-

Products

-

Application

The hammer head of the crusher is an important part to ensure the normal production of ore materials. It not only affects the output of sand and gravel aggregates, but also affects the quality of finished products. Many users are deeply troubled by the serious wear of the hammer head. So how to deal with it? In response to this problem, the crusher manufacturer gave us a detailed introduction.

There are so many types of crushers on the market, including crushers with hammers and crushers without hammers. Some people say that since the hammer head is often worn, it is better to choose a crusher without a hammer head. In fact, although hammer crushers have the trouble of wear and tear, other crushers also have wearing parts, but they are not hammer heads.

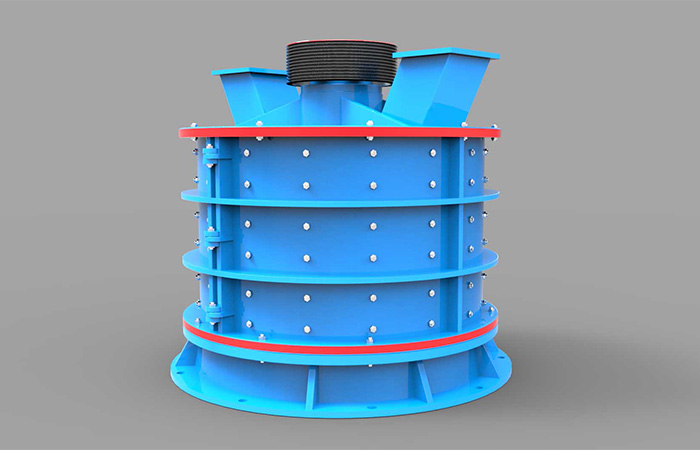

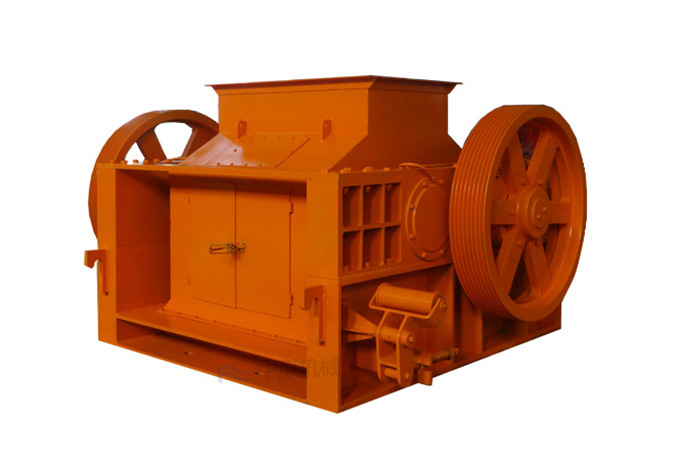

Common crushers with hammers on the market include: impact crushers, hammer crushers, fine crushers, vertical compound crushers, etc. This kind of crusher with a hammer is generally an impact crusher. The aggregate produced has a better particle size and will be broken along the gaps in the ore. There are few cracks in the particles. The finished product is often cubic and has a high degree of gradation. Therefore, Many people will choose this kind of impact crusher with hammer head.

In order to solve the problem of serious wear of the hammer head of the crusher, it is necessary to find out the cause of the serious wear of the hammer head of the crusher and prescribe the right medicine. The main reasons for the serious wear of the hammer head of the crusher are the material of the hammer head, the manufacturing quality and structural design, the technical design of the crusher, the feeding situation and the clearance of each part of the structure.

Reason 1. Hammer head material

The hardness and toughness of the hammer head are one of the reasons that affect the wear of the hammer head. Generally, the greater the hardness, the greater the wear resistance of the hammer head, but as the hardness increases, the impact toughness of the hammer head will decrease. Therefore, the key to improving the wear resistance of the hammer head is to find a material with both hardness and good toughness.

Treatment method: choose the hammer head of high wear-resistant material, such as high manganese steel, high chromium cast iron, low carbon alloy steel, etc.

Reason 2. The production quality of the hammer head

The manufacturing process of the hammer head also determines the key factor of its wear resistance. Obviously, if the surface or interior of the hammer head is defective during the production process, such as shrinkage cavity, crack, transgranular and other conditions, not only the hammer head will be easy to wear, but even the hammer head will break.

