetshenziswe ekuphakeleni kwamapellets ensimbi ore nawo azuze imiphumela emihle kakhulu. Imboni ye-pellet yase-Liuzhou Iron and Steel Company, imboni ye-pellet ye-Kunming Iron and Steel Holding Corporation, imboni yokucwilisa i-Handan Iron ne-Steel group Corporation kanye ne-Shagang Group Corporation sintering plant yethulwe i-HPGR ngokulandelana ngamamodeli ahlukene kanye nenani elibizayo elizosetshenziswa ekugayeni okuphakelayo kwensimbi. Ngo-2003, i-Hangzhou Iron and Steel Group Company yacela ukusebenzisana ne-Cictic Heavy Industries Corporation ukuze icwaninge futhi ithuthukise imishini yokugaya esetshenziswa ukugaya okuphakelayo kwensimbi ukuze kongelwe izwe imali yangaphandle. Ngemva konyaka owodwa wokuhlolwa nezifundo, i-HPGR yokuqala yasekhaya esetshenziswa embonini ye-metallurgical yagcina ikhiqizwe ngempumelelo ngo-2005. Ngemva kweminyaka eminingi yokuzijwayeza ukukhiqiza, izakhiwo zayo zobuchwepheshe zase zifinyelele ezingeni lempahla ethunyelwa kwamanye amazwe.

Manje, i-HPGR eyenziwe ekhaya isetshenziswa ngokulandelana ezitshalweni ezishisayo ezifuywayo njenge-Lengshuijiang Sintering Plant, i-Tianjin Rongcheng Iron and Steel pellet plant, kanye ne-Shougang Changzhi Iron and Steel Corporation Sintering Plant. Isicelo se-HPGR embonini yokucubungula izimbiwa sasiqala ngo-2004. Kulo mkhakha, umguquli wokuqala kwakuyi-Magang Group Nanshan Mine Company Aoshan Mineral processing plant yethula i-HPGR yokuqala ezosetshenziswa ekutholeni insimbi yokugaya evela e-Germany Köppern Company. Kusukela yafakwa ekukhiqizweni ngo-2006, izinga lomkhiqizo, umthamo kanye nezindleko konke kube nemiphumela emihle ngenxa yemisebenzi yawo emihle kanye nezakhiwo. Ngemuva kwalokho, Izitshalo eziningi zokucubungula amaminerali ezifana neShanxi Jinduicheng Molybdenum Group Baihualing Mineral Processing Plant, iSijiaying Mine Company Iron Processing Plant, iShandong Gold Group Sanshan Island Gold Ore Processing Plant, iMagang Heshangqiao Iron Processing Plant kanye neHuoqiu Zhangzhuang Ore Processing Plant nokunye, yethule amamodeli ahlukene e-high pressure grinding roll eyodwa ngemva kwenye evela eJalimane okuphinde kwabangela ukuthi imali eningi yangaphandle ingene kwamanye amazwe. Ngaleso sikhathi, kuphinde kwavusa umdlandla wabakhiqizi bakazwelonke ukuthi bacwaninge futhi baxhaphaze i-HPGR yasekhaya esetshenziselwa ukucubungula izimbiwa. Sikholelwa ukuthi umqulu wasekhaya wokugaya umfutho ophezulu uzosetshenziswa embonini yokucubungula izimbiwa kakhulu esikhathini esizayo esiseduze.

Inkampani yethu yaqala ukucwaninga nokuthuthukisa i-HPGR eyasetshenziswa ekubhidlizeni insimbi ngo-2008 futhi yakhiqiza iyunithi ye-GM52-14 HPGR yokuhlolwa. Senze izivivinyo eziningi zezitshalo zokucubungula amaminerali njenge-Shougang Tonggang Group Concentrator, i-Indonesia Concentrator kanye ne-Henan Dongda Concentrator, ehlinzeka ngesisekelo sobuchwepheshe esithembekile sokukhethwa kwamamodeli, ukudweba inqubo yokukhiqiza yobuchwepheshe kanye nemikhiqizo yokuklama.

Kulokhu okulandelayo, sithatha nje ukuphulwa kwe-iron ore yase-Indonesia njengesibonelo ukwethula ukuhlolwa kokugaya:

Sigunyazwe inkampani yezimayini yase-Indonesia, sahlola ukucubungula insimbi emayini yabo ngomshini wokugaya onengcindezi ephezulu.

A. Usayizi wensimbi

Insimbi eyanikezwa imayini yase-Indonesia yayihlukile ukusuka ku-20mm kuya ku-150mm. Ibanga lensimbi nokwakheka ngaphakathi kwensimbi bekungacacile. Izinsimbi zavezwa enkampanini yethu ngendiza .

