-

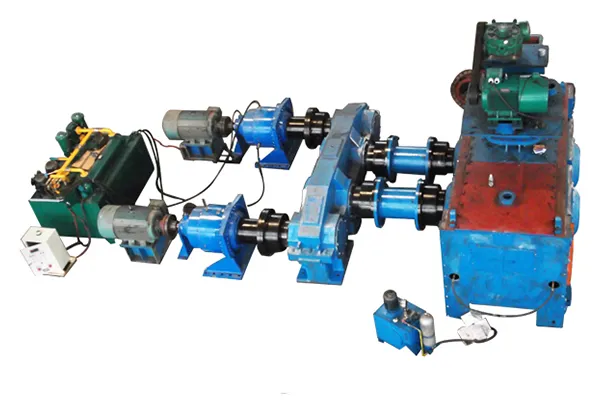

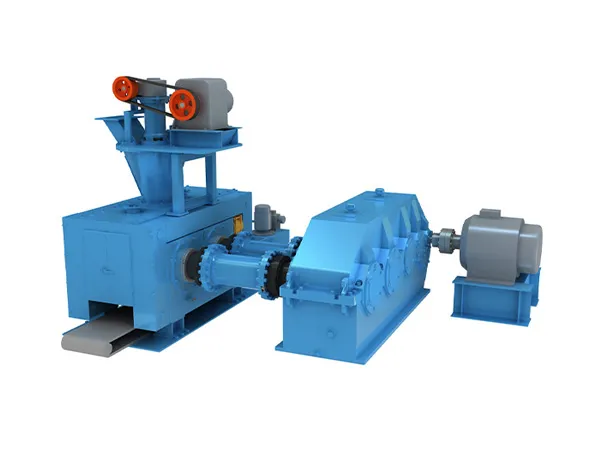

Products

-

Application

A briquetting machine is designed to compress raw materials into solid briquettes with high density and durability. However, in actual production, many users find that the briquettes are not strong enough, easily breaking apart during handling, storage,or transportation. This problem not only reduces product quality but also increases material loss and operational costs.

When briquettes fall apart easily, it's almost always a problem with one of three key areas: the raw material, the machine's condition/settings, or the operating procedure.

A. Raw Material Issues (The "Ingredients")

This is the most frequent cause of weak briquettes.

Incorrect Moisture Content: This is the #1 culprit.

Too Wet (>12-15%): Excess moisture turns into steam inside the die. This steam creates high pressure, which can cause cracks or even small explosions in the briquette as it exits the machine. The final briquette will be weak and have a rough, fractured surface.

Too Dry (<6-8%): The material won't flow or compact properly. Lignin (the natural binder in biomass) requires a small amount of moisture to plasticize and bind effectively. Overly dry material results in a crumbly, poorly formed briquette.

Ideal Range: For most biomass (like sawdust), the ideal moisture content is 8% to 12%.

Improper Particle Size:

Too Large: Large particles create voids (air pockets) within the briquette, leading to weak points. They don't compact uniformly, resulting in a product that easily breaks.

Too Fine (like dust): While better than too large, extremely fine powder can sometimes trap air and may require higher pressure or specific binder ratios to form a strong briquette.

Ideal Size: Generally, particles should be under 5-6 mm for screw-type presses. A consistent, uniform size is key.

Low Lignin Content or Lack of Binder:

Lignin is a natural polymer in wood and biomass that melts under high heat and pressure, acting as a natural glue. Materials like sawdust are rich in lignin.

Materials with low lignin (e.g., rice husks, some grasses) or non-biomass materials (e.g., coal dust, charcoal powder) won't bind well on their own. They require an external binder (like starch, molasses, or clay) to be mixed in.

Material Purity:

Contaminants like sand, soil, stones, or metal will disrupt the compaction process, create weak spots, and severely damage the machine's components (especially the screw and die).

B. Machine-Related Issues (The "Equipment")

If your material is perfect, the problem lies with the machine itself.

