-

Produkte

-

Toepassing

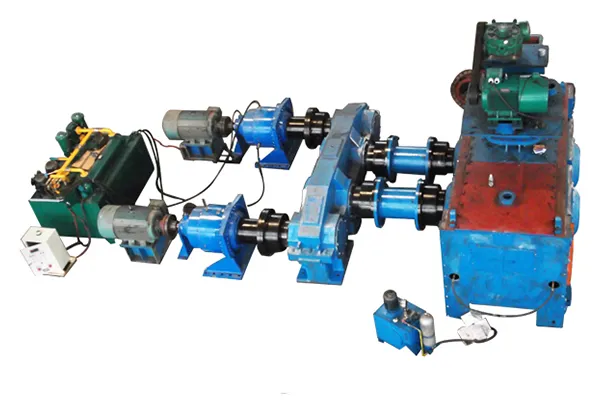

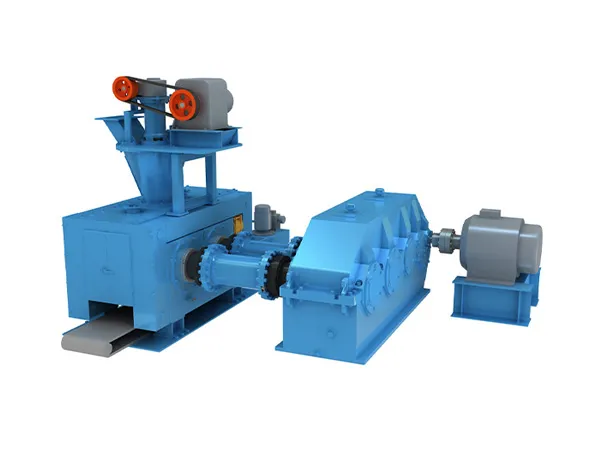

Umshini wokuhlanganisa uklanyelwe ukucindezela izinto ezingavuthiwe zibe amabrikhethi aqinile anomthamo omkhulu nokuqina. Kodwa-ke, ekukhiqizeni kwangempela, abasebenzisi abaningi bathola ukuthi ama-briquette awaqinile ngokwanele, ahlukana kalula phakathi nokuphathwa, ukugcinwa, noma ukuthuthwa. Le nkinga ayigcini nje ukunciphisa ikhwalithi yomkhiqizo kodwa futhi yandisa ukulahlekelwa kwezinto ezibonakalayo kanye nezindleko zokusebenza.

Uma ama-briquette ehlukana kalula, cishe kuhlale kuyinkinga ngeyodwa yezindawo ezintathu ezibalulekile: impahla eluhlaza, isimo/izilungiselelo zomshini, noma inqubo yokusebenza.

A. Izinkinga Zezinto Ezingavuthiwe ("Izithako")

Lokhu kuyimbangela evame kakhulu yama-briquette abuthakathaka.

Okuqukethwe Komswakama Okungalungile: Lesi isigebengu #1.

Okumanzi Kakhulu (>12-15%): Umswakama owedlulele uphenduka ube isitimu ngaphakathi kwedayizi. Lesi sitimu sidala umfutho ophezulu, ongabangela imifantu noma ngisho nokuqhuma okuncane ku-briquette njengoba uphuma emshinini. I-briquette yokugcina izoba buthakathaka futhi ibe nobuso obuqinile, obuphukile.

Kome Kakhulu (<6-8%): Okubalulekile ngeke kugeleze noma kuhlangane kahle. I-Lignin (i-binder yemvelo ku-biomass) idinga inani elincane lomswakama ukuze ipulasitiki futhi ibophe ngempumelelo. Impahla eyome ngokweqile ibangela ibriquette eshwabene, eyakheke kabi.

I-Ideal Range: Eningini le-biomass (njenge-sawdust), okuqukethwe komswakamo okufanelekile kungu-8% kuya ku-12%.

Usayizi Wezinhlayiyana Ongalungile:

Okukhulu Kakhulu: Izinhlayiya ezinkulu zenza ama-void (amaphakethe omoya) ngaphakathi kwe-briquette, okuholela emaphuzwini abuthakathaka. Awahlangani ngendlela efanayo, okuholela kumkhiqizo ophuka kalula.

I-Too Fine (njengothuli): Nakuba ingcono kunenkulu kakhulu, impushana ecoleke ngokwedlulele ngezinye izikhathi ingase ibambe umoya futhi ingase idinge ukucindezela okuphezulu noma izilinganiso ezithile zokuhlanganisa ukuze zakhe i-briquette eqinile.

