-

Produkte

-

Toepassing

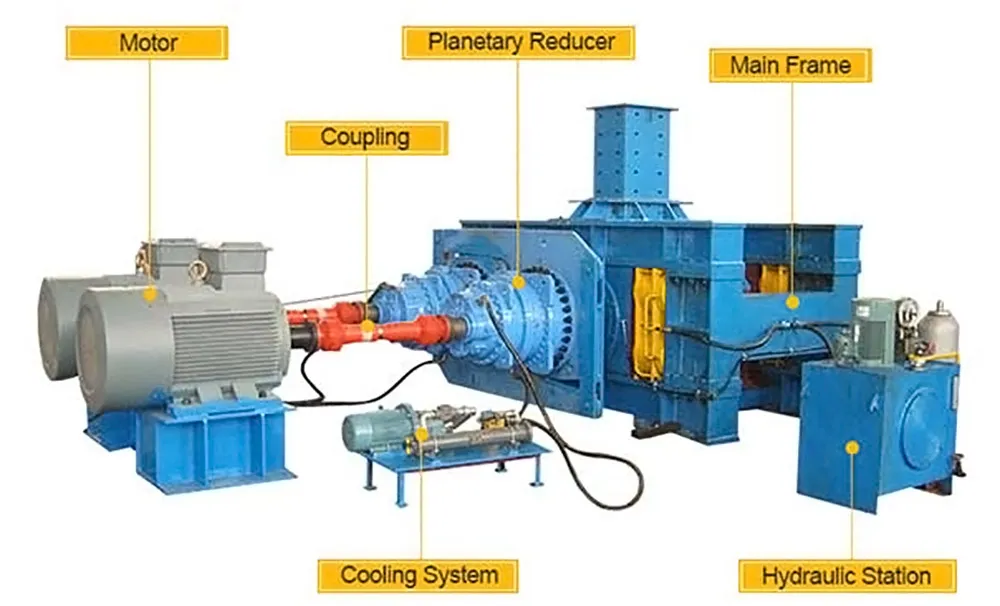

Amaroli okugaya anengcindezi ephezulu (ama-HPGR), okokusebenza okuyisisekelo okugaya ezimbonini ezifana nosimende, izimayini, nokusansimbi, yizingxenye ezibalulekile ezithwala ingcindezi enkulu. Kodwa-ke, ngaphansi kwesikhathi eside, ukusebenza komthwalo ophezulu, i-HPGR roller surface wear iyinkinga engenakugwemeka. Ukugqoka akunciphisi ukusebenza kahle kokukhiqiza kuphela futhi kukhuphule ukusetshenziswa kwamandla, kodwa futhi kungabangela isikhathi sokuphumula kanye nokulahlekelwa okukhulu kwezomnotho. Ukulungisa i-roller surface ngendlela ephumelelayo futhi engabizi sekuyindaba esemqoka embonini.

Lesi sihloko sinikeza ukuhlaziya okujulile kobuchwepheshe bokulungisa i-roller surface ye-HPGR, okukusiza ukuthi ukhethe isisombululo esifanele kakhulu sokwelula impilo yemishini nokuthuthukisa ukusebenza kahle kokukhiqiza.

Ukuqonda I-Roller Surface Wear: Kungani Ukulungisa Kudingeka?

Ngesikhathi sokusebenza, izinto eziku-HPGR zingaphansi kokucindezelwa okukhulu kanye nokugunda phakathi kwamarola amabili aphenduphendukayo. Lokhu kungqubuzana okungapheli kanye nomthelela kancane kancane kukhula imigodi, imifantu, nemifantu endaweni eyi-roller. Uma kungalungiswanga ngokushesha, ukuguga kuzoba kubi kakhulu, kuthinte ukusebenza kahle kokucolwa kwempahla futhi okungase kuholele ekuchithekeni kwe-roller surface kanye nokulimala okukhulu kwezinto zokusebenza.

Ukulungiswa kwe-roller surface kungaphezu nje kwe-"patch" elula. Kubandakanya ukubuyisela ubukhulu boqobo bendawo yerola kanye nezakhiwo ezingagugi ngezinqubo ezikhethekile nezinto ezingagugi, okuvumela ukuqhubeka nokusebenza kahle nokuzinzile.

Njengamanje, ubuchwepheshe obujwayelekile bokulungisa amarola we-high-pressure high-pressure grinding roller (HPGR) emakethe yilaba okulandelayo:

Ukulungiswa kwe-Hardface kuyindlela esetshenziswa kakhulu futhi efakazelwe yokulungisa indawo engaphezulu. Kusetshenziswa umthombo wokushisa njenge-arc noma i-plasma, intambo yengxubevange engagugi eyakheke ngokukhethekile ifakwa endaweni eyirola egugile, yakhe ungqimba olusha, olungagugi kakhulu.

Izinzuzo Zezobuchwepheshe:

I-High Wear Resistance: Ukusebenzisa izinto ezikwazi ukumelana ne-HPGR ezifana ne-high-chromium cast iron and high-carbon, high-alloy steel, indawo yerola elungisiwe ibonisa ubulukhuni obuphezulu nokumelana nokuguga, inweba impilo yayo yesevisi idlule kude indawo yokuqala.

