-

Produkte

-

Toepassing

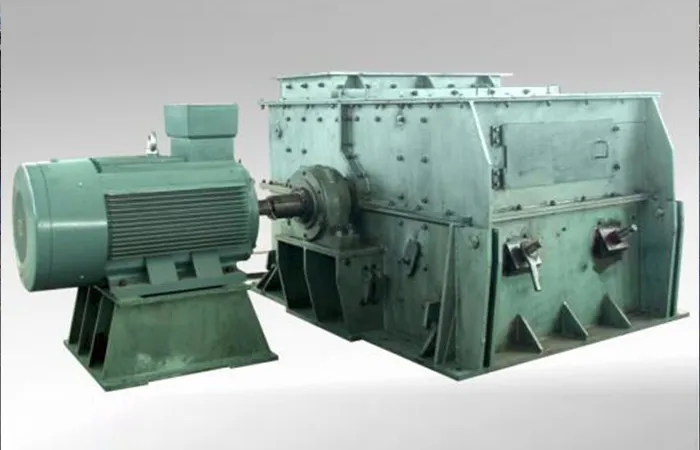

I-crusher isando isetshenziswa kakhulu ezimayini, zikasimende, zamalahle, ezensimbi, nezimboni zokwakha ukuchoboza izinto eziphukayo ezifana ne-limestone, i-slag, namalahle. Ukuqinisekisa ukusebenza okuzinzile, ukwelula impilo yemishini, kanye nokunciphisa isikhathi sokuphumula, ukunakekelwa okufanele kubalulekile.Ukugcina i-crusher yesando kubalulekile ekusebenzeni kwayo okuphelele, ukuphila isikhathi eside, nokusebenza okuphephile.

Izando Nezando:

Ukuhlola Okubonwayo: Bheka imiphetho eyindilinga, efiphele, echotshoziwe, imifantu, noma amafracture.

Ukuzungezisa: Izando zivame ukuba nemiphetho eminingi ehlabayo (indlela engu-2 noma engu-4 ebuyiseleka emuva). Jikelezisa onqenqemeni olusha lapho owamanje usugugile. Lokhu kukhulisa isikhathi sabo sokuphila.

Ukushintsha: Shintsha izando lapho zonke izinqe zokusika ziyindilinga noma zikhombisa ukuguga ngokweqile noma ukulimala. Shintshanisa izando kumasethi alinganiselayo efekthri ukuze uvimbele ukungalingani.

I-Hammer Rods: Hlola ukugxusha noma ukugqokwa. Faka esikhundleni uma i-grooving ikhona, ikakhulukazi uma ushintsha izando zilandelana.

Izikrini/Ama-Sieve Plates nama-Bar Grates:

Ukugqokwa Nokulimala: Hlola izimbobo, izinyembezi, ukuvaleka ngokweqile, noma izimbobo ezinde.

Ukuhlanza: Susa njalo izinto zokwakha ukuze uqinisekise ukusebenza kahle.

Ukushintshwa: Shintsha izikrini noma ama-bar grates uma agugile noma alimele, njengoba izimbobo ezigugile ziholela kusayizi wezinhlayiyana ongahambisani.

I-Wear Plates/Liner:

Ukunciphisa: Hlola njalo ukuze uthole izimpawu zokuncipha, ikakhulukazi eduze kwamabhawodi.

Ukushintshwa: Shintsha amapuleti okugqoka lapho ekhombisa izimpawu zokuzaca ukuze kuvikelwe indlu enkulu.

Ama-Bearings:

Izimpawu Zokugqoka: Hlola izimpawu zokuguga, ukushisa ngokweqile (ukushisa okudlulele, izinga lokushisa eliphezulu ngokungavamile), noma ukudlidliza. Lalela ukukhala okungajwayelekile noma ama-squeaks.

Ukugcotshwa: Ukuthambisa okufanele kubalulekile. Bheka imihlahlandlela yomkhiqizi wohlobo lwe-lubricant enconyiwe kanye neshejuli. Gwema ukugcotshwa ngokweqile.

Ukushintsha: Faka esikhundleni noma yimaphi ama-bearings awonakele noma agugile ngokushesha, ngokuvamile ngamapheya.

I-Motor Coupling:

Ukuqondanisa: Hlola ukuhlangana kwemoto nokuma kwayo njalo ezinyangeni eziyisi-6-12. Ukungaqondi kahle kungabangela ukudlidliza.

Ama-Fasteners: Qinisekisa ukuthi amabhawodi okukhweza nawokuhlanganisa aboshwe ngokuqinile.

Amabhande:

Ukushuba: Hlola ukushuba kwamabhande okushayela njalo. Lungisa njengoba kudingeka ukuze uvimbele ukushelela futhi uqinisekise ukudluliswa kwamandla okufanele.

Gqoka: Hlola imifantu noma izimpawu zokuguga.

Ama-Fasteners (Amabhawodi, Amantongomane):

Ukuqina: Hlola njalo futhi uqinise wonke amabhawodi, amantongomane, nezixhumi kumanani wetorque anconyiwe. Izinto zokubopha ezixegayo zingaholela ekudlidlizeni nasekulimaleni.

Ukungena komoya:

Ukuhlanzeka: Qinisekisa ukugeleza komoya ngendlela efanele emshinini wokugaya. Ukungahambi kahle komoya kunganciphisa isivinini somkhiqizo nokusebenza kahle kukonke.

Izihlungi: Gcina futhi uhlole izihlungi zomoya.

Abaqondisi bokugeleza:

Ukuhuzuka: Hlola izimpawu zokuhuzuka noma ukuguga, njengoba izinto ezijikelezayo zingaziqeda amandla. Shintsha njengoba kudingeka (imvamisa njalo ezinyangeni eziyi-18-48).

