-

Products

-

Application

Briquetting is the process of compressing loose biomass materials into a compact, high-density form called a briquette. This process can make it easier to transport, store, and use these materials for various purposes, including as fuel.

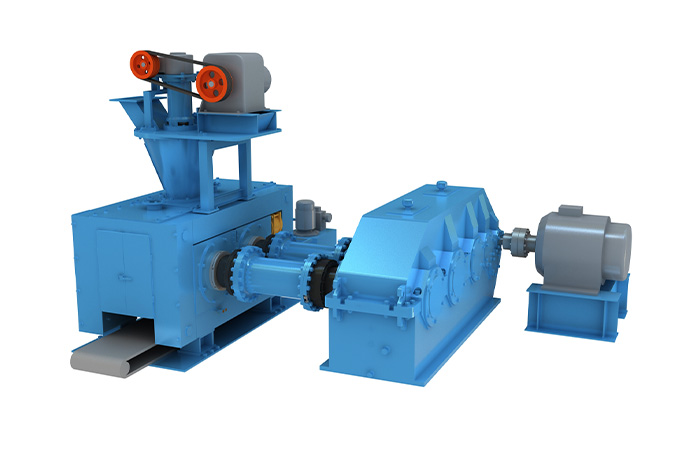

This method involves using a mechanical press to compress the biomass material into a briquette. The press applies pressure and heat to the material, which causes it to become denser and take on a more uniform shape.

This method uses a screw to compress the material into a briquette. The screw rotates and pushes the material through a die, which forms it into the desired shape.

This method uses a piston to compress the material into a briquette. The piston moves back and forth within a cylinder, compressing the material against a die to form the briquette.

This method involves mixing the biomass material with a binder and then heating it to a high temperature to form a briquette. The binder helps hold the material together and gives it the necessary strength.

This method involves adding chemicals to the biomass material to help it bind together and form a briquette. The additives can include things like lime, cement, or starch.

The choice of briquetting method will depend on various factors such as the type of biomass material being processed, the amount of material to be processed, the desired briquette shape and size, and the available equipment and resources.

Add: Luoxin Industrial Zone,Luoyang City,Henan Province P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com

Official Agent of ZY MINING in Russia.

Please enter here.

Add: Luoxin Industrial Zone,Luoyang City,Henan Province P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com