-

Products

-

Application

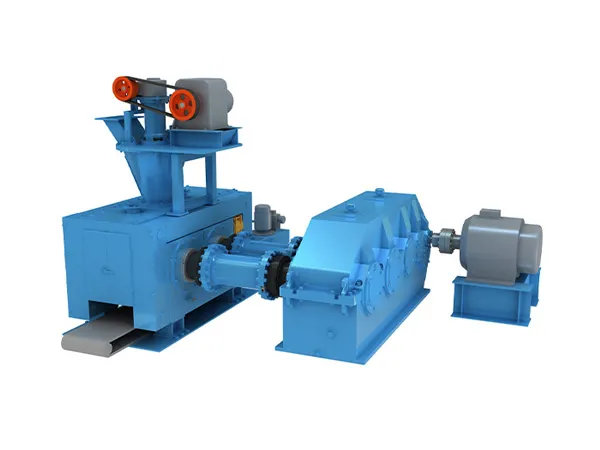

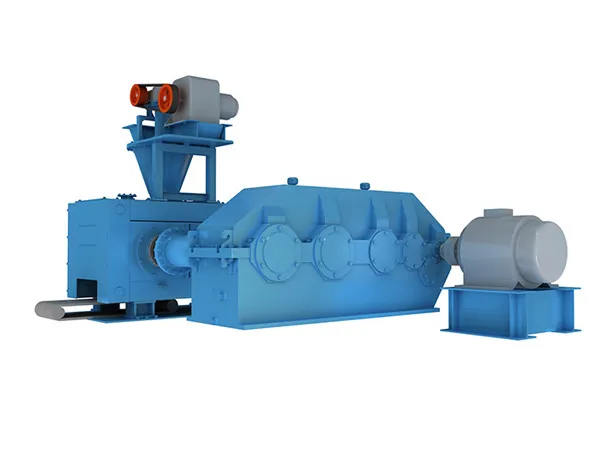

The materials are pressed into the pre- press device of the ball press with certain volume evenly when briquetting machine working, and the stable material position shall be kept in the pre-press device.

The pre-pressing spring in the device will force the materials into the inter-space between the double rollers, then the materials shall be pre-pressed and transited to the arch groove of the pair-rollers.

The roller pits with the same shape are distributed evenly on the rollersurface. The 2 pair-rollers shall rotate at constant speed reversely through engagement drive.

The rollers will suck the materials at the entry into the groove and forcibly compress them.

With the continuous rotation of the pair-roller, the ball shall be taken off by the elastic force and gravity. The roller rotates to compress and form the materials periodically with the continuous operation of the motor to realize the batch production.

Briquetting is a process of compacting biomass, agricultural waste, or other materials into denser and more manageable forms called briquettes. These briquettes can be used as a source of fuel or for various industrial applications.

Definition: Briquetting involves compressing materials into compact, solid, and uniform shapes.

Materials: Common materials include biomass, wood, agricultural residues, paper, and other organic materials.

Purpose: Briquettes can be used for energy production, heating, and as a substitute for traditional fuels.

Preparation: Collect and prepare raw materials. This may involve drying, shredding, and other pre-processing steps.

Feeding: The prepared material is fed into the briquetting machine.

Compression: Pressure is applied to the material to form briquettes. This is typically done using mechanical presses.

Binding Agents: In some cases, binding agents are added to improve the briquetting process and enhance the quality of the briquettes.

Screw Extruder Press: Utilizes a screw to compact materials.

Mechanical Press: Employs a piston or die to apply pressure.

Hydraulic Press: Uses hydraulic power for compression.

Roller Press: Utilizes two counter-rotating rollers to compact materials.

Hopper: Where raw materials are loaded.

Die or Mold: Determines the shape and size of the briquette.

Motor: Powers the machine.

Hydraulic System: In hydraulic presses, this system applies pressure.

Energy Efficiency: Briquettes have a higher energy density than loose materials.

Environmental Impact: Reduces waste and promotes sustainability.

Economic Viability: Cost-effective alternative to traditional fuels.

Transportation and Storage: Briquettes are easier to handle, transport, and store.

Energy Production: Briquettes can be used for heating, cooking, and electricity generation.

Industrial Use: Briquettes can serve as raw material for various industrial processes.

Waste Reduction: Helps manage and reduce agricultural and forestry waste.

Quality Control: Ensuring consistent quality of briquettes.

Feedstock Variation: Dealing with variations in raw material properties.

Market Acceptance: Establishing a market for briquettes.

Technology Adaptation: Adapting to new and advanced briquetting technologies.

Regular maintenance of briquetting machines is crucial for optimal performance.

Safety protocols should be followed to prevent accidents, especially when dealing with hydraulic or mechanical presses.

Ongoing research is essential for improving briquetting technologies, developing new materials, and addressing challenges.

Briquetting contributes to environmental sustainability by reducing the reliance on traditional fuels and managing waste effectively.

Briquetting offers a sustainable and efficient solution for converting various types of biomass and waste into valuable energy sources and raw materials. Continuous innovation, quality control, and market development are critical for the success of briquetting solutions.

Keep in mind that specific details may vary based on the type of briquetting process and machine used, as well as the characteristics of the raw materials involved. Always follow manufacturer guidelines and industry best practices for safe and effective briquetting.

Add: Luoxin Industrial Zone,Luoyang City,Henan Province P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com

Official Agent of ZY MINING in Russia.

Please enter here.

Add: Luoxin Industrial Zone,Luoyang City,Henan Province P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com