Izinqola Zesikrini:

I-Wear and Impact: Hlola umonakalo ogugile nomthelela, ikakhulukazi ezinhlelweni ezithile (isb., ukugaya ukudla kwezilwane ezifuywayo). Faka esikhundleni uma konakele ukuze uvimbele ukuvuza nokugcina ukusebenza.

Imoto:

Ukulayisha ngokweqile: Qinisekisa ukuthi umthwalo wemoto aweqi inani lawo elilinganiselwe.

Ukuxhunywa kukagesi: Hlola ukuthintana kahle kukagesi.

Landela Izincomo Zomkhiqizi: Lokhu kubalulekile. Imishini nezingxenye ezahlukene kudinga izinhlobo ezithile kanye namanani okothambisa.

Ukugcotshwa Okujwayelekile: Gcoba ama-bearings nezinye izingxenye ezihambayo njalo ukuze unciphise ukungqubuzana nokuguga, andise ubude bazo bempilo.

Gwema Ukugcotshwa Kakhulu: Amafutha amaningi angabangela izinkinga ezifana nokushisa ngokweqile. Ngokuvamile, gcwalisa amagumbi okuzala ku-1/3 kuya ku-1/2 wevolumu yawo.

Ukuhlanzeka: Hlanza amafutha amadala kumabhereyidi nasezigxivizweni ngaphambi kokwengeza okokugcoba okusha.

Ukuhlanza Okuvamile: Gcina umshini uhlanzekile ngokususa njalo ukungcola, uthuli nemfucumfucu. Ukunqwabelana kungabangela umonakalo, kunciphise ukusebenza, futhi kuholele nasekuhlulekeni.

Sula Ukuvala: Uma kwenzeka ama-clogs (isb., phakathi kwemicu yesisefo), misa umshini futhi uwahlanze.

Ukushintsha Okufike Ngesikhathi: Shintsha izingxenye ezigugile noma ezilimele ngokushesha ukuze uvimbele ukulimala okwengeziwe emshinini, ugcine ukusebenza kahle, nokuqinisekisa ikhwalithi yomkhiqizo.

Izingxenye Zangempela: Sebenzisa izingxenye zangempela ezishintshayo ukuze uvimbele umonakalo futhi uqinisekise ukuhambisana.

Amasethi Abhalansile: Uma ushintsha izando, hlala uzimisele ngamasethi alinganayo ukuze ugcine ibhalansi ye-rotor futhi uvimbele ukudlidliza.

Ukusabalalisa Usayizi Wezinhlayiyana: Gada usayizi wezinhlayiyana okukhiphayo ukuze uqinisekise ukuvumelana. Usayizi wezinhlayiyana ongahambisani ungabonisa izando ezigugile noma izikrini.

Ukusetshenziswa kwamandla: Ukwenyuka kokusetshenziswa kwamandla kungabonisa izinkinga ezifana nezingxenye ezigugile, ukuvinjelwa, noma umshini ogcwele kakhulu.

Ukusebenza Kukonke: Landela umkhondo ukusebenza kahle kukonke komshini ukuze uthole izinkinga kusenesikhathi.

Ukudlidliza Nomsindo: Naka noma yikuphi ukudlidliza okungajwayelekile noma imisindo, engabonisa izinkinga ezifana namarotha angalingani, amabhawodi axegayo, noma amabhere agugile.

Ukukhiya/Ukuphuma: Ngaso sonke isikhathi sebenzisa izinqubo zokukhiya/zokuphuma ngaphambi kokwenza noma yimuphi umsebenzi wokulungisa noma wokulungisa ukuze uvimbele ukuqalisa ngephutha.

Landela Imanuwali: Zijwayeze futhi ulandele ngokuqinile imiyalelo yomkhiqizi yokusebenza nokunakekela.

Ibanga eliphephile: Gcina ababukele bekude nomshini ngesikhathi sokusebenza.

Izinto Zangaphandle: Vimbela ngokuqinile ukuphakela izinto zensimbi zangaphandle kusigxobo. Uma etholakele, yima ngokushesha futhi uwasuse.

Ungeqi Umthamo: Ungalokothi weqe umthamo onconyiwe womshini ukuze ugweme ukulayishwa ngokweqile kanye nokulimala okungaba khona.

Isheduli Yokulondolozwa Kokuvikela: Misa futhi unamathele kushejuli yokulungisa yokuvimbela evamile ehlanganisa ukuhlolwa okujwayelekile, ukugcotshwa, nokushintshwa okusebenzayo kwezingxenye ezigugile.

I-Spare Parts Inventory: Gcina isitokwe sezingxenye ezijwayelekile ezigqokwayo (izando, izikrini, ama-bearing, ama-sando rods, amapuleti okugqoka) ukuze unciphise isikhathi sokuphumula.

Ukuqeqeshwa: Qinisekisa ukuthi opharetha kanye nabasebenzi abalungisayo baqeqeshwe ngendlela efanele ekusebenzeni, ukuhlola, kanye nezinqubo zokunakekela.

Ngokulandela le mihlahlandlela, unganweba ngokuphawulekayo ubude bempilo ye-crusher yakho yesando, uthuthukise ukusebenza kahle kwayo, futhi uqinisekise indawo yokusebenza ephephile.

Add: I-Luoxin Industrial Zone, Idolobha laseLuoyang, Isifundazwe saseHenan P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com

Amptelike agent van ZY MINING in Rusland.

Skryf asseblief hier in.

Add: I-Luoxin Industrial Zone, Idolobha laseLuoyang, Isifundazwe saseHenan P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com