Usayizi Ofanelekile: Ngokuvamile, izinhlayiya kufanele zibe ngaphansi kuka-5-6 mm zokucindezela kohlobo lwesikulufu. Ukungaguquguquki, usayizi ofanayo ubalulekile.

Okuqukethwe kwe-Lignin ephansi noma ukushoda kwe-binder:

I-Lignin iyi-polymer yemvelo okhunini kanye ne-biomass encibilika ngaphansi kokushisa okuphezulu nokucindezela, isebenza njengeglue yemvelo. Izinto ezifana ne-sawdust zicebile nge-lignin.

Izinto ezine-lignin ephansi (isb., amakhoba elayisi, obunye utshani) noma izinto ezingezona ze-biomass (isb., uthuli lwamalahle, impushana yamalahle) ngeke zizibophe kahle ngokwazo. Zidinga isibopho sangaphandle (njengesitashi, i-molasses, noma ubumba) ukuze kuxutshwe kuso.

Ubumsulwa Bezinto:

Ukungcola okufana nesihlabathi, inhlabathi, amatshe, noma insimbi kuzophazamisa inqubo yokuhlanganisa, kudale izindawo ezibuthakathaka, futhi kulimaze kabi izingxenye zomshini (ikakhulukazi isikulufu nokufa).

B. Izinkinga Ezihlobene Nomshini ("Izisetshenziswa")

Uma impahla yakho iphelele, inkinga ilele emshinini ngokwawo.

Izinga lokushisa elingalungile:

Phansi Kakhulu: Uma amakholomu okushisisa kudayizi engashisi ngokwanele, i-lignin ku-biomass ngeke incibilike kahle. Ngaphandle kokuthi le "glue" icushwe, i-briquette izokhululeka futhi ihlakazeke.

Iphezulu Kakhulu: Ukushisa okudlulele kungashisa noma kushise okokusebenza. Impahla eshile ishwabene futhi ayinawo amandla okubopha. Kungase futhi kuholele ekwakhekeni kwekhabhoni ngaphakathi kwefa, kubangele ukuvinjelwa.

Izinga Lokushisa Elifanelekile: Lokhu kuyahlukahluka ngokokusebenza, kodwa kuvame ukuba ku-280°C kuya ku-380°C (530°F kuya ku-715°F).

Ingcindezi Enganele:

Inhloso yonke yomshini ukufaka ingcindezi enkulu. Uma ingcindezi iphansi kakhulu, izinhlayiya ngeke ziphoqwe ndawonye ziqine ngokwanele ukuze zihlangane. Lokhu kuvame ukubangelwa izingxenye ezigugile.

Izingxenye Ezigugile:

I-Screw Propeller (I-Auger): Lena ingxenye eyinhloko yokugqokwa. Njengoba isebenza, imiphetho yayo iyawohloka. Isikulufu esigugile asikwazi ukusunduza okubalulekile phambili ngamandla anele, sehlisa kakhulu ingcindezi ngaphakathi kwedayizi.

Ukwakha i-Die/Mold: Ingaphakathi le-die libuye ligqoke ngokuhamba kwesikhathi, ikakhulukazi ingxenye eqoshiwe. Lokhu kwandisa ububanzi bangaphakathi, okwehlisa isilinganiso sokuhlanganisa futhi kubangele ibriquette encane, ebuthakathaka.

C. Izinkinga Zokusebenza (I-"Technique")

Kwesinye isikhathi impahla nomshini kulungile, kodwa indlela okusetshenziswa ngayo ayilungile.

Isilinganiso Sokudla Esingahambisani:

Ukondla Ngokushesha Kakhulu: Ukulayisha umshini ngokweqile kuvimbela okokusebenza ekuchitheni isikhathi esanele endaweni yokushisisa ukuze kufinyelele izinga lokushisa elilungile. Lokhu kuholela ekusebenzeni kabi kwe-lignin kanye nokuvinjwa okungenzeka.

Ukondla Kakhulu Kakhulu: Ukunikezwa okunganele kwezinto kusho ukuthi isikulufu asikwazi ukwakha ingcindezi engemuva edingekayo ukuze kuhlangane kahle.

Ukuqala Okungalungile:

Umshini kufanele uvunyelwe ukuthi ushise ngaphambili kuze kufike ezingeni lokushisa eliqondiwe ngaphambi kokuphakela noma iyiphi impahla. Ukuphakela emshinini obandayo kuzohlale kukhiqiza ama-briquette asezingeni eliphansi futhi kungabangela ujamu.

