-

Produkte

-

Toepassing

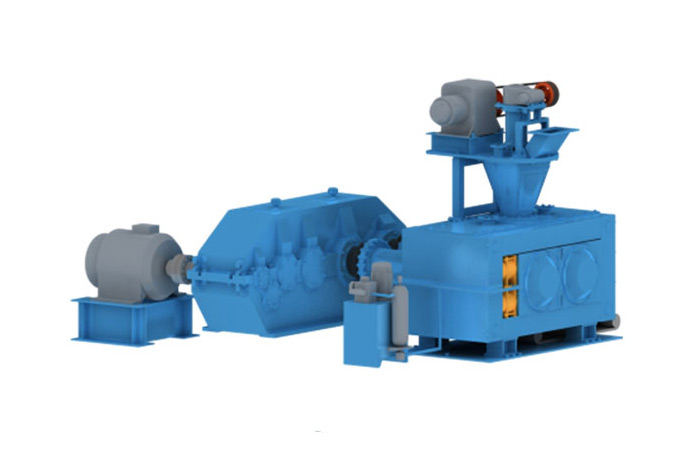

Ekukhiqizweni kwezimboni zanamuhla, ukuze kugcinwe izinto zokusetshenziswa, imishini ehlukahlukene ezimbonini ezahlukahlukene ivela emfudlaneni ongapheli. Njengesisetshenziswa esibalulekile sokucubungula izinto ezisele, ukucindezela nokusebenzisa kabusha, akunakugwemeka ukuthi ukuguga nokuguga okuhlukahlukene kuzokwenzeka ngesikhathi sokusetshenziswa. Izingxenye ezibalulekile zokusebenza emshinini we-briquetting isikhumba se-roller sivame ukushintshwa ngemva kokuguga.

Isikhumba se-roller siyilungu le-cylindrical elinamabhola kanye nezisekelo ezimbiwe ebusweni be-roller core yomshini wokubopha. Ngokuvamile, ukucindezelwa kwezinto kuncike kuma-hydraulic drive rollers, akhiwa amabhola esikhumba se-roller, njengendlela yokugcoba okulula kakhulu ukugqoka. Ukushintshwa okwenziwa njalo akwamukelekile kubaqhubi, kodwa isikhumba somshini we-briquetting esigugile asikwazi ukuhlangabezana nezidingo zokukhiqiza, futhi akunakwenzeka ukukwenza ngaphandle kokushintshwa. Ngakho-ke, kubaluleke kakhulu ukugcina isikhumba se-roll ngesikhathi sokusetshenziswa. Umshini othize wokufaka i-briquetting Iyiphi indlela yokunakekela isikhumba esinamasondo?

Kunezindlela ezine zokufaka isikhumba se-roller somshini we-briquetting. Imishini ye-briquetting ehlukene isebenzisa izindlela ezahlukene, kodwa izindinganiso zokufaka ziyafana. Okuningi mayelana nokukhiqiza, ukuma kwesokhethi yebhola esikhumbeni se-roller kufanele kuhambisane, ngaphandle kwalokho umshini we-briquetting ngeke ukhiqize ibhola, amabhola avulekile, futhi ibhola alilona iqiniso; ngesikhathi esifanayo, ngenxa yokuthi isikhumba se-roller kanye nesokhethi yebhola akuhambisani, ibhola lisazoba yibhola. Imiphetho yesokhethi iyaguga, futhi ama-roller kufanele ashintshwe ngemva kwesikhathi eside.

Insimbi ejwayele ukusetshenziselwa ukuphonsa isikhumba somshini we-briquetting yi-65 manganese alloy, kanti insimbi ejwayele ukusetshenziselwa ukubumba isikhumba somshini we-briquetting yi-92 chromium molybdenum. Inkampani yethu isebenzisa izinto zokwakha ezisezingeni eliphakeme—ezinensimbi. Izikhumba ze-casting roller azigqoki, kodwa inzuzo ilele ezindlekweni zazo eziphansi. Abanye opharetha ababi ngemali, futhi akuyona into enkulu ukushintsha izikhumba ze-roller njalo, kodwa opharetha abasebenzisa izikhumba ze-roller ezibunjiwe, isikhumba se-roller sihlala isikhathi eside, singcono. Kungcono ukungashintshwa, kodwa indlela yokugcinwa kwesikhumba se-roller yomshini we-briquetting ayivunyelwe.

