-

Products

-

Application

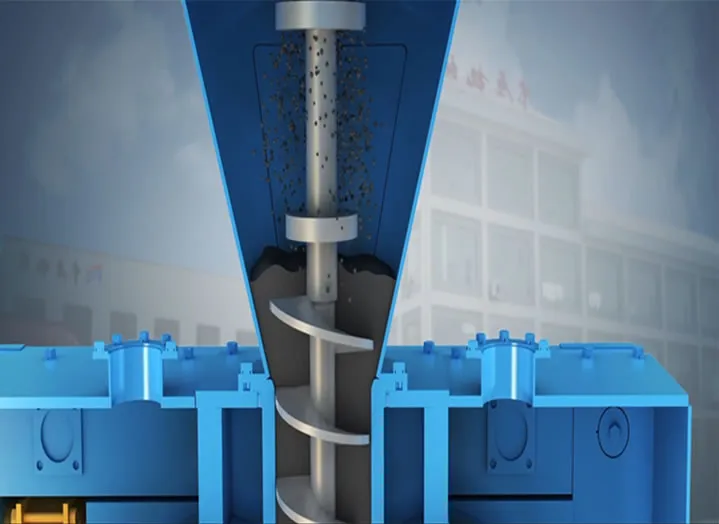

The materials are pressed into the pre- press device of the ball press with certain volume evenly when working, and the stable material position shall be kept in the pre-press device.

The pre-pressing spring in the device will force the materials into the inter-space between the double rollers, then the materials shall be pre-pressed and transited to the arch groove of the pair-rollers.

The roller pits with the same shape are distributed evenly on the rollersurface. The 2 pair-rollers shall rotate at constant speed reversely through engagement drive. The rollers will suck the materials at the entry into the groove and forcibly compress them.

With the continuous rotation of the pair-roller, the ball shall be taken off by the elastic force and gravity. The roller rotates to compress and form the materials periodically with the continuous operation of the motor to realize the batch production.

Add: Luoxin Industrial Zone,Luoyang City,Henan Province P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com

Official Agent of ZY MINING in Russia.

Please enter here.

Add: Luoxin Industrial Zone,Luoyang City,Henan Province P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com