-

Products

-

Application

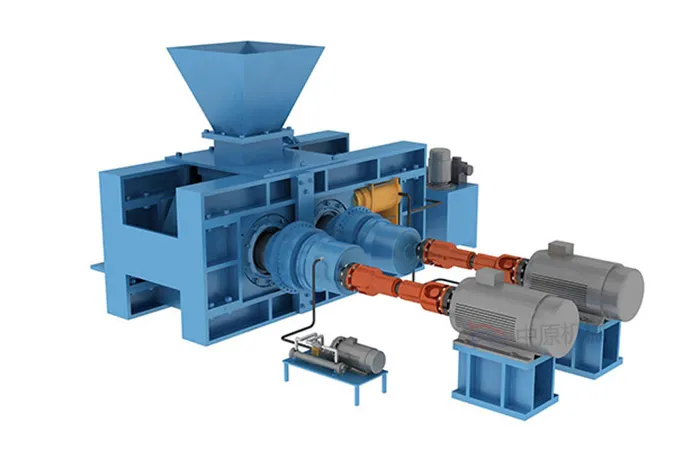

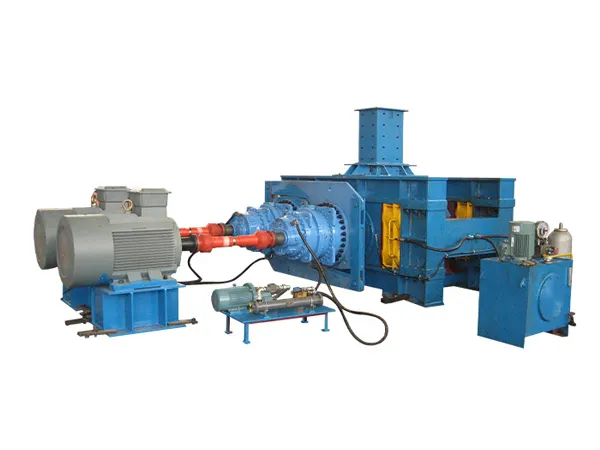

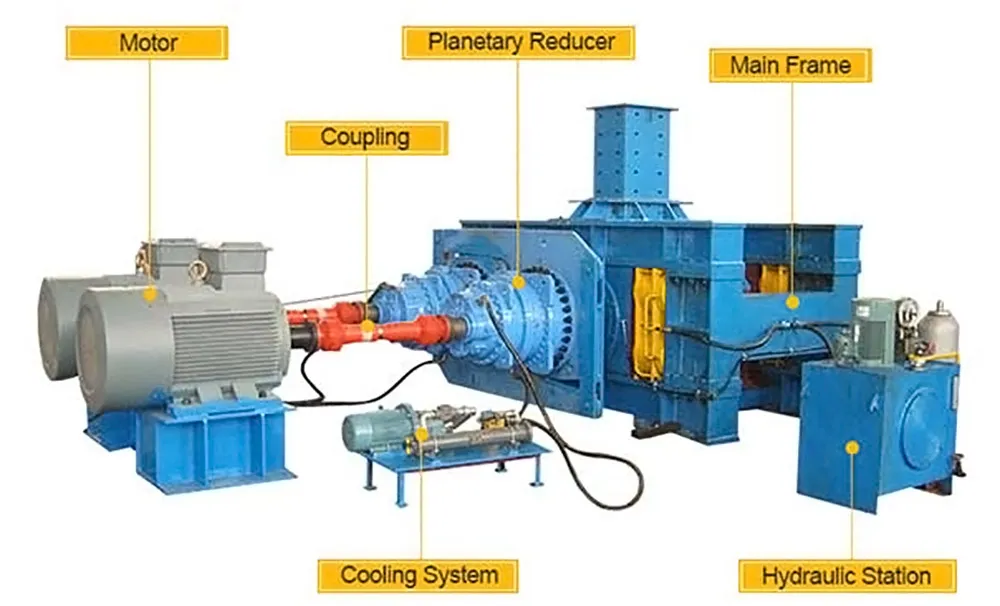

High-pressure grinding rolls (HPGRs), core grinding equipment in industries such as cement, mining, and metallurgy, are critical components that bear immense pressure. However, under long-term, high-load operation, HPGR roller surface wear is an unavoidable problem. Wear not only reduces production efficiency and increases energy consumption, but can also cause downtime and significant economic losses. Effective and cost-effective roller surface repair has become a key concern within the industry.

