-

Products

-

Application

The ball press is an important molding equipment for many materials. As one of the core components of the ball press, the quality of the roller skin of the ball press seriously affects the production efficiency and quality of the ball press. It also affects the pressure of the ball press. Service life, frequent replacement of roller skins will certainly cause disassembly and wear of the ball press. Since the roller skin is so important, it is necessary to ensure its overall quality during processing and production. The staff of the roller skin manufacturer has organized the production process of the roller skin of the ball press for your reference.

There are two methods for manufacturing the roller skin of the ball press machine, one is through casting and the other is forging.

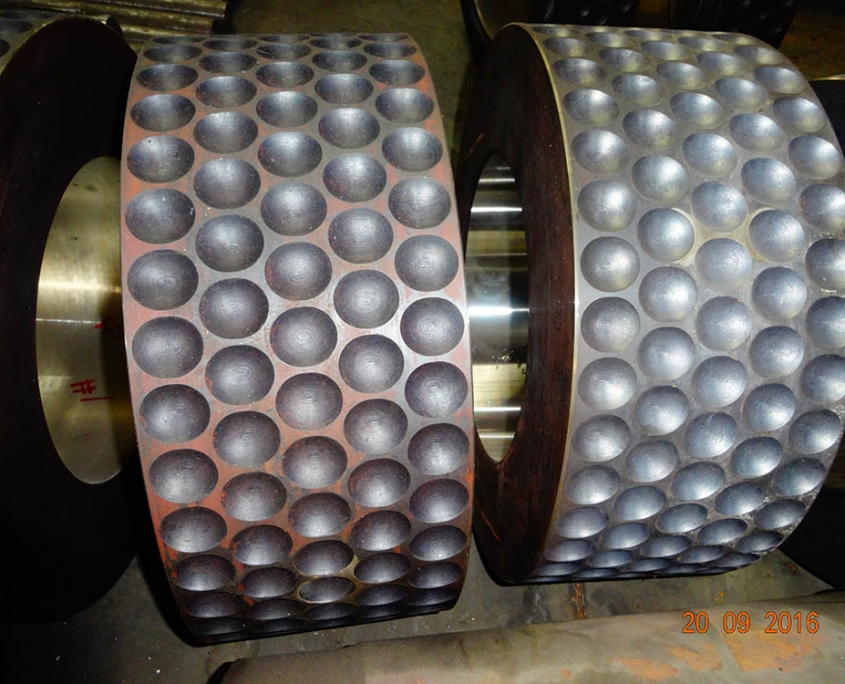

The roll skin processed by casting is the common 65 manganese spring steel roll skin. The main production method is to smelt steel, cast it in the roll skin mold, and remove it for cooling after cooling to make the surface size, inner diameter and ball and socket size meet the requirements , And then heat treatment to make the hardness of the roller skin meet the requirements.

The roll skin made of 65 manganese spring steel due to the characteristics of the material itself will cause hardening during turning, so it is necessary to complete the feed once during turning, otherwise the heat generated between the tool and the roll skin during turning It will cause a hardened layer. Once the cutter contacts, it is easy to cause the cutter head to crack and damage the surface of the roller skin; after turning the casting type roller skin, pay attention to the heat treatment, use oil quenching during quenching, and use warm water during tempering Quick cooling to avoid the second type of temper brittleness.

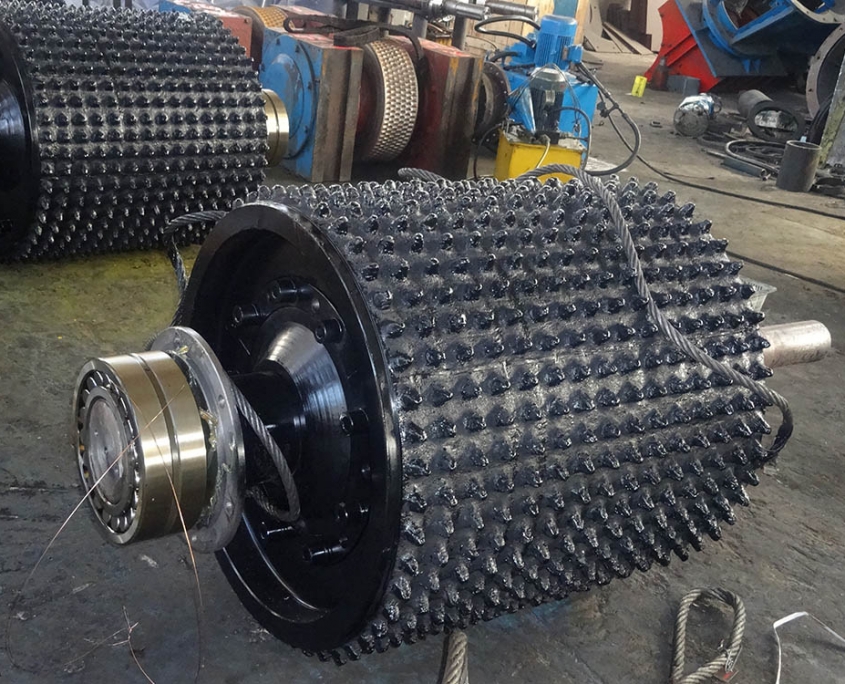

There are two main types of forged roller skins, one is 9 chromium 2 molybdenum alloy steel and the other is bearing steel. The main difference between the production of this type of roller skins and the casting roller skins is that the casting roller skins are directly cast by casting molds, which cannot be welded due to the material characteristics, while the forged roller skins can be processed by welding. The part of the roller skin is welded as a whole, and then heat treatment process.

The forged processing roller skin is stronger than the casting roller skin, and the wear resistance is also higher than the casting roller skin. It has a wider application range, lower machining requirements, multiple feeds, and the ball socket can be engraved and worn according to actual needs. The post-repairability is better; the bearing steel in the forged roller skin is a material with better use characteristics than 9Cr2Mo, hardness and wear resistance on the market today, and it is very suitable for the compression molding of many hard materials.

It can be seen from the above that in the production of the roller skin of the ball press, turning and heat treatment are two processes that have a great influence on the quality of the roller skin. For the casting roller skin, it is very difficult to turn the roller skin with a large diameter. At the same time, it also needs to achieve one-shot shaping, which is a test of the technical level of the lathe, and it must ensure the use of media and temperature control during heat treatment. Therefore, the roller skins of this type of ball pressing machine on the market are used on smaller ball pressing machines, and The hardness is not high enough, and the suppression of mineral powder materials cannot be used.

The ball presses produced by Luoyang Zhongyuan Mining Machine Manufacture Co., Ltd. all use bearing steel forged roller skins, which are suitable for welding in the same way as 9 chromium 2 molybdenum, easy to repair, and the machining process can be fed multiple times, and the machining accuracy It can be guaranteed, but it is more wear-resistant than 9 chromium 2 molybdenum roller skins and has a longer service life, which can reduce the amount of roller skin replacement.

Official Agent of ZY MINING in Russia.

Please enter here.

Add: Luoxin Industrial Zone,Luoyang City,Henan Province P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com