-

Products

-

Application

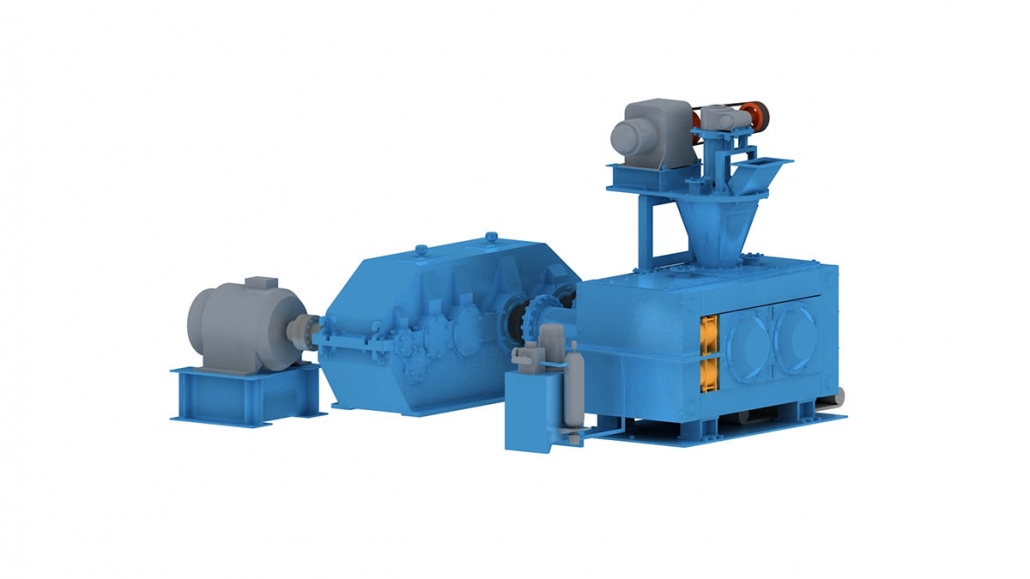

A briquetting machine is a device that compresses a powdered material into a ball. The briquetting machine is widely used to press ball on the following materials, such as aluminum chips, activated carbon, alumina, bauxite, caustic soda, sludge, charcoal, clay, coke, coal, cryolite, fertilizer, plastic , limestone, etc. Its purpose is to reduce dust, control bulk density, return to use, and improve transportation characteristics. In general, because the briquetting machine application industry is relatively extensive, the price varies according to the output, so you should have a complete understanding of the briquetting machine equipment before you start the project.

We have prepared a content directory for you.

1、Briquetting machine meaning

2、Structural composition

3、Technical Parameters

4、Briquetting machine application solution

5、Price range

6、Pictures and videos

In order to reduce environmental damage and save resources and energy, enterprises need to optimize and utilize these materials on the one hand, and on the other hand, they need to improve environmental pollution through some means. Any metallurgical industry waste, auxiliary materials need to be on the furnace, all need to press the ball machine to complete. For example: dust ash, pool mud, scale, steel slag, iron powder, aluminum ash powder, silico-manganese ore powder, and so on. Various materials can be made into dense spheres by forced pressurization and precision processing, and are widely used in metallurgy, chemical, coal and refractory industries. This will make it easier and safer for your metal or other materials to store, transport and sell briquettes.

Roller assembly is the core part of briquetting machine. Particles are fed by squeezing them between two rollers rotating in opposite directions and then form final briquettes. It is composed of items such as main shaft, roller shell, bearing, bearing support and seals. Adopting high quality bearing steel, integral rollers are finished by multiply processes such as machining, UT, milling, hot treatment. After hot treatment, its surface hardness could be up to standard. All rollers are high wear-resisting and replaced easily. The main shaft is made of forging 40Cr, which is processed by multiple processes and processes such as drilling, turning, heat treatment and milling.

Roller shell and main shaft are assembled by an interference assembly, and then assembled into a roller assembly with corresponding seals such as bearings and bearing supports.

Oil cylinder constitutes of the cylinder body, piston, and seals. It is adopted high quality alloy steel piston, which is processed by many procedures such as machining, drilling, hot treatment, milling and so on. To prolong it service life, it is processed by chroming based on the original processes. The cylinder body is made of ZG45 and processed by multiple processes and processes such as turning, drilling and milling.

The screw is composed of a shaft, a flange and blades. The shaft is made of high-quality alloy steel, and the surface of blades is welded with a wear-resistant alloy layer, which is welded with shaft and flange. The wear-resistant alloy layer can be repeatedly deposited and reduced in cost.

The roller shell is made of high quality bearing steel and is processed by multiple processes such as turning, flaw detection, milling and heat treatment. The surface hardness can reach above HRC58.

Gear and gear shaft are very important parts of reducer. They are adopted hard-tooth surface,high quality alloy steel and are processed by turning, milling, drilling, hobbing,grinding,hot treatment and so on.

