-

Products

-

Application

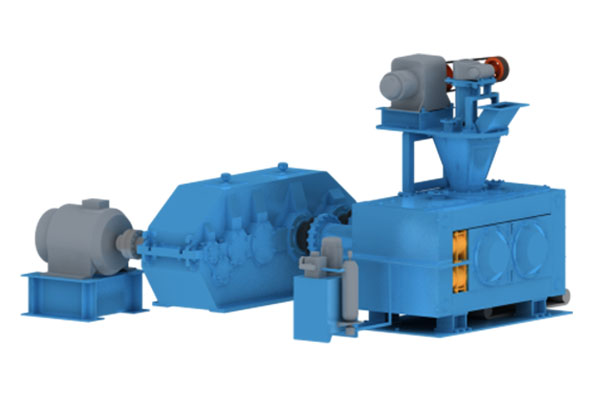

In the production and processing of most powdery or granular materials, in order to transport and use them more efficiently, it is necessary to use briquetting equipment to press these materials into pellets, but some materials are special because of their special characteristics. The physical characteristics and production process of the product can not be pressed into a shape at one time, so it is necessary to choose the second briquetting process of the briquetting machine to compress the material.

Under normal circumstances, when the material cannot be added with any binder and requires a large ball-forming pressure, either high-pressure and ultra-high pressure briquetting machines (such as the high-pressure briquetting machine produced by Zhongyuan Mining Machinery) are used for material compression, or Change the material briquetting process, that is, cooperate with other equipment for secondary briquetting, so in addition to the briquetting machine, the equipment required for the secondary briquetting is as follows:

1. Belt conveyor: the conveying equipment that transports the material powder to the bucket elevator. Through a reasonable site layout, it can simultaneously carry the material after the initial briquetting of the briquetting machine and send it to the bucket elevator at the same time machine.

2. Bucket elevator: convey the material conveyed by the belt conveyor to the conveyor of the grinding and crushing system.

3. Material screening machine: Different granular materials are distinguished through the screen and sent to the grinding and crushing equipment or the supply bin.

4. Distributing chute: the qualified and unqualified balls are distinguished by vibration through the second compression.

5. Grinding and crushing equipment: It can crush and grind large particles and materials that cannot be formed at one time.

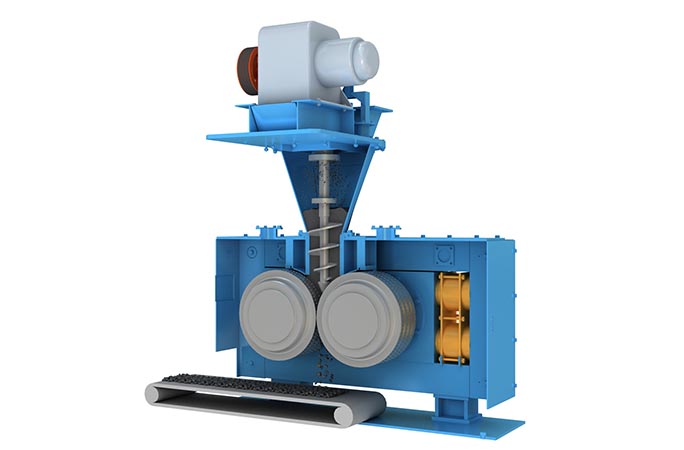

6. Screw conveyor: feed the materials from the supply bin to the briquetting machine after proportioning and metering.

1. Firstly, the ground material in the supply bin is sent to the briquetting machine through the screw conveyor for the first briquetting, and the material after the first pressing is sent to the sieving machine through the elevator for vibrating screening;

2. The screened material is sent to the grinding and crushing equipment for processing and then discharged into the intermediate bin as the aggregate for the secondary briquetting;

3. The screened material enters the fine powder silo, and then the fine powder and the aggregate in the intermediate silo are sent to the briquetting machine through a screw conveyor to perform secondary briquetting according to a certain ratio;

4. After the secondary compaction, the pellets will enter the distribution chute through the elevator. Under normal circumstances, the pellets will be vibrated and screened by the distribution chute. The finished pellets will go directly to the next processing stage, and the non-finished pellets will be sent to crush again The machine is crushed and then ground, and then returned to the supply bin of the briquetting machine, as the ratio of aggregate and fine powder for secondary briquetting.

1. In order to ensure sufficient material supply to the briquetting machine, in the case of a large amount of material being fed by the feeder, an overflow material outlet should be set at the screw feeding device, and the overflow material should be returned to the briquetting machine supply bin through a lifter.

2. The distribution chute should also be equipped with an overflow. When the distribution chute is full, the ball will flow out from the overflow to the vibrating screening machine, and the sieved material will enter the green ball circulation bin for storage. When the system fails, the balls in the green ball circulation bin are lifted by the elevator to the distribution chute and circulate again.

3. Before proceeding with formal processing, pay attention to adjust the ball-forming pressure of each briquetting machine and the symmetry of the press roller to avoid secondary briquetting and mold sticking caused by equipment problems.

4. Pay attention to the feeding route of each conveying equipment and screening equipment, and avoid the mixed storage of primary processing and reprocessing materials in the site design and process, so as to ensure that the material ratio of the secondary briquetting is more accurate.

The above content is a detailed introduction to the briquetting process. Basically, for materials that cannot be formed at one time, the ratio of fine powder and aggregate is used for secondary briquetting, which can greatly increase the spheroidization rate and the volume of the pellets. Density to ensure the quality of the ball.

Official Agent of ZY MINING in Russia.

Please enter here.

Add: Luoxin Industrial Zone,Luoyang City,Henan Province P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com