-

Products

-

Application

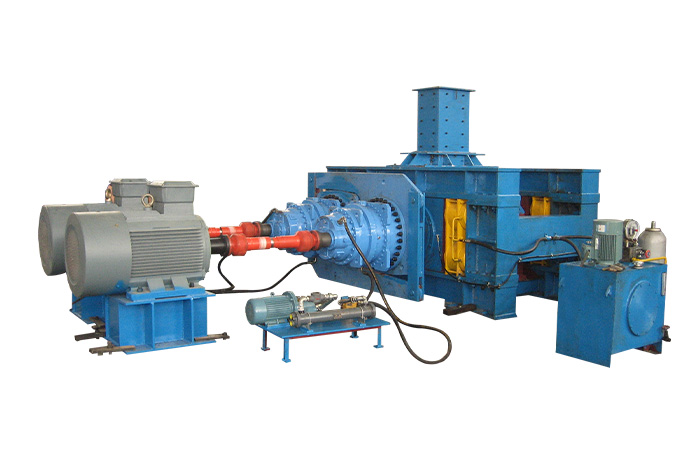

The high-pressure roller mill is used as a material grinding equipment with excellent performance in mining enterprises. It uses the principle of static pressure pulverization. However, because the equipment is in operation, the force of each part is large, resulting in large vibrations. In order to ensure the high-pressure roller mill The machine is stable and firm, and the frame and base need to be installed strictly in accordance with the specifications. Below, the editor of Zhongyuan has compiled the installation methods and precautions of the high-pressure roller mill frame for your reference.

(1) Before installing the base of the high-pressure roller mill, use kerosene to clean the anti-rust oil, and then place it on the base plate of the horn. The contact area between the base and the horn in several shifts is required to reach 80 of the total area. %;

(2) Insert the base and shim base plate into the anchor bolts, use a level to roughly adjust the level of the base, then clean the contact surface of the base and the frame with kerosene, and install the frame on the base after completion;

(3) Adjust the shim and use a feeler gauge to check the gap between the base and the frame. After the adjustment is completed, use a torx wrench and a hydraulic electric wrench to tighten the bolts four times, and apply thread tightening glue before tightening. Effectively prevent bolt loosening caused by mechanical vibration.

(1) Use kerosene to clean the roller slide of the rack, and then check and wipe the surface of the slide;

(2) Use a level ruler to put on the slide rail, adjust the shim to make the slide initially level, and then use a frame level meter and a ruler to measure the slide, and adjust the shim for fine leveling;

(3) After the fine leveling is completed, use electric welding to fix the side of the shim to make it firm and stable;

(4) Tighten the bolts four times with a Torx wrench and a hydraulic electric wrench, and apply thread tightening glue before tightening, which can effectively prevent the bolts from loosening caused by mechanical vibration.

1. The contact surface between the base and the shim base plate should be free of burrs;

2. The gap between the contact surface of the base and the shim base plate should be less than 0.02mm, and check with a 0.02mm feeler gauge;

3. When using a level to roughly level the base, the level deviation should be less than 2mm;

4. The roller slide of the frame should be free of burrs and damage;

5. After the frame is leveled, the longitudinal and horizontal horizontality error shall not be greater than 0.02mm;

6. After the installation of the base and the rack, check the deviation in time and record the result of the check.

The above is the whole content of the installation method and precautions for the frame of the high pressure roller mill. I hope to help you. The installation of the frame and the base is not firm, which is one of the main reasons for the vibration of the high-pressure roller mill. On the one hand, noise affects the work of the on-site operators, and on the other hand, it may cause the transmission system of the high-pressure roller mill to appear during the vibration process. Failure and premature wear of parts, so like other components, it is necessary to pay attention to their installation conditions.

Official Agent of ZY MINING in Russia.

Please enter here.

Add: Luoxin Industrial Zone,Luoyang City,Henan Province P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com