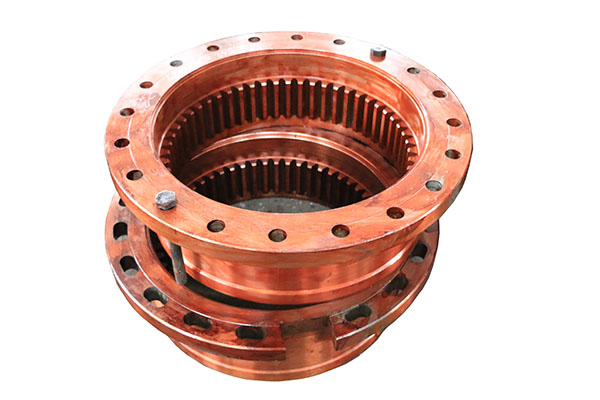

Internal ring gear and external gear shaft sleeve are adopted high quality alloy steel and processed by turning, milling, drilling, hobbing,grinding,hot treatment and so on.

Shaft is one of the main parts of mechanical products.It is made of forging 40Cr and is processed by multiple procedures such as turning, flaw detection, milling and heat treatment.

The bearing support is made of high-quality alloy steel, which is processed by multiple procedures such as turning, flaw detection, milling and so on.

MODEL |

GY1000-800 |

GY1200-1000 |

Unit |

| Roller Dia. | 1000 | 1200 | mm |

| Nominal Roller Width | 420 | 420 | mm |

| Max.Line Specific Pressure | 20-25 | 20-25 | t/cm |

| Total Pressure | 800 | 1000 | T |

| Main Motor Power | 280 | 560 | KW |

| Pre-Pressing Motor Power | 22×2 | 22×2 | KW |

| Hydraulic Motor Power | 5.5 | 5.5 | KW |

| Weight | 71000 | 106000 | Kg |

Model |

Roller dia.(mm) |

Roller width(mm) |

Total

pressure

|

Max. line

specific

|

Main motorpower(kw) |

Capacity(t/h) |

Weight(t) |

| GY520-150 | 520 | 196 | 150 | 8 | 55 | 2.2-3.5 | 13.7 |

| GY650-220 | 650 | 205 | 220 | 11 | 90 | 4-6.5 | 19.2 |

| GY750-200 | 750 | 320 | 200 | 6 | 110 | 7-10 | 24.5 |

| GY750-300 | 750 | 280 | 300 | 11 | 185 | 6-8.5 | 34 |

| GY800-380 | 800 | 350 | 380 | 11 | 200 | 8-10 | 39.3 |

| GY1000-350 | 1000 | 460 | 350 | 8 | 250 | 10-15 | 50 |

| GY1000-450 | 1000 | 500 | 450 | 9 | 280 | 14-17 | 58.5 |

| GY1000-500 | 1000 | 500 | 500 | 10 | 315 | 15-20 | 58.5 |

| GY1000-500 | 1000 | 900 | 450 | 5 | 280 | 25-30 | 63 |

| GY1000-540 | 1000 | 900 | 540 | 6 | 185×2 | 30-35 | 59.3 |

| GY1200-800 | 1200 | 900 | 800 | 8 | 280×2 | 40 | 110 |

| GY1400-1000 | 1400 | 1000 | 1000 | 10 | 355×2 | 50 | 156 |

Model |

Roller dia.(mm) |

Rollerwidth(mm) |

Totalpressure(t) |

Max. line

specific

|

Power(kw) |

Capacity(t/h) |

Weight(t) |

| ZY520-100 | 520 | 400 | 100 | 2.5 | 37 | 5-8 | 8.9 |

| ZY650-120 | 650 | 500 | 120 | 2.5 | 45 | 10-15 | 12.8 |

| ZY750-150 | 750 | 480 | 150 | 3 | 75 | 15-20 | 17.2 |

| ZY1000-300 | 1000 | 900 | 300 | 3 | 200 | 30-35 | 42 |

| ZY1200-300 | 1200 | 1000 | 300 | 3 | 250 | 45-50 | 78 |

| ZY1400-360 | 1400 | 1200 | 360 | 3 | 355 | 75-80 | 115 |

The application field of briquetting machine is very extensive. From the perspective of large industry, it includes refractory industry, metallurgical industry, chemical industry and coal industry. There are dozens of subdivided material types in each industry. If you want to find the corresponding material type, you can check it in the briquetting industry application solution.

The price range of the briquetting machine is relatively large. Due to the different production tonnage, the price of the large output is naturally higher. Generally, it is in USD30000-50000/set (reference price). For the specific price, please contact us for the best offer. In addition to these, there are some factors that will affect the price of the high pressure ball press.

1, special features

Many companies can make customized ball presses according to customer requirements for the molding of special materials. In this case, the price will be higher than the ordinary ball machine price.

2, steel prices

The high-pressure ball press is made of steel, and the parts such as the reducer used on the main machine are also in the steel production industry. Therefore, the price of raw materials such as steel is a direct factor affecting the price of the press machine.

3, manufacturers production mode

The pressure ball machine is supplied by the manufacturer in large-scale mass production. The equipment is manufactured in the form of a line for the processing of multiple machines. The cost will naturally drop. The price of the ball press equipment is lower than that of some non-professional mass production. The manufacturer is low.

We hope that you can view pictures and videos about the briquetting press in more detail in our product section. At the same time, we are also willing to show you the high-definition pictures of several ball presses.

Add: Luoxin Industrial Zone,Luoyang City,Henan Province P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com

Official Agent of ZY MINING in Russia.

Please enter here.

Add: Luoxin Industrial Zone,Luoyang City,Henan Province P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com