-

Products

-

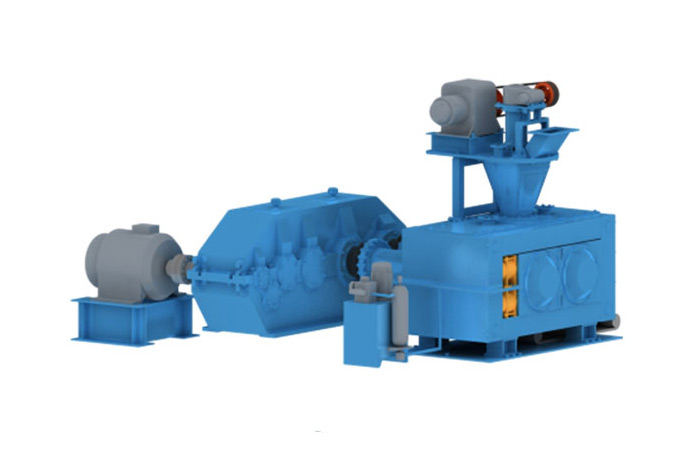

Application

A briquette making machine, also known as a briquette press or briquette maker, is a device used to compress various types of biomass or other materials into uniform, compact briquettes. The price of a briquette making machine can vary widely depending on several factors such as the capacity, power source, automation level, and quality of the machine. Additionally, prices can vary based on the geographical location and the specific manufacturer or supplier.

Manual/Hand-Operated Machines: These machines are small and manually operated, usually producing briquettes on a small scale. Prices for manual briquette making machines can range from $200 to $1,000.

Semi-Automatic Machines: These machines are partially automated and require some manual intervention during the production process. Prices for semi-automatic briquette making machines can range from $1,000 to $5,000.

Fully Automatic Machines: These machines are highly automated, with features such as automatic feeding, compression, and ejection of briquettes. Prices for fully automatic briquette making machines can range from $5,000 to $50,000 or more, depending on the capacity and additional features.

These briquettes can be used as fuel or for other purposes such as cooking, heating, or industrial applications.Here is an overview of the typical process and components involved in a briquette making machine:

Raw Material Preparation

The first step is to prepare the raw materials that will be used to make the briquettes. Common biomass materials include sawdust, wood chips, agricultural residues (such as straw or husks), and various types of biomass waste. The raw materials need to be properly dried to reduce moisture content, which helps in achieving better briquette quality and higher combustion efficiency.

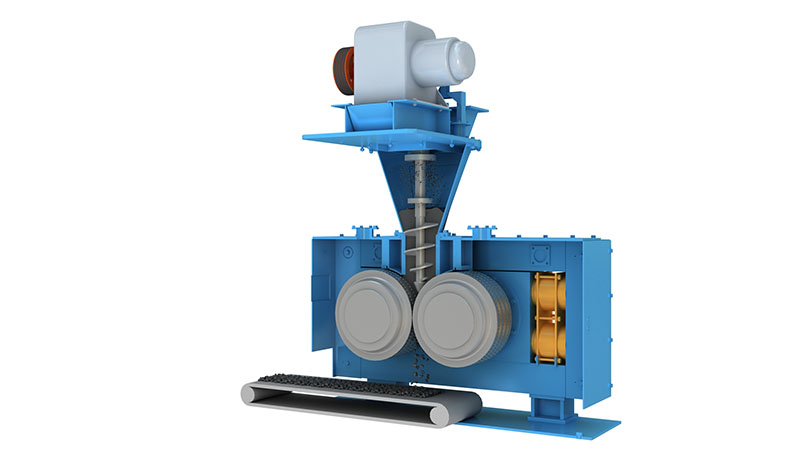

Feeding System

The prepared raw materials are then fed into the briquette making machine using a feeding system. Depending on the design of the machine, this can be done manually or automatically through hoppers, conveyors, or augers. The feeding system ensures a continuous supply of raw materials into the machine for efficient briquette production.

Compression and Extrusion

Inside the briquette making machine, the raw materials are compressed under high pressure. The machine typically consists of a large cylindrical or rectangular chamber with a piston or screw mechanism. As the raw materials pass through the chamber, the pressure generated forces them to bind together and form briquettes. The compression can be achieved through different methods, such as a hydraulic press, mechanical press, or screw extrusion.

Cooling and Solidification

Once the briquettes are formed, they may be hot and fragile. To strengthen and solidify the briquettes, they are usually cooled down. Cooling can be achieved by allowing the briquettes to air-dry naturally or by using cooling systems that involve forced air or water cooling methods.

Briquette Ejection

After cooling, the briquettes are ejected from the briquette making machine. This can be done manually or through an automated ejection system, depending on the machine design. The briquettes are collected and stored for further use or packaging.

It's important to note that the specific design, features, and capacities of briquette making machines can vary significantly depending on the manufacturer and the intended application. Some machines may have additional components or features for specific purposes, such as mixing the raw materials, adjusting the briquette density, or controlling the moisture content.

Add: Luoxin Industrial Zone,Luoyang City,Henan Province P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com

Official Agent of ZY MINING in Russia.

Please enter here.

Add: Luoxin Industrial Zone,Luoyang City,Henan Province P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com