Ukunemba Okuphezulu Kokulungisa: Ngokusebenzisa imishini yokulungisa i-CNC hardfacing, ukujiya nokuma kwesendlalelo se-weld kungalawulwa ngokunembile ukuze kuqinisekiswe ukuthi i-roller surface flatness.

Ukusebenza Kwezindleko: Uma kuqhathaniswa nokushintsha isethi ephelele yamarola, ukulungisa imbondela kubiza kakhulu futhi kudinga izikhathi ezimfushane zokushintsha, kunciphisa kakhulu isikhathi sokuphumula kanye nezindleko zokunakekela.

Ukugeleza Kwenqubo:

Ukwelashwa kwangaphambili: Hlanza, khipha amafutha, futhi ushise kuqala indawo egugile.

Imbondela: Sebenzisa okokusebenza kwembondela okuzenzakalelayo ukwenza izendlalelo eziningi zokumbondela.

Ukuqeda: Indawo yerola emboziwe yenza imisebenzi yokuqedela efana nokujika nokugaya ukuze kuzuzwe ubukhulu obufunekayo kanye nokuqedwa kwendawo.

Ukuhlola: Ukuhlolwa okungacekeleki phansi kwenziwa endaweni yerola elungisiwe ukuze kuqinisekiswe ikhwalithi yokulungisa.

Ukulungisa isifutho esishisayo kuhlanganisa ukushisisa into ekwazi ukumelana nokuguga kuyimpushana noma intambo yocingo iye endaweni encibilikisiwe noma encibilike kancane kusetshenziswa indlela yomlilo, i-arc, noma i-plasma. Izinto ezisetshenziswayo zibe sezifuthwa endaweni ye-roller ngesivinini esikhulu, zenze ukunamathela okuminyene.

Izinzuzo Zezobuchwepheshe:

Isivinini Sokulungisa Ngokushesha: Inqubo yesifutho esishisayo ilula, futhi isikhathi sokulungisa sifushane.

Ayikho Indawo Ethintekile Ukushisa: Phakathi nenqubo yokufafaza, izinga lokushisa eliyisisekelo liphansi, lisusa ukucindezeleka okushisayo kanye nengozi yokuguqulwa nokuqhekeka.

Izinketho Zokuhlanganisa Ezihlukahlukene: I-ceramics ehlukene, ama-alloys, nezinye izinto zingakhethwa ngokusekelwe ezidingweni zohlelo lokusebenza ukuze kuzuzwe ukuthuthukiswa kokusebenza endaweni ye-roller.

Izimo zohlelo lokusebenza: Ilungele kakhulu izinhlelo zokusebenza ezidinga ukuguga okuncane nokukhandwa ngokushesha.

Njengoba zibhekene nobuchwepheshe obuhlukahlukene bokukhanda ama-roller surface, izinkampani kufanele zikhethe kanjani? Lokhu kudinga ukucatshangelwa okuphelele kwalezi zici ezilandelayo:

Gqoka Ubukhulu: Ekugqokeni okukhulu okudinga ukwakheka okubanzi, ukushisela imbondela kuyindlela ekhethwayo; ngokugqoka okuncane okudinga ukulungiswa ngokushesha, ukufuthwa okushisayo kungacatshangwa.

Isabelomali kanye Nomugqa Wesikhathi: Nakuba ukulungiswa kokushisela imbondela kuthatha isikhathi eside, kunikeza ukuqina okukhulu futhi kubiza kakhulu ngokuhamba kwesikhathi.

Umhlinzeki Wesevisi Yokulungisa: Kubalulekile ukukhetha inkampani yokulungisa isigayo esinemishini yobuchwepheshe nolwazi olubanzi. Leli thimba lochwepheshe lingaqinisekisa ikhwalithi yokulungisa futhi linikeze ukwesekwa kwezobuchwepheshe okuphelele.

Isifinyezo: Ubuchwepheshe bokulungisa i-high-pressure roller mill roller buyingxenye ebalulekile ekuqinisekiseni ukusebenza kahle kwemishini futhi ezinzile. Ukushisela imbondela yochwepheshe noma ukufutha okushisayo kungabhekana ngokuphumelelayo nokuguga kwama-roller, kunwebe ukuphila kwemishini, futhi kunciphise kakhulu izindleko zokusebenza.

Uma uhlangabezana nokuguga kwamarola kumaroli akho anomfutho ophezulu wokugaya noma ufuna izinsiza zokukhanda amarola, sincoma ukuthi uxhumane nomhlinzeki wesevisi yokulungisa ochwepheshe ukuze uthole izixazululo ezenziwe ngokwezifiso.

Add: I-Luoxin Industrial Zone, Idolobha laseLuoyang, Isifundazwe saseHenan P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com

Amptelike agent van ZY MINING in Rusland.

Skryf asseblief hier in.

Add: I-Luoxin Industrial Zone, Idolobha laseLuoyang, Isifundazwe saseHenan P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com