-

Products

-

Application

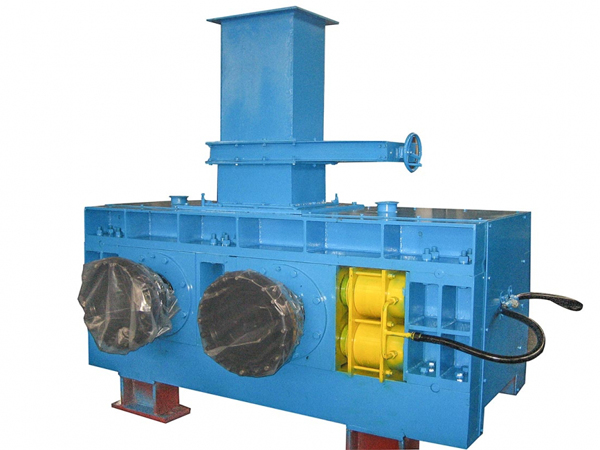

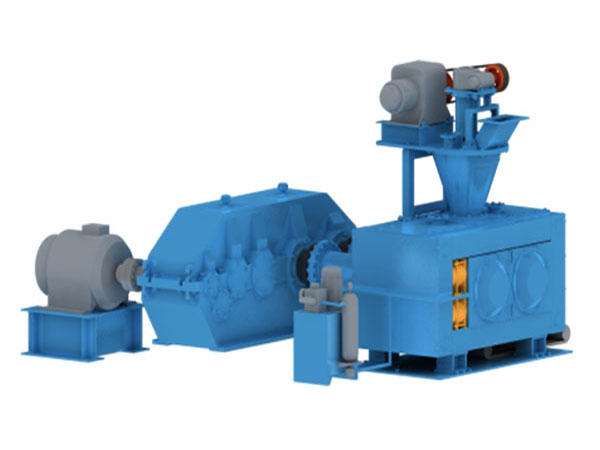

For various coal-related industries and powder processing enterprises, the ball press machine is very familiar, and it should be very clear. The entire material forming production line can be collectively referred to as the ball press production line, because the core of the entire material forming The equipment is a ball press.

When using the briquetting machine production line for material processing, the unavoidable topic is the precautions for use, because the correct use can ensure normal and effective production. As a professional briquetting machine manufacturer, Zhongyuan summarizes several precautions for using the briquetting machine production line ,For reference.

1. Familiar with the equipment and use it skillfully

Operators must be proficient in the structure and performance of the ball press equipment production line and the role of each component. Only by understanding the principle of the equipment, the structure and performance of each part, can the ball press be used correctly and better, so as to avoid some unnecessary errors. , Resulting in dangerous situations such as equipment damage and safety accidents.

2. Ensure lubrication measures

For mechanical equipment, the interaction between parts and components, and between parts and parts, is the basic principle of transmitting equipment power. If the transmission components such as bearings and gears cannot be properly lubricated, it may cause them to be lubricated. The transmission and work are stuck, or even damaged during hard work, which affects safety and normal production. Therefore, lubricate the parts marked in the lubrication diagram while keeping the lubrication points clean.

3. Pay attention to check the production line and equipment

When the ball press equipment production line is in operation, pay attention to check that the bearing temperature of each part does not exceed 60℃, and check whether the bolts of each part are loose, whether there are abnormal noises in the transmission part, and whether the equipment is abnormal. If there is a problem with the equipment parts, it is necessary to stop work in time to maintain the equipment to prevent accidents.

4. Ensure cleanliness

A clean and tidy working environment is also one of the necessary environments to improve work efficiency. The ball press production line processes powdery materials, so it is normal for dust to be present during work, but after finishing work, it is necessary to deal with the dust floating on the equipment in time. In order to prevent dust from entering the equipment and abrasion of equipment parts, in addition to the working area of the ball press production line, it is necessary to ensure the sanitation and cleanliness of other areas, so that employees have a good working environment.

5. Adhere to the "Four Sets" principle

The operators of the ball press production line must abide by the "four determinations" principle, that is, determine the project, determine the personnel, determine the time, and determine the measures. The "Four Sets" principle of safe production is the basic requirement to ensure safe production, and it is also the basic management method. No matter how high the production output is, it is not as important as safe production.

The above are the precautions for the ball press production line summarized by the ball press manufacturer. In general, safe production is the foundation of production. Not only the safety of equipment, but also the safety of personnel and the safety of products are very important.

Official Agent of ZY MINING in Russia.

Please enter here.

Add: Luoxin Industrial Zone,Luoyang City,Henan Province P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com