B. Okuqukethwe umswakama kwensimbi

Ngaphambi kokulethwa, umswakama wawungaba ngu-11%. Ngenxa yokucaciswa kwamazwe ngamazwe, ukugunyazwa kwamasiko kanye nokuhlolwa nezinye izinqubo eziyisicefe, kuthathe cishe inyanga eyodwa ukuthumela insimbi evela e-Indonesia kithi. Ngaphandle kwalokho, ngenxa yesimo sezulu sezwekazi, umswakama wensimbi wawungu-3.8% kuphela ngokuhlolwa ngemva kokufika enkampanini yethu.

C. Ukuqina kwensimbi

Ubulukhuni be-Ore obulethiwe bebuhlukile. Kulezi zithambile, i-protodyakonov coefficient yamandla edwala yayiyi-4 kuya ku-6 kuphela, eyayichotshozwa kalula ngesando sesandla. Kwabanzima, bekungu-13 kuya ku-17 amabanga abehlukene ukuze agaywe.

A. Okuqukethwe umswakama kwensimbi

Ukuze sibuyise umswakama we-ore yase-Indonesia, sifaka ama-ore anomswakama ongu-3.8% emanzini izinsuku eziyishumi (bheka isithombe 2). Khona-ke umswakama wayo wawungu-11% ngokuhlolwa owawucishe ufane nezinsimbi zangempela ngaphambi kokulethwa. Lokho kuzoqinisekisa ukuthi ukuhlolwa kuthembekile.

B. Osayizi bensimbi

Ngokwenqubo yezobuchwepheshe yase-Indonesia, usayizi wokudla kufanele ube ngu-30-40mm we-HPGR. Ngakho-ke, ama-ore achotshozwa ngokusekelwe ezidingweni ezingenhla ngama-aggregate agayiwe amancane.

Esivivinyweni, umswakama we-ores ube nezinhlobo ezimbili, ophansi kakhulu u-3.8% no-11% ophezulu kakhulu. Kuthathe ama-ores angu-60kg kulokhu kuhlolwa. Futhi u-20kg wawuyinsimbi enomswakama ongu-3.8% kanti u-40kg wawunomswakama ongu-11%.

Izinhlayiya ezicutshungulwa yi-HPGR zihlukaniswa ngokosayizi wazo ukuze kubonwe umphumela wokugaya.

Cwaninga imiphumela ephukile yensimbi yensimbi yase-Indonesia ecutshungulwe yi-HPGR kanye kanye nokusetshenziswa kwemishini;

Ubuningi. umswakama wezinto ezicutshungulwa yi-HPGR kufanele ube ngaphansi kuka-10% ekhaya naphesheya. Mayelana nensimbi yensimbi yase-Indonesia, umswakama wayo ubungaphezu kuka-10%. Ingabe bekufanele yini ukuthi kusetshenzwe yi-HPGR? Leso futhi kwakuyisihloko sokuxoxa esivivinyweni;

Yonke imingcele yokucubungula kanye nezinkomba zobuchwepheshe ze-HPGR ezisetshenziselwa ukucubungula insimbi yensimbi yase-Indonesia.

Hlola isimo se-microscopic semikhiqizo yokugcina evela ku-HPGR.

GM52-14 High pressure ukugaya roll umshini umzila;

φ200mm uchungechunge lwesikrini esijwayelekile;

Ibhalansi ye-electron ye-JA5102;

101-1Ttype dryer;

500kg yesikhulumi sesikali;

I-crusher yesando esincane somzila;

Isibonakhulu se-electron.

Roll ububanzi: φ520mm

Roll ububanzi: 140mm

Isivinini sokujikeleza: 9-15rpm

Ingcindezi yokuhlola: 10Mpa

Igebe langempela phakathi kwemiqulu: 3mm

Izinhlobo ezimbili zamatshe: okuqukethwe umswakama 3.8% kanye 11%. Izinhlobo ezimbili zensimbi zacutshungulwa ngokuhlukana yi-HPGR. Imikhiqizo yokugcina kwakuyikhekhe le-flake lempahla evela kuzo zombili izinhlobo zezinto ezinosayizi ohlukile. Kwakungekho impahla yamandla;

Ngokuphathelene nale mikhiqizo yokugcina ye-flake, kwakungekho mehluko omkhulu phakathi kwe-ore enomswakama ophezulu kanye ne-ore encane yomswakama, kungakhathaliseki ubukhulu noma ukuma. Ububanzi be-Flake babungaba ngu-50mm, futhi ukujiya kwakungaphansi kuka-12mm. kuyilapho kwakukhona umehluko phakathi kokubumbana nobulukhuni. I-Flake enomswakama ophansi yayiqinile futhi ihlangene, uma iqhathaniswa nempahla ephezulu yomswakama. Womabili ama-flakes ayeqinile futhi kunzima ukuchotshozwa ngomunwe.