Ukupholisa Okusheshayo:

Ama-briquette ashisa kakhulu futhi angaphansi kwengcindezi yangaphakathi lapho ephuma kufa. Uma zipholiswe ngokushesha kakhulu (isb., ngesiphephetha-moya noma ngamanzi), zingahlakulela imifantu yokucindezeleka okushisayo, kuzenze zibe brittle. Kufanele bavunyelwe ukuba baphole kancane kancane.

Uma inkinga ingokusebenza komshini noma ubuqotho besakhiwo, nazi izimbangela ezingaba khona:

Izinkinga zokuhlinzeka ngezimoto namandla:

I-Underpowered Motor: Kungenzeka ukuthi umshini wakhiwe ngenjini encane kakhulu kuhlobo noma umthamo wezinto ezicutshungulwayo.

I-Voltage Drop: I-voltage engazinzile noma ephansi evela kugesi wakho izobangela ukuthi injini ilahlekelwe i-torque, okuholela ekumeni ngaphansi komthwalo.

Amabhande/Amagiya Agugile: Ukushibilika kwamabhande e-V noma amagiya agugile ku-gearbox kusho ukuthi amandla enjini awadluliswa ngendlela eyisikulufu.

Ukuvinjwa Kwemishini:

Into yangaphandle (insimbi, itshe) noma impahla emanzi kakhulu/enkulu idale ukujamu ngaphakathi komgqomo noma ife, okubangele umshini ukuthi umise noma ukhube ukuvikela kwawo ukulayisha ngokweqile.

Ikhwalithi Yokwakha Engalungile:

Uhlaka lomshini lwenziwe ngensimbi encane noma lunamashisela abuthakathaka angaqhekeka noma agobe ngaphansi kwengcindezi enkulu kanye nokudlidliza okuqhubekayo kokusebenza.

Ukuntuleka Kwesondlo:

Ukwehluleka ukugcoba ama-bearings nama-gearbox kubangela ukungqubuzana nokushisa okudlulele, okuholela ekuhlulekeni ngaphambi kwesikhathi nokuphelelwa amandla.

Amabhawodi axegayo kanye nezibophelelo kungabangela ukungaqondani kahle nokucindezeleka kwesakhiwo.

Qala ngezinkinga ezilula nezijwayelekile kuqala:

✅ Hlola Umswakama: Sebenzisa imitha yomswakama. Ingabe impahla yakho eluhlaza iphakathi kuka-8-12%?

✅ Hlola Izinga Lokushisa: Ingabe umshini ushise ngokuphelele ngaphambi kwezinga lokushisa elinconyiwe lempahla yakho?

✅ Hlola Ukubukeka KweBriquette: Ingabe inendawo ebushelelezi, ecwebezelayo (enhle) noma iqhekekile futhi ibuthuntu (embi)?

✅ Hlola usayizi we-particle: Ingabe impahla igaywe ngokulinganayo ibe usayizi ofanele?

✅ Qaphela Izinga Lokusuthisa: Ingabe uwuphakela umshini ngezinga elizinzile, elingaguquki?

✅ Hlola I-Wear Parts: Ugcine nini ukuhlola noma ukufaka esikhundleni sophephela oyisikulufa kanye nedayizi? Uma ukhiqize amathani amaningi ama-briquette, lezi zingxenye cishe zigqokile.

Umshini wokuhlanganisa ukhiqiza ama-briquette abuthakathaka lapho izici ezibalulekile njengezakhiwo zempahla eluhlaza, isimo somshini, nezilungiselelo zokusebenza zingaqondani kahle.

Ukuqonda izizathu zamandla e-briquette abuthakathaka kubalulekile ekuthuthukiseni ukusebenza komshini kanye nokuqinisekisa ukukhiqizwa okuphumelelayo.Izici ezivamile zihlanganisa umswakama wempahla eluhlaza ongafanele, ingcindezi enganele, ukukhetha okubi kwe-binder, ukuguga kwezingxenye zomshini, nemingcele yokusebenza engalungile.

Add: I-Luoxin Industrial Zone, Idolobha laseLuoyang, Isifundazwe saseHenan P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com

Amptelike agent van ZY MINING in Rusland.

Skryf asseblief hier in.

Add: I-Luoxin Industrial Zone, Idolobha laseLuoyang, Isifundazwe saseHenan P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com