Incorrect Temperature:

Too Low: If the heating collars on the die are not hot enough, the lignin in the biomass won't melt properly. Without this "glue" being activated, the briquette will be loose and crumbly.

Too High: Excessive heat can char or burn the material. Burnt material is brittle and has no binding strength. It can also lead to a buildup of carbon on the inside of the die, causing blockages.

Ideal Temperature: This varies by material, but is often in the 280°C to 380°C (530°F to 715°F) range.

Insufficient Pressure:

The entire purpose of the machine is to apply immense pressure. If the pressure is too low, the particles won't be forced together tightly enough to bond. This is often caused by worn-out parts.

Worn-Out Components:

Screw Propeller (Auger): This is the main wear part. As it operates, its edges wear down. A worn screw cannot push material forward with enough force, drastically reducing the pressure inside the die.

Forming Die/Mold: The inside of the die also wears over time, especially the tapered section. This increases the internal diameter, which lowers the compaction ratio and results in a less dense, weaker briquette.

C. Operational Issues (The "Technique")

Sometimes the material and machine are fine, but the way they are being used is wrong.

Inconsistent Feeding Rate:

Feeding Too Fast: Overloading the machine prevents the material from spending enough time in the heating zone to reach the correct temperature. This leads to poor lignin activation and potential blockages.

Feeding Too Slow: An insufficient supply of material means the screw can't build up the necessary back-pressure for proper compaction.

Improper Start-up:

The machine must be allowed to pre-heat to the target temperature before feeding any material. Feeding into a cold machine will always produce poor-quality briquettes and can cause a jam.

Rapid Cooling:

Briquettes are extremely hot and under internal stress when they exit the die. If they are cooled too quickly (e.g., by a fan or water), they can develop thermal stress cracks, making them brittle. They should be allowed to cool gradually.

If the issue is with the machine's performance or structural integrity, here are the likely causes:

Motor and Power Supply Issues:

Underpowered Motor: The machine may have been built with a motor that is too small for the type or volume of material being processed.

Voltage Drop: Unstable or low voltage from your electrical supply will cause the motor to lose torque, leading to stalling under load.

Worn Belts/Gears: Slipping V-belts or worn-out gears in the gearbox mean the motor's power isn't being transferred effectively to the screw.

Mechanical Blockage:

A foreign object (metal, stone) or overly wet/large material has created a jam inside the barrel or die, causing the machine to stall or trip its overload protection.

Poor Build Quality:

The machine's frame is made from thin steel or has weak welds that can crack or bend under the immense pressure and constant vibration of operation.

Lack of Maintenance:

Failure to lubricate bearings and gearboxes causes excessive friction and heat, leading to premature failure and power loss.

Loose bolts and fasteners can cause misalignment and structural stress.

Start with the easiest and most common issues first:

✅ Check Moisture: Use a moisture meter. Is your raw material between 8-12%?

✅ Check Temperature: Is the machine fully pre-heated to the recommended temperature for your material?

✅ Inspect Briquette Appearance: Does it have a smooth, slightly shiny surface (good) or is it cracked and dull (bad)?

✅ Check Particle Size: Is the material uniformly ground to the correct size?

✅ Observe Feeding Rate: Are you feeding the machine at a steady, consistent pace?

✅ Inspect Wear Parts: When was the last time you checked or replaced the screw propeller and the die? If you've produced many tons of briquettes, these parts are likely worn.

A briquetting machine produces weak briquettes when key factors like the raw material's properties, the machine's condition, and operational settings are not properly aligned.

Understanding the reasons behind weak briquette strength is essential for improving machine performance and ensuring efficient production.Common factors include inappropriate raw material moisture, insufficient pressure, poor binder selection, wear of machine components, and incorrect operating parameters.

Add: Luoxin Industrial Zone,Luoyang City,Henan Province P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com

Official Agent of ZY MINING in Russia.

Please enter here.

Add: Luoxin Industrial Zone,Luoyang City,Henan Province P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com