-

Products

-

Application

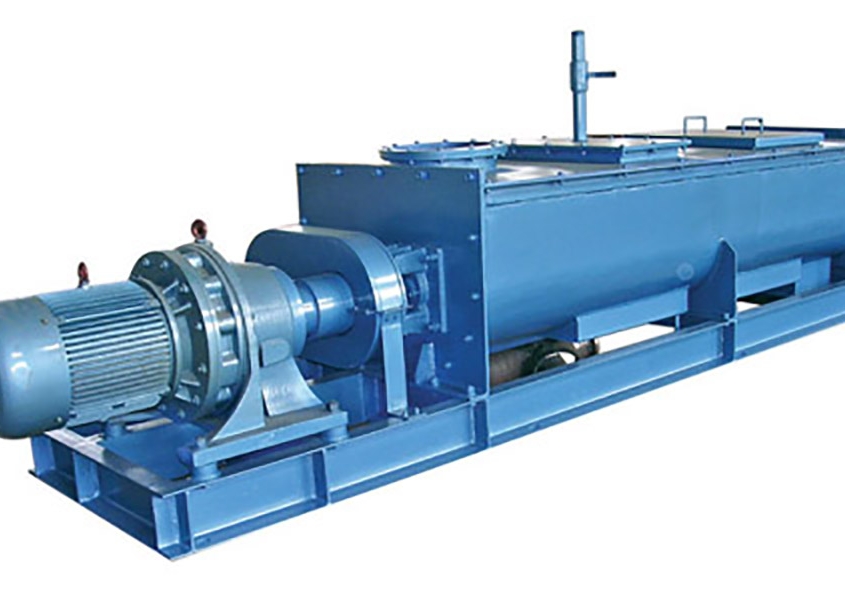

In industries such as metallurgy, mining and refractory, in order to mix and humidify loose materials, various mixing devices are often used. Among them, the double-shaft mixer is favored by various industries because of its high degree of automation and continuous mixing. These advantages are inseparable from the structure of the dual-shaft mixer. Let's take a look at the structure of the dual-shaft mixer.

The motor is decelerated by V-belt drive and planetary reducer, from high speed to low speed, and the power is transmitted to the mixing spindle through the spline shaft and spline shaft sleeve; at the same time, the synchronous drive shaft is connected between the two reducers to ensure the two mixing spindles Synchronize. The advantages of this system are: smooth transmission, large transmission torque, and high cost performance.

The shaft end seal is composed of a bearing seat, a bearing, and a lubricating oil path to support and position the agitating shaft. At the same time, the high-pressure lubricating oil path lubricates, dissipates, and seals the support base and the agitating shaft head to form a sealed oil chamber To ensure that the mud does not erode the bearing seat and the mixing shaft.

The lubrication device of the mixer is one of the core components of the mixer, and its action directly affects the working efficiency and service life of the mixer. The lubrication system is composed of electric lubrication pumps and oil pipes. The grease is pressurized by an electric pump and reaches the four shaft ends of the mixer. The pressure grease forms a high-pressure protective layer on the shaft end to prevent mud from invading the shaft end, thereby protecting the shaft end of the bearing and the stirring shaft.

Automatic lubrication points: 4 (shaft end seal);

Manual lubrication points: 10 (4 spindle bearings, 2 discharge door bearings, 4 shaft end seals);

Lubrication system: A centralized lubrication system is used. There are four pumps to seal the four shaft ends.

The mixing cylinder is a w-shaped double barrel bent from a wide and thick steel plate. It has a strong yield force under the support of a specially designed and manufactured frame. The supporting part can also make the cylinder rigid enough to ensure a double bedroom. The parallelism of the axis and the concentricity of the single axis. Each side is equipped with a maintenance platform, which can be retracted and supported according to needs, which is convenient for operation and maintenance. In order to prevent the abrasion of the mixing cylinder, a high-hardness high-chromium wear-resistant lining plate is installed inside and on the side of the mixing cylinder. The lining plate is fixed on the cylinder block with bolts. Liner blades: high chromium wear-resistant cast iron. Lifespan is up to 70,000 cans.

The mixing device is composed of a main shaft, a mixing arm, a blade, a scraper, etc. The two mutually parallel main shafts of the mixing device are each equipped with 7 mixing arms, and the two adjacent main mixing arms on the same main shaft are distributed at 60 °. The relative angle relationship is fixed, and this fixed relationship is guaranteed by the coupling between the two reducers (in view of this, do not easily disassemble the coupling). Each agitator arm is designed according to hydrodynamics to make it stronger and reduce the resistance during agitation, as well as reduce the amount of wear.

It is composed of the main body of discharge door, cylinder and proximity switch. During automatic operation, three states of fully open, fully closed, and half open are generally set. During operation, high-pressure gas is passed to the cylinder, and the cylinder drives the swing lever to rotate the door body around the bearing seat to achieve the purpose of opening and closing the door.

Two access doors are installed on the upper cover for use during inspection. A safety switch is installed at the maintenance door. When the maintenance door is opened, the mixer stops working. So as to ensure that the maintenance personnel can maintain the safety inside the cylinder. An observation window is opened on a maintenance door for the staff to observe while the mixer is working. The water pipe is arranged reasonably so that the water can be evenly distributed in the cylinder. More importantly, its conical spiral nozzle can effectively prevent clogging.

The above is the structural knowledge about the twin shaft mixer. It can be seen that this equipment is very excellent and efficient from design to production, which can meet the mixing needs of various related industries.

Official Agent of ZY MINING in Russia.

Please enter here.

Add: Luoxin Industrial Zone,Luoyang City,Henan Province P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com