-

Products

-

Application

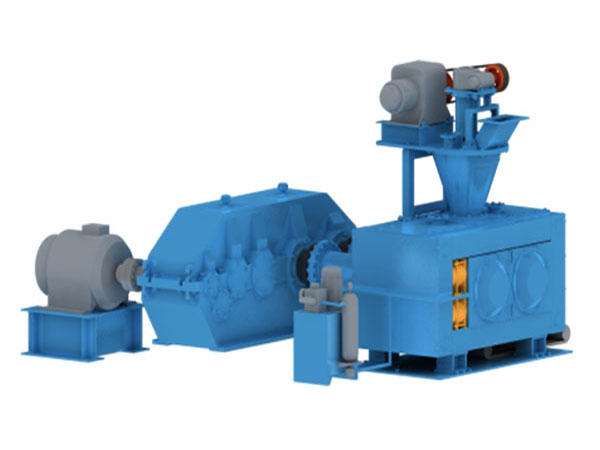

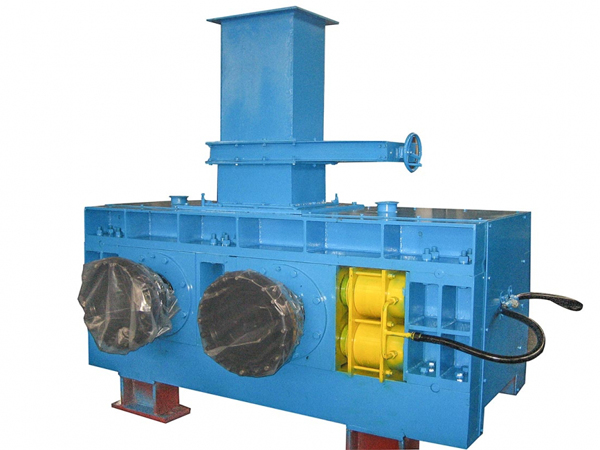

The working environment of the briquetting machine is harsh and the work intensity is high. There are different points of attention for the work of the briquetting machine in different periods. The necessary maintenance and maintenance can extend the use time and life of the briquetting machine. Next, the editor of Luoyang Zhongyuan Mining Machinery will tell you what are the different points of attention in different stages of briquetting machines.

The relevant installation and preparation work must be done before the test machine. Plan ahead and sort out the installation of the machine, preparation of materials, etc. After starting the machine, it must be idling for a few minutes before loading. The significance of this process lies in the preheating of the machine's running-in. And if there is a problem, it can be repaired and solved in advance in time. It will be very troublesome and inconvenient to solve the problem after the material is put into production.

Check whether the circuit is connected properly and whether the raw materials are adequately prepared. In the absence of raw materials, the restricted balls are unstable. Only by ensuring sufficient materials can the restricted balls be robust and not easily broken.

In the production process, the material supply time must be adjusted. If the supply is insufficient, the pressed ball will be unstable, so the decision should be made according to the situation of the ball when the material is supplied. The better strength prevails. If the strength is too small, the strength is not good. If the size is too large, the machine will become too heavy, which will cause the motor to be too heavy, and it is easy to damage the machine or burn the motor. Time to monitor whether the conveyor position is normal. When the conveyor position is not normal, you need to adjust the base support. If there is a deviation, you must correct it in time.

In the briquetting process, there will be a lot of dust and other dirty materials in the briquetting machine. After use, it must be mechanically cleaned. Check whether the machine is faulty, such as whether the screws are loose or not. In many cases, major faults are caused by minor problems. Therefore, we must clean and inspect the equipment after production.

Official Agent of ZY MINING in Russia.

Please enter here.

Add: Luoxin Industrial Zone,Luoyang City,Henan Province P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com