-

Products

-

Application

HPGRs improve grinding efficiency primarily through a fundamentally different and more energy-efficient breakage mechanism called inter-particle comminution. This process not only consumes significantly less energy (20-50% less) than traditional grinding mills but also induces micro-cracks in the particles, making subsequent grinding stages easier and improving mineral liberation, which boosts overall plant throughput and metallurgical recovery.

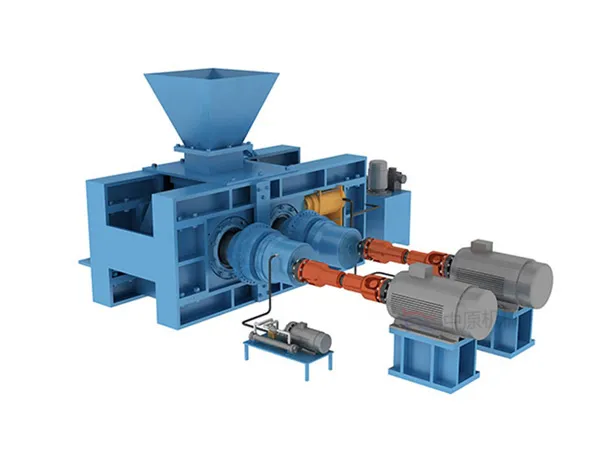

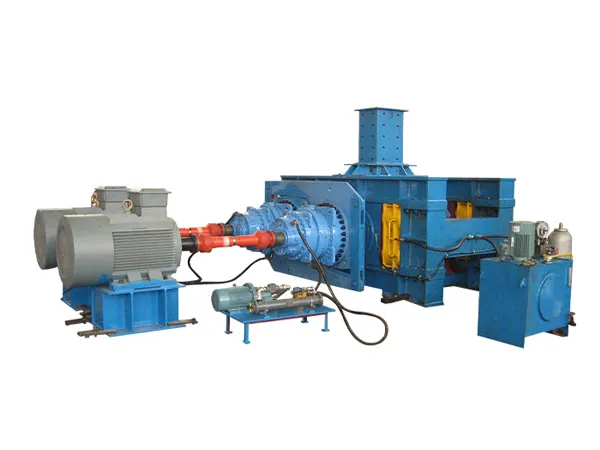

1. The Core Mechanism: How an HPGR Works

To understand its efficiency, you first need to understand how it works, which is very different from a conventional SAG or Ball Mill.

Feed Introduction: Material (ore) is choke-fed from a hopper into the gap between two large, counter-rotating rolls.

High-Pressure Zone: One roll is fixed, while the other is on a hydraulic system that allows it to move, applying immense pressure (typically >100 MPa) to the material.

Particle Bed Compression: As the material is drawn into the gap, it forms a compressed "bed." The key is that the pressure is not applied to individual particles against a steel surface. Instead, the force is transmitted through the bed of particles.

Inter-Particle Comminution: This is the secret to the HPGR's success. The intense pressure causes particles to crush against each other. Rock-on-rock grinding is far more energy-efficient than the rock-on-steel impact and attrition that happens in a ball mill.

Discharge: The material exits the rolls as a compacted, brittle "cake" or "flake," which is then de-agglomerated before moving to the next stage.

2. Key Ways HPGR Improves Grinding Efficiency

The efficiency gains from this mechanism can be broken down into several key areas.

a) Superior Energy Efficiency (The Primary Benefit)

This is the most significant advantage. Grinding is the most energy-intensive process in most mining operations.

Direct Force Application: In a ball mill, a huge amount of energy is wasted simply lifting thousands of tons of steel balls and slurry, with much of the energy lost as heat and noise upon impact. In an HPGR, nearly all the energy from the motors and hydraulic system is applied directly to the particle bed for breakage.

Efficient Breakage Mode: Inter-particle comminution is inherently more efficient. It exploits the weakest points in the rock structure, requiring less energy to achieve the same size reduction.