Usayizi we-ore ubumuhle kakhulu ngemuva kokuthi izinhlayiya ze-flake zichotshozwe umshini wokugaya isando we-trail. Usayizi wayo ubunjengokulandelayo ngemuva kokuhlolwa:

☆ usayizi wezinhlayiyana ≤1mm cishe 84%

☆ usayizi wezinhlayiyana ≤2mm cishe 7%

☆ usayizi wezinhlayiyana >3mm<5mm mayelana 9%

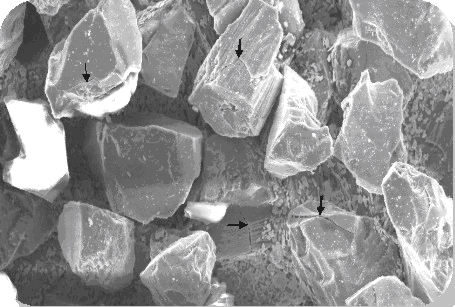

Ukuqhekeka okuncane kutholwe ngaphakathi kwemikhiqizo ye-ore ecutshungulwa umqulu wokugaya onengcindezi ephezulu ngaphansi kwesibonakhulu esinamandla amakhulu ngaphandle kwezinguquko ezisobala ze-macroscopic.

Ama-ore anosayizi ohlukile akhishwe ngendlela ye-flake ngemuva kokucutshungulwa yi-HPGR. Ngokuvamile amakhekhe e-flake ayephulwa kalula. Nokho, le nsimbi yase-Indonesia yayinzima kakhulu. Sihlaziye ngaphambilini ukuthi kwakukhona izinto ze-viscous ngaphakathi kwe-ores njengoba singahlolanga ukwakheka kwezinsimbi.

Ukuhlolwa okwenziwa insimbi yase-Indonesia enomswakama ongaphezu kuka-10% kucutshungulwe umshini wokugaya umfutho ophezulu kwaneliseka kungakhathaliseki usayizi, umthamo noma ukuguquguquka kwempahla ye-HPRG. Ngakho-ke, mayelana nenkinga yokuqukethwe komswakama kokuphakelayo kwe-HPGR, asikwazanga ukunqwabelanisa ngaphansi kwekhanda elilodwa. Kungcono senze isiphetho ngemva kokuhlolwa ngokusekelwe ezintweni ezihlukahlukene. Ngakho-ke, izinto ezinomswakama ophezulu zingasetshenzwa ngaphandle kwenqubo eyomile ebizayo engathuthukisa umthamo kakhulu futhi yonge imali enkulu yokukhiqiza.

I-matrix yensimbi yensimbi yahlukaniswa ngisho nempushana ngemva kokucutshungulwa umqulu wokugaya onengcindezi ephezulu. Izinsimbi ezinezinga eliphezulu lensimbi zaba izinhlayiya ezinhle. Ezinye izinhlayiya zafakazelwa ngokuqhekeka okuningi kwangaphakathi ngemva kokuhlolwa.

(a) Ukuhlolwa kwafakazela ukuthi kwakulungile ukukhetha i-HPRG njengesisetshenziswa sesibili sokuchotshozwa kwensimbi ekhethekile yase-Indonesia. Umsebenzisi kufanele azuze izinzuzo ezinkulu zezomnotho nezenhlalo;

(b) Umqulu wokugaya umfutho ophezulu ungacubungula izinto ezinomswakama ongaphezu kuka-10%. Kodwa kungaba ngcono ukuthatha isinqumo ngemva kokuhlolwa kwezinto ezahlukene.

(c) Idethi engcono kakhulu yokucubungula yensimbi ayikwazi ukuqinisekiswa ngenxa yezinto ezincane ekuhlolweni. Kodwa-ke, kwafakazelwa ukuthi umqulu wokugaya umfutho ophezulu wawufaneleka ngokuphelele ukucubungula insimbi yensimbi.

(d) Insimbi yensimbi ecutshungulwe yi-HPGR yayinokuqhekeka okuncane ngaphakathi okungathuthukisa ukukhiqiza komsebenzi olandelayo futhi kunciphise ukusetshenziswa kwamandla ngempumelelo.

Add: I-Luoxin Industrial Zone, Idolobha laseLuoyang, Isifundazwe saseHenan P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com

Amptelike agent van ZY MINING in Rusland.

Skryf asseblief hier in.

Add: I-Luoxin Industrial Zone, Idolobha laseLuoyang, Isifundazwe saseHenan P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com