This article provides an in-depth analysis of HPGR roller surface repair technologies, helping you select the most appropriate solution to extend equipment life and improve production efficiency.

Understanding Roller Surface Wear: Why Repair Is Necessary?

During operation, materials in a HPGR are subjected to intense compression and shearing between two counter-rotating rollers. This constant friction and impact gradually develops pits, grooves, and cracks on the roller surface. If not addressed promptly, wear will worsen, affecting material pulverization efficiency and potentially leading to roller surface spalling and serious damage to the equipment.

Roller surface repair is more than just a simple "patch." It involves restoring the roller surface's original dimensions and wear-resistant properties through specialized processes and wear-resistant materials, enabling continued efficient and stable operation.

Currently, the mainstream high-pressure grinding roller (HPGR) roller surface repair technologies on the market are the following:

Hardfacing repair is the most widely used and proven roller surface repair method. Using a heat source such as an arc or plasma, specially formulated wear-resistant alloy wire or powder is deposited onto the worn roller surface, forming a new, highly wear-resistant layer.

Technical Advantages:

High Wear Resistance: Using HPGR wear-resistant materials such as high-chromium cast iron and high-carbon, high-alloy steel, the repaired roller surface exhibits high hardness and wear resistance, extending its service life far beyond the original roller surface.

High Repair Precision: Using CNC hardfacing repair equipment, the thickness and shape of the weld layer can be precisely controlled to ensure roller surface flatness.

Cost-Effectiveness: Compared to replacing a complete set of rollers, overlay repairs are more cost-effective and require shorter turnaround times, significantly reducing downtime and maintenance costs.

Process Flow:

Pretreatment: Clean, degrease, and preheat the worn roller surface.

Overlay: Use automated overlay equipment to perform multiple layers of overlay.

Finishing: The overlayed roller surface undergoes finishing operations such as turning and grinding to achieve the desired dimensions and surface finish.

Inspection: Non-destructive testing is performed on the repaired roller surface to ensure repair quality.

Thermal spray repair involves heating a wear-resistant material in powder or wire form to a molten or semi-molten state using a flame, arc, or plasma method. The material is then sprayed onto the roller surface at high speed, forming a dense coating.

Technical Advantages:

Fast Repair Speed: The thermal spray process is relatively simple, and the repair turnaround time is short.

No Heat-Affected Zone: During the spraying process, the base material temperature is low, eliminating thermal stress and the risk of deformation and cracking.

Diverse Coating Options: Different ceramics, alloys, and other materials can be selected based on the application requirements to achieve functional upgrades to the roller surface.

Application Scenarios: Primarily suitable for applications requiring minimal wear and rapid repair.

Faceted with a variety of roller surface repair technologies, how should companies choose? This requires comprehensive consideration of the following factors:

Wear Severity: For severe wear requiring extensive buildup, overlay welding is the preferred method; for minor wear requiring rapid repair, thermal spraying can be considered.

Budget and Timeline: Although overlay welding repairs take a slightly longer time, they offer greater durability and are more cost-effective in the long term.

Repair Service Provider: It is crucial to select a roller mill repair company with professional equipment and extensive experience. This professional team can ensure repair quality and provide comprehensive technical support.

Summary: High-pressure roller mill roller surface repair technology is a key component in ensuring efficient and stable equipment operation. Professional overlay welding or thermal spraying can effectively address roller wear, extend equipment life, and significantly reduce operating costs.

If you're experiencing roller wear on your high-pressure grinding rolls or are looking for professional roller repair services, we recommend contacting a professional repair service provider for customized solutions.

Add: Luoxin Industrial Zone,Luoyang City,Henan Province P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com

Official Agent of ZY MINING in Russia.

Please enter here.

Add: Luoxin Industrial Zone,Luoyang City,Henan Province P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com