Result: HPGR circuits can consume 20-50% less energy (measured in kWh/ton) than a traditional SAG/Ball Mill circuit to achieve the same final product size.

b) Generation of Micro-Cracks (Improved Grindability)

The intense pressure doesn't just break particles; it creates a high density of micro-cracks and fractures within particles that don't fully break.

Weakened Feed: This "pre-weakened" material is fed to the next grinding stage (often a ball mill).

Easier Downstream Grinding: The ball mill now has a much easier job. It requires less impact energy and less time to break these pre-fractured particles down to the final target size.

Result: This effect is a major contributor to increased throughput for the entire grinding circuit. A ball mill that previously processed 1000 tons per hour might now process 1200-1400 tons per hour of HPGR product to achieve the same grind.

c) Preferential Liberation of Minerals

The pressure in an HPGR tends to break particles along their natural grain boundaries—the interface between the valuable mineral (e.g., copper, gold) and the waste rock (gangue).

Traditional Grinding: Impact grinding in a ball mill is more random. It can shatter particles right through the valuable mineral grains, sometimes locking fine mineral particles within larger gangue particles.

HPGR Grinding: By breaking along boundaries, the HPGR "liberates" the valuable mineral more cleanly.

Result: This leads to improved metallurgical performance. Better liberation means higher recovery rates in downstream processes like flotation or leaching, as the target mineral is more exposed to the chemical reagents.

d) Reduced Consumption of Grinding Media and Liners

No Grinding Media: HPGRs do not use steel balls, which are a major operational cost (consumable) for ball mills.

Lower Liner Wear: While the HPGR rolls themselves wear down and require expensive replacement or re-surfacing, the overall wear cost per ton is often lower than the combined cost of liners and grinding media in a traditional mill. The particle bed itself forms an "autogenous" protective layer on the roll surface, reducing direct wear.

e) Flexibility in Operation (Wet or Dry)

HPGRs can operate completely dry. This is a massive advantage in arid, water-scarce regions where sourcing water for a traditional wet grinding circuit is prohibitively expensive or environmentally damaging.

This also eliminates the need for expensive dewatering equipment in some circuit designs.

|

High-Pressure Grinding Roll (HPGR) |

Traditional Ball/SAG Mill |

|

|

Grinding Mechanism |

Inter-particle comminution (rock-on-rock under high pressure). |

Impact and attrition (rock-on-steel, rock-on-rock). |

|

|

Energy Consumption |

Very High Efficiency. (20-50% lower kWh/t). |

Lower Efficiency. High energy loss in lifting media. |

|

|

Micro-Crack Formation |

High. Significantly weakens particles for downstream processing. |

Low. Breakage is more random and complete. |

|

|

Mineral Liberation |

Excellent/Preferential. Breaks along grain boundaries. |

Good/Random. Can trap minerals within gangue. |

|

|

Grinding Media |

None. |

Significant consumption of steel balls. |

|

|

Water Usage |

Can operate completely dry. |

Requires water to form a slurry. |

|

|

Throughput Impact |

Increases circuit throughput by preparing feed for other mills. |

Is the bottleneck in many conventional circuits. |

|

|

Feed Size |

Typically a tertiary or quaternary crushing stage. |

SAG mills can take very coarse primary-crushed feed. |

|

|

Product |

Compacted "cake" with a wide size distribution. |

Slurry with a more defined size distribution. |

HPGR equipment improves grinding efficiency not just by being a better "crusher," but by fundamentally changing the properties of the ore. By using the highly efficient method of inter-particle comminution, it slashes energy costs, increases the capacity of the entire plant by making downstream work easier, and improves the final recovery of valuable minerals, providing a multi-faceted improvement to the entire comminution circuit.

Add: Luoxin Industrial Zone,Luoyang City,Henan Province P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com

Official Agent of ZY MINING in Russia.

Please enter here.

Add: Luoxin Industrial Zone,Luoyang City,Henan Province P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com