-

Products

-

Application

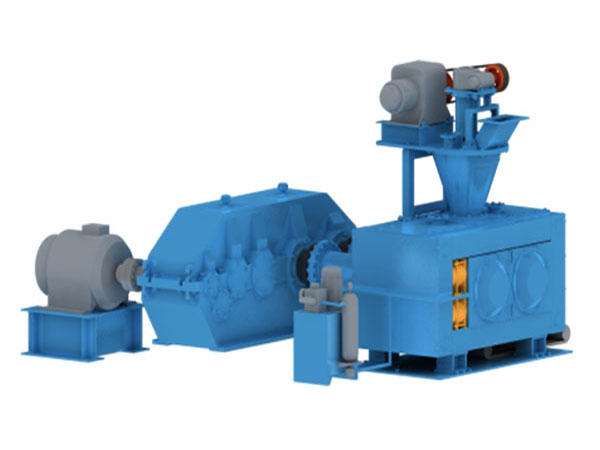

Briquetting machine can improve the utilization rate of waste materials, and the pressed materials are energy-saving, environmentally friendly, and easy to transport. Everyone who uses a briquetting machine must think that it can be briquetted with good quality and high productivity, but this is actually related to the requirements, not only related to the quality of the briquetting machine. So, What affects the efficiency of briquetting machine? The editor made a detailed summary of these issues for everyone, let's take a look together.

First of all, the main factor that can affect the production efficiency of the briquetting machine is the performance of the briquetting machine. If you choose a briquetting machine equipment, if the quality of the equipment is not up to the standard, there will be some faults and problems frequently in operation, so naturally, it goes without saying that the model selection and other big ones will be futile. , And the amount of investment is also relatively large. Therefore, it is one of the key factors to ensure the production capacity of briquetting machine equipment that can operate with high efficiency without failure.

The mechanical strength of the Briquetting machine is a prerequisite for material compression molding. What affects the mechanical strength of the briquetting machine is the pressure of the briquetting machine. The mechanical strength directly affects the advantages of the product in the subsequent industrial chain. Therefore, the influence of the mechanical strength and pressure of the briquetting machine is undoubtedly the most important.

Moisture content has a direct and significant impact on the molding of briquetting machine compressed materials: when the material content rate is too low, the material compressed by the briquetting machine is prone to cracks; when the material moisture content is too high, it is easy to cause the product and the pressure roller to bond. As a result, the shape of the product is not complete, and the texture of the material pressed by the briquetting machine is soft, which affects the production efficiency of the briquetting machine, and the pressed finished product does not meet the hardness requirements of a qualified finished product. Users can control the amount of water added by mixing the materials and pre-dry the materials before pressing to control the moisture content of the materials.

Excessive impurities in the material can affect the original performance of the material-affect the improvement of the material properties by the binder and other additives in the material. Impurities with higher hardness and larger particle size can even cause unnecessary damage to the briquetting machine. The user can decide whether to add a pre-screening process to reduce the impurities in the material according to the condition of the raw material. Impurities will affect the affinity between the particles of the material in the compression process, resulting in loose products and low molding effects.

The particle size distribution of the material pressed by the briquetting machine must be reasonable, otherwise the large material particles will raise the surrounding small particles, which will form a "virtual block". The virtual block is intact in appearance, and the mechanical strength of the briquetting machine is secretly insufficient. Uneven material particle size will also cause the production efficiency of the briquetting machine to decrease. It should be noted that when the material particles are under pressure in the body of the briquetting machine, an opposing force will be generated between each other. At this time, the binder can be used to offset it.

The above is the answer about What affects the efficiency of briquetting machine, I hope it can be helpful to everyone. The operators of the Briquetting machine must be specially trained before they can officially start their jobs. Luoyang Zhongyuan Mining Machine Manufacture Co., Ltd. produces and sells metal briquetting machines, which can be professionally customized according to customer needs. Interested parties are welcome to come to consult.

Official Agent of ZY MINING in Russia.

Please enter here.

Add: Luoxin Industrial Zone,Luoyang City,Henan Province P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com