-

Products

-

Application

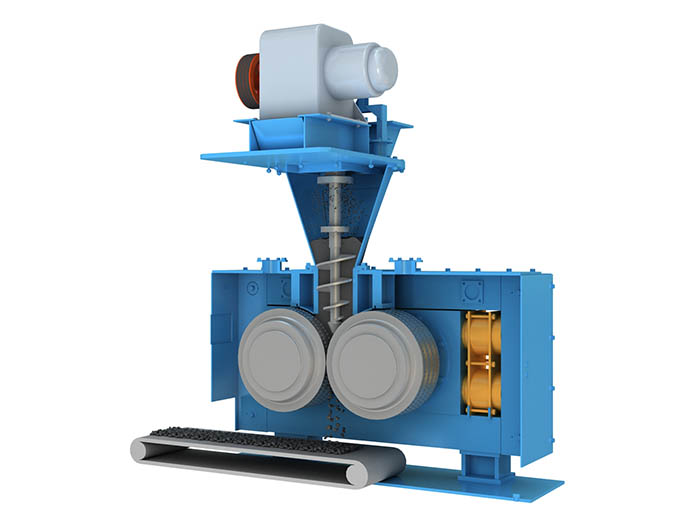

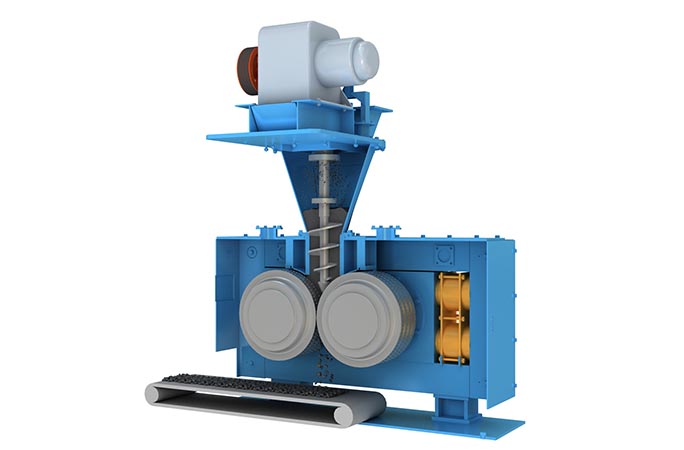

As a molding equipment, the ball press machine is very important in all industries, whether it is reprocessing of materials, or for convenient transportation, or direct molding, it plays a very important role. If you buy a ball press for the first time, we don't know how to choose a variety of models, and we don't know which one we need. The ball press manufacturer summarizes the classification of the ball press and learns together. Let's have a look.

In the manufacturing industry, the classification of ball presses is mainly related to pressure. In today's market, ball presses can be basically divided into low pressure, medium pressure, high pressure, etc. In addition, our company has also developed and produced ultra high pressure. Ball machine for materials that require more pressure for forming.

Smaller volume and lower energy consumption, different press roller pressure ratios can be adjusted according to different materials, ranging from 0-15t/cm. It is specially designed by our company for universities, laboratories, design units and factories and mines. The small experimental equipment manufactured is 1920*2100*1640 (unit mm) and is mainly used for small-scale simulation production.

Mainly relying on the material weight to enter the rolling zone to suppress the material with higher bulk density. According to different models, the line pressure ratio is between 2.5-3.0 (t/cm). The medium pressure ball press will change the structure of the traditional external gear transmission. In order to adopt the structure of the double-shaft reducer, the precision of the roller is effectively improved, and the gear of the reducer adopts a hard-toothed gear, which greatly improves the performance and service life of the reducer.

Mainly used for pressing materials that are difficult to form. Compared with medium pressure, the line pressure ratio varies from 5-11 (t/cm) according to the model. The pre-press machine adopts speed-regulating motor, and all wear parts are welded. Wear-resistant alloy for improved performance and longevity, hydraulic standing, adjustable pressure and overpressure protection. Among today's molding equipment, high pressure ball presses are widely used. Many of the types of ball presses mentioned below are actually one type of high pressure ball presses.