Ngemuva kokuthi isikhumba se-roller sifakwe ngendlela efanele, uma ufuna ukunciphisa izinga lokugqoka kwesikhumba se-roller, kufanele uthathe izinyathelo ezithile zokuzivikela ngaphambi kokuba imishini isebenze. Omazibuthe kufanele bafakwe ku-conveyor yebhande lokuphakela ukuze kuvinjwe insimbi eqinile ukuthi ingangeni esikhumbeni se-roller futhi yenze isikhumba se-roller sinamathele. Enqubweni yokuthuthwa kwezinto ezibonakalayo, abasebenzi kufanele bakhethe amatshe ngesikhathi, futhi baqinisekise ukuthi usayizi wezinhlayiyana wezinto ezibonakalayo ungaphansi kuka-3 mm, ukuze ngenkathi eqinisekisa impilo yesevisi yesikhumba se-roller, futhi angaqinisekisa ukuthi kuzoba khona. ungabi nezinkinga ekwakhiweni kwezinto; Ngaphambilini, abasebenzi bekufanele bahlole amaroli emishini yokubopha ukuze babone ukuthi akukho yini ukuxega noma ukuchezuka. Uma lesi simo senzeka, ukuqhubeka nokusebenza kuzokwenza kalula ukuthi umqulu uphuke, futhi ukulahlekelwa kungaphezu kwesikhumba se-roll.

Idivayisi yokuvikela umshini wokudonsa amanzi ingenye yezinhlaka zomshini wokwenza i-briquetting. Ngenkathi kunikeza ingcindezi yokukhiqiza edingekayo yamaroli, kungabangela nokuphakelayo ngokweqile phakathi kwamaroli noma amabhlogo ensimbi lapho i-piston rod yesilinda esisebenza nge-hydraulic icindezelwa futhi ilayishwa ngokweqile. Umphumela wokuvaleka kwephampu ye-hydraulic kanye noshintsho lwengcindezi kwenza isiqoqelilwazi sidlale indima ye-buffer, futhi ngesikhathi esifanayo i-valve yokuchichima iyavuleka ukubuyisela uwoyela ukuze uhambise i-piston rod, ngaleyo ndlela kwandise igebe phakathi kwamaroli amabili. Lolu chungechunge lwezenzo lwenza izinto eziqinile zidlule kumaroli ukuze kuqinisekiswe ukuthi umqulu Awusekho umonakalo omkhulu.

Uma ufuna ukuthi idivayisi yokuvikela ugesi idlale indima yayo efanele, kuyadingeka ukwenza umsebenzi wokulungisa ojwayelekile. Ngesikhathi somsebenzi, ukunikezwa kokucindezela kwedivayisi ye-hydraulic kufanele kube okunengqondo, ukushaywa akufanele kube ngokweqile, futhi izinga lokushisa lamafutha we-hydraulic akufanele libe phezulu kakhulu noma phezulu. Ezikhathini ezijwayelekile, uwoyela we-hydraulic kufanele uhlungwe njalo. Uma kukhona ukungcola emafutheni, kulula ukulimaza izimpawu. , Okubangela ukungasebenzi kahle, ngisho nokuklwebheka kusilinda esiyinhloko.

Indawo yokukhiqiza ehlanzekile ingaqinisekisa ukuthi abasebenzi banesimo sengqondo esihle sokusebenza emsebenzini. Kumelwe bahlanze ngokuhlanzeka ngemva komsebenzi wansuku zonke. Ngaphandle kokuhlanza umhlabathi, ukuhlanza imishini nakho kungenye yezindlela zokugcinwa kwesikhumba se-roller yomshini we-briquetting. Kukhona uthuli oluningi. Kulula ukubangela uthuli ukuba luqoqe ezingxenyeni ezihambayo zemishini kanye nezingxenye eziveziwe zokuthwala. Uma ingahlanjululwa isikhathi eside, izothinta ukuphepha nokukhiqiza okuvamile, futhi ibangele nokulimala kwemishini; ezinye izinto ezicindezelwa umshini wokubopha ziyagqwala. Lapho imishini ihlanzwa, izinto ezisele esikhumbeni se-roller kanye ne-socket yebhola kufanele zihlanzwe ukuze kuvinjelwe isikhumba se-roller singagqwali isikhathi eside, okuzodala umonakalo esikhumbeni se-roller.

Amptelike agent van ZY MINING in Rusland.

Skryf asseblief hier in.

Add: I-Luoxin Industrial Zone, Idolobha laseLuoyang, Isifundazwe saseHenan P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com