-

Products

-

Application

High pressure grinding rolls is a kind of crushing and grinding equipment that fully crushes materials by using the principle of static pressure crushing. Through the opposite movement of different rollers, the materials can be fully squeezed, and according to the properties of different ore, different roller surfaces can be used. and operating pressure, so it is often used in various mineral processing projects. The following high-pressure roller mill manufacturers will introduce several applications of high-pressure roller mills in mineral processing, hoping to help you better understand high-pressure roller mills. .

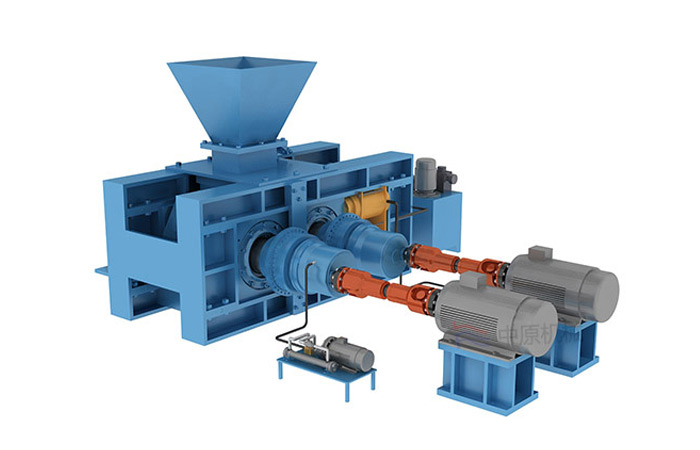

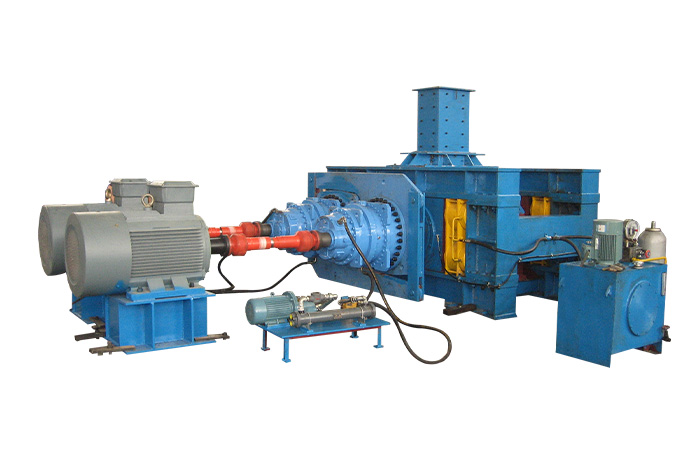

The pressure device and transmission device of high pressure grinding rolls mainly include frame, high pressure roller and so on. The high pressure grinding rollscan generate different pressures according to the different characteristics of the material, and the surface is equipped with a wear-resistant plate, and the hydraulic cylinder can move the adjusting roller along the guide groove during the pressing process. Driven by the drive gear reducer, the material is replenished in time between the rollers, and a dense cake-shaped block can be generated under high pressure. In order to ensure that the crushing area has good high pressure conditions, it is necessary to configure a pressing device according to the production and processing requirements, and then it is necessary to select wear-resistant materials with higher strength values.

1. Diamond ore dissociation and crushing

The high pressure grinding rolls was used earlier in the dissociation and crushing of diamond ore. Various data show that the high pressure grinding rolls can obtain finer pulverized products at a larger roller spacing, and a larger roller spacing can avoid damage to high-value large-particle diamonds during the pulverization process.

2. Application in iron ore processing

In the actual field of iron ore processing, the main role of the high pressure grinding rolls is the pretreatment and fine or ultra-fine crushing of ore materials, as well as the pretreatment of iron ore concentrate pellets. At present, the use of high pressure grinding rolls instead of ball mills or in conjunction with ball mills as pre-grinding equipment for iron ore concentrate pellets has been widely accepted. This treatment method can improve the performance of the ball and improve the quality of the green ball. Even in the pellet mill, the high pressure grinding rolls can not only undertake the task of improving the fineness and specific surface area of the iron concentrate, but also can be placed before the ball mill. , to improve the fineness of the ball mill feed and the processing capacity of the entire system.

3. Non-ferrous and precious metal ore crushing

When the high pressure grinding rolls was used to treat non-ferrous metal ore in the early days, although the pulverization effect and the impact on the subsequent operation indicators were good, and the operation rate reached an acceptable range after continuous optimization in various aspects, the roller surface wear problem was very serious. severe. With the continuous improvement of stud roller surface technology in recent years and the research on multi-stage processing technology, the use of multiple high pressure grinding rolls for multi-stage processing has become the main processing technology for many non-ferrous and precious metal ores.

1. According to the processing requirements, the high pressure grinding rolls needs to be replaced after a period of application, which can effectively improve its work efficiency.

2. In addition to the regular replacement of the roller surface, the use of equipment to effectively smooth the roller surface can effectively control various wear problems on the roller surface.

3. In actual production, it is necessary to take improvement measures for the high pressure grinding rolls based on the processing status to ensure that its operating efficiency can be effectively improved.

Through development so far, the application value of high pressure grinding rolls in mineral processing has been widely recognized, and in addition to mineral processing and production, high pressure grinding rolls have also been introduced for production operations in many fields.

Official Agent of ZY MINING in Russia.

Please enter here.

Add: Luoxin Industrial Zone,Luoyang City,Henan Province P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com