-

Products

-

Application

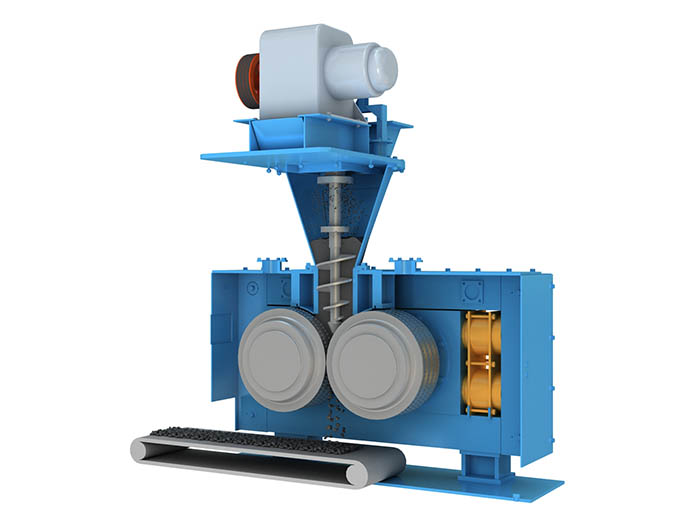

As a molding equipment for pressing various materials, the ball press machine can meet the pressing needs of different industries. However, the selected roller skin does not match the material to be pressed, which can easily cause the wear of the ball skin of the ball press. The degree of wear caused by different hardness is also different, so the selection of the material of the roller skin of the ball press is very important. So what are the materials of roller skins on the market? Which one is more wear-resistant?

The materials of common roller skins are divided into cast spring steel, alloy steel, bearing steel, etc. For different materials, the roller skins are different, and they all have their own advantages.

Cast spring steel has high hardenability, surface decarburization tendency is smaller than silicon steel, and its comprehensive mechanical properties are better than carbon steel after heat treatment. It has very good fatigue strength, excellent elasticity, and good plasticity and hardness. At the same time, the low price makes it more popular, but it has overheat sensitivity and tempering brittleness, so it is usually used on small-volume ball presses, and can press soft materials such as coal powder, coke powder, and charcoal powder.

This alloy steel undergoes strict processing, and its hardness can reach HRC58-62. It has high strength and abrasion resistance, at the same time has certain corrosion resistance, and is easy to detach the ball. This alloy steel roll skin is forged Hitting parts are mainly used on medium and large-scale coal briquette presses, which can compact ore powder, iron fine powder, magnesium oxide, laterite nickel ore, etc.

Compared with alloy steel, bearing steel has higher hardness and wear resistance, but also has uniform hardness, high elastic limit, high contact fatigue strength, necessary toughness, certain hardenability, Corrosion resistance. And as a ball press forging roller skin, it is more wear-resistant than the casting type.

It is not difficult to see that although the cost of the cast roller skin is low and can be replaced frequently after wear, this non-wearable roller skin is only increasing the price of the ball press in disguise. The cost paid by the operator will only change with the use of time. It is gradually improved, and the forged rolls of chromium-molybdenum alloys are more wear-resistant. You only need to pay for one return. The forged rolls of bearing steel have higher performance than chrome-molybdenum alloys, which can meet the long-term Usage requirements.

Official Agent of ZY MINING in Russia.

Please enter here.

Add: Luoxin Industrial Zone,Luoyang City,Henan Province P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com