-

Products

-

Application

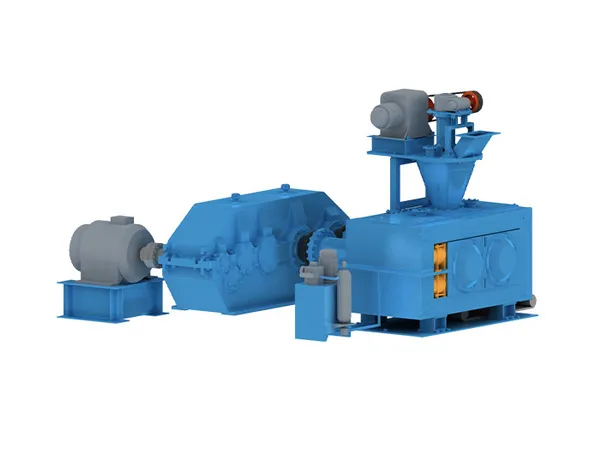

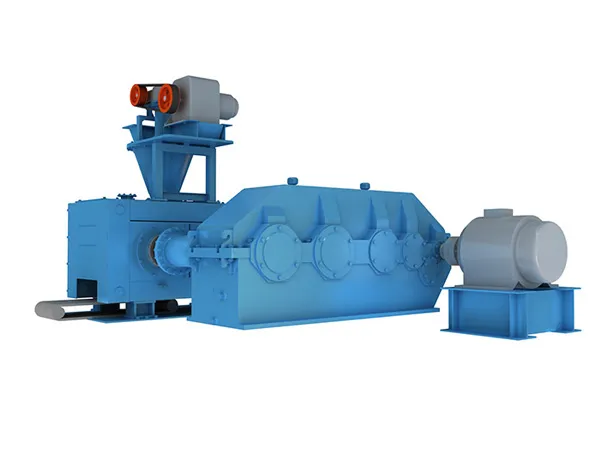

Briquetting machines compress loose, often discarded, materials like sawdust, agricultural waste, and even metal scraps into dense, solid blocks called briquettes. Using a briquetting machine to form briquettes offers several advantages, especially in waste management, energy production, and resource utilization.

Volume Reduction: Briquetting significantly reduces the volume of loose raw materials like sawdust, agricultural waste, and charcoal dust. This makes storage and transportation much more efficient and cost-effective.

Increased Calorific Value/Energy Density: Briquettes have a higher density than their raw material counterparts, leading to a higher calorific value per unit volume. This means they burn hotter and longer, making them a more efficient fuel source.

Improved Handling and Storage: The uniform size and shape of briquettes make them much easier to handle, stack, and store compared to loose biomass or dust. This also reduces material loss due to scattering.

Waste Utilization: Briquetting transforms various organic wastes (like agricultural residues, forest waste, and industrial by-products) into valuable fuel, reducing landfill burden and promoting a circular economy.

Reduced Deforestation: By providing an alternative fuel source, briquettes can help reduce reliance on firewood and charcoal made from trees, thereby mitigating deforestation.

Cleaner Burning: Compared to raw biomass, briquettes often burn more completely and with less smoke, potentially leading to reduced air pollution.

Lower Transportation Costs: Due to reduced volume and increased density, fewer trips are needed to transport the same amount of energy, saving on fuel and logistics.

Value Addition: Transforming waste into briquettes creates a new marketable product, adding value to what would otherwise be discarded.

Consistent Quality: Briquetting machines produce briquettes of consistent size, shape, and density, which allows for more predictable and efficient combustion in stoves and boilers.

Reduced Moisture Content: The briquetting process, especially with some machines that involve heating, can help reduce the moisture content of the raw material, further enhancing its burning efficiency.

Wide Range of Raw Materials: Briquetting machines are versatile and can process a diverse array of materials, including:

Sawdust and wood chips

Agricultural residues (rice husks, coffee husks, groundnut shells, cotton stalks, bagasse)

Charcoal dust

Paper waste

Some industrial wastes

In summary, briquetting machines offer an effective solution for converting waste into a valuable, efficient, and environmentally friendly energy source, with significant advantages in terms of logistics, performance, and sustainability.

Official Agent of ZY MINING in Russia.

Please enter here.

Add: Luoxin Industrial Zone,Luoyang City,Henan Province P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com