Designed for the production of finer particles (above 300 mesh) and lighter weight, the pressure of higher pressure is larger, the line pressure ratio is between 20-25t/cm, and the pre-presser is used to scrape the nozzle. The arc baffle is made of wear-resistant composite material, and the roller sleeve is composed of multiple contact seals, which greatly increases the sealing property of the triangular compression zone and effectively protects the roller sleeve from damage.

For the user, the pressure of the ball press is only a parameter, and the material to be pressed is the key factor for the classification of the ball press. The parameters required for different material forming are not the same, thus the various materials are separated. Various ball presses, such as dry powder, briquette, mineral powder, bauxite, etc.

It is mainly used to suppress some moisture-free materials, such as quicklime powder, alumina powder, etc., water should not be added during the molding process, and the air between the materials is discharged and extruded into balls by high pressure, which is used in some metallurgical and chemical industries. .

It is mainly used for the forming of some metallurgical wastes, as well as materials for re-returning the medicines, such as chrome ore powder, manganese ore powder and dust ash. For material sizes between 0 and 3 mm, the pressure requirements are within the scope of high pressure ball machines.

It is suitable for pressing some materials which contain a certain amount of water, or need to add a certain amount of water or binder, and can also be subjected to anhydrous press forming. The molding process of the briquette ball press is divided into cold pressing and hot pressing, mainly in cold pressing forming, and the cold pressing determines whether to add the binder according to the bonding force between the materials. The briquette press is a medium and high pressure forming equipment. The configuration of different materials is slightly different, and customized production is required.

The above three ball presses have obvious requirements for the production process, while other ball presses require only a slight difference, but in general, there is no water, water and the binder to be added. Wait, some materials require the same material to be different in the molding process.

The diameter of the pressure roller is within 800mm. There are three models of the roller diameter of the small pressure ball machine produced by our company:

(1) Roller diameter 520mm ball press, under the roller diameter, the total pressure of the ball press is 100t, 150t.

(2) Roller diameter 650mm ball press, under the roller diameter, the total pressure of the ball press is 120t, 220t.

(3) Roller diameter 750mm ball press, under the roller diameter, the total pressure of the ball press is 150t, 200t, 300t.

Suitable for small and medium-sized enterprises in the processing of various materials, especially the powdery materials are not particularly small and medium-sized enterprises, the small overall size is small, the space requirements for the plant are not particularly harsh, the weight is light, if necessary, can be Move the adjustment device position during shutdown. However, the small ball press has a small roll surface, so the output is not particularly large. If it is a slightly larger medium-sized enterprise that has a large demand for production, it is more suitable for a medium-sized ball press.

The pressure roller is between 800mm and 1200mm in diameter:

(1) Ball diameter 800mm ball press, the total pressure of the ball press is 380t.

(2) Roller ball with a diameter of 1000mm, the total pressure of the ball press is 300t, 350t, 500t, 540t, 800t.

(3) Roller ball with a diameter of 1200mm, the total pressure of the ball press is 300t, 800t and 1000t.

Compared with small-scale production and wider application range, both medium-sized enterprises and large enterprises can meet the production and molding pressure, and the roll surface is large enough and wide, and the output is high, but for the site. It requires a lot of space, and it may be necessary to install supporting facilities to help feed and dry.

The pressure roller has a diameter of 1200mm or more. The Central Plains produces a ball press with a diameter of 1400mm. The total pressure is divided into 360t and 1000t. The body is larger and the output is higher. At the same time, it can meet some special molding needs, and is suitable for some large coal, mining and metallurgical industries.

The above is the classification of several common pressure ball machines. It can be seen that there are many types of such molding equipment, and there may be more than these. At the same time, for different pressure ball machine manufacturers, the classification of the pressure ball machines is not the same. However, when choosing, it is always inseparable from the size, output and use of the ball press.

Add: Luoxin Industrial Zone,Luoyang City,Henan Province P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com

Official Agent of ZY MINING in Russia.

Please enter here.

Add: Luoxin Industrial Zone,Luoyang City,Henan Province P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com