Treatment method: adopt mature hammer head production technology, formulate reasonable casting and heat treatment process. For example, when manufacturing high-chromium cast iron hammers, adopt vertical casting and rational use of external chilled iron, and strictly control the temperature at the same time, so that the produced hammers have good solidification sequence and feeding conditions, and the internal structure is dense, and the coarse grains are weakened.

Reason 3. The structure of the hammer head

The structure and shape of the hammer head also affect the wear. The heat treatment performance and internal structure of hammer heads with different structures and shapes are very different, which in turn affects the wear resistance. The hammer head with special size and thickness has a greater impact. In addition, the thicker the hammer head, the harder it is to harden and the worse the wear resistance.

Processing method: optimize the structure of the hammer head.

Reason 4. The technical parameters of the crusher

The technical parameters that affect the wear resistance of the hammer head of the crusher include the power and speed of the rotor. These two parameters reflect the linear velocity and impact force of the hammer head, and are related to the production capacity of the crusher and the degree of impact hardening of the hammer head. Impact hardening If the degree is good, the service life will be extended. When the speed of the rotor is too low, the production capacity will be low, resulting in poor impact hardening of the hammer head and poor wear resistance; It will cause strong wear on the hammer head and the liner, which is not good for the life of the hammer head, and will also increase power consumption.

Treatment method: optimize the technical parameters, control the power and speed of the rotor, neither too high nor too low.

Reason 5. The gap between the components in the crusher structure

The gap that affects the wear of the hammer head of the crusher includes the gap between the rotor body, the liner of the crusher, and the hammer head. In severe cases, it can also cause blockage.

Treatment method: adjust the clearance of the rotor, hammer head and other parts to make it within an appropriate range.

Reason 6. The feeding situation of the crusher

There are two main feeding conditions that affect the life of the hammer head, one is the material properties, and the other is the feeding method.

Material properties include particle size, hardness, moisture content, etc. The particle size of the material should not be too small, and the size of the collision impulse is directly related to the degree of work hardening and wear resistance of the hammer head; if the hardness of the material is too large, the wear speed of the hammer head of the crusher will be accelerated; if the water content is too high, the material will easily bond into agglomerates , resulting in accumulated material, which aggravates the wear of the hammer head.

Different feeding methods will cause different drop from the material to the rotor, which will affect the collision impulse when the hammer hits the material.

Treatment method: ensure that the particle size of the material is not too small, the hardness is not too large, and the water content is not too high; the feeding method is kept stable and even.

The simpler method is to start with the material. The commonly used materials for the hammer head of the crusher are high manganese steel, high chromium cast iron, low carbon alloy steel and so on. You can choose according to your needs.

Gaomeng steel has good toughness, and its main feature is that under the action of large impact or contact stress, the surface layer will quickly produce work hardening, and the work hardening index is about 5 to 7 times higher than other materials. It not only has high wear resistance, but also has low price. But if the impact force is not enough, the wear resistance of Gaomeng steel cannot be fully exerted.

High chromium cast iron is a wear-resistant material with good wear resistance, but its toughness is relatively low and it is prone to brittle fracture. However, in response to market demand, people have produced composite hammer heads, in which high-chromium cast iron is embedded in the head of high-manganese steel or low-alloy steel hammer heads, or the working part of the hammer head is made of high-chromium cast iron, and the hammer handle is made of carbon steel. Steel, which is the combination of the two and hence its name, makes the head have high hardness and the hammer handle has high toughness, giving full play to the respective advantages of the two materials and overcoming the disadvantages of a single material.

Low-carbon alloy steel is mainly an alloy steel structure containing various elements such as lattice and molybdenum. It has high hardness and good toughness. Its matrix structure includes martensite, bainite or bainite+martensite composite structure. Under the same working conditions, its service life is at least twice as long as that of high manganese steel hammer heads.

To sum up, we sorted out the causes and treatment methods of severe crusher wear, as well as suggestions for choosing a good hammer head. In fact, the wear of the hammer head of the crusher is inevitable, but what we can do is to slow down its wear speed as much as possible and prolong its service life. In addition to the material of the hammer head, you should also choose according to the properties of the materials you own. In addition, you should also pay attention to the operation method during the production process, so that the wear of the hammer head of the crusher will naturally slow down.

Add: Luoxin Industrial Zone,Luoyang City,Henan Province P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com

Official Agent of ZY MINING in Russia.

Please enter here.

Add: Luoxin Industrial Zone,Luoyang City,Henan Province P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com