-

Products

-

Application

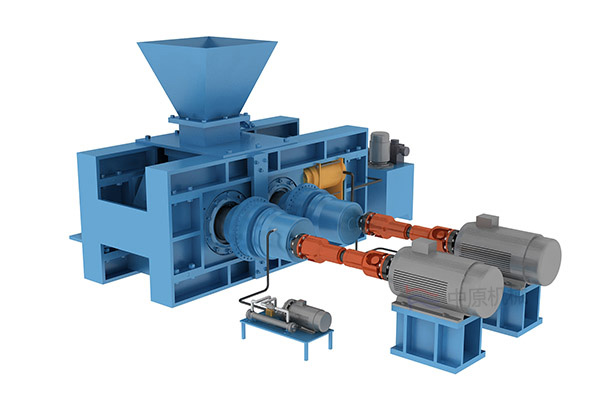

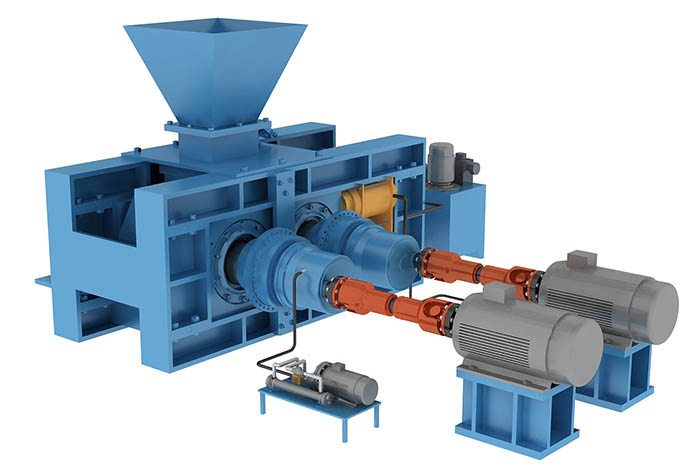

The high-pressure roller mill is very popular in today’s major mining companies. The reason cannot be separated from its efficiency and energy saving. For some small partners who have not yet purchased, the high-pressure roller mill is still a relatively unfamiliar crushing equipment, so When purchasing, it is not clear what kind of power equipment you want, so the high-pressure roller mill manufacturer is here to help you select the high-pressure roller mill, and hope that everyone can choose the right equipment.

The high-pressure roller mill has a good crushing effect and strong processing capacity, which can greatly improve the processing capacity of the ball mill. It has high energy-saving effects and considerable economic benefits. It is suitable for crushing and grinding a variety of metal ores, non-metal ores, pellets, steel slag, etc. Operations can bring many improvements to various production systems:

1. After the crushing system is added to the high-pressure roller mill, the particle size of the fine crushed cone discharge can be doubled, which can increase the production capacity and reduce the energy consumption of the crushing;

2. After the grinding system is added to the high-pressure roller mill, the particle size of the ball mill is greatly reduced. While increasing energy and reducing consumption, the broken minerals are microscopically cracked along the crystal lattice direction, thereby improving the grinding efficiency and benefiting Later selection of minerals;

3. The production process of the high-pressure roller mill enables the material to achieve "more crushing and less grinding", which can reach the ultra-fine particle size of less than 3 mm.

The selection of the high-pressure roller mill is mainly determined by the unit processing capacity of the equipment, motor power, roll gap and roll surface life. These data are different for equipment of different specifications:

According to different feeding particle size, ore hardness, ore density and product size requirements, the unit processing capacity of the same high-pressure roller mill is also different. If you want to choose equipment with higher processing capacity, you need to have the requirements for materials and products. I have a deep understanding that under normal circumstances, the density of the cake is about 85% of the density of the ore. The factors that affect the unit processing capacity of the high-pressure roller mill are:

(1) Diameter of pressure roller of high pressure roller mill;

(2) Width of pressure roller of high pressure roller mill;

(3) The linear velocity of the pressure roller of the high-pressure roller mill, etc.

The motor power of the high-pressure roller mill does not correspond to its specifications and models. It is usually calculated and determined by the tested unit power consumption. The power of a single motor should be 0.69 high-pressure roller mill unit processing capacity multiplied by unit power consumption. Some small partners choose to choose a larger motor, which causes energy waste.

Roll gap and roll surface are also one of the factors in the selection of high-pressure roller mills. A reasonable roll gap should be between 2.8% and 3.0% of the roll surface diameter, and the feed size should not exceed the width of the roll gap; Under normal circumstances, the width of the side material is twice the reasonable roll gap, and the smaller the occupancy rate of the side material, the better the rolling effect. Therefore, as far as possible, choose a device with a wider roll surface while ensuring the performance of the equipment.

The roller surface material is an important factor in determining the life of the roller surface. Therefore, when selecting a high-pressure roller mill, you must understand what the material used on the roller surface is. At the same time, it is recommended to select a linear speed equivalent to the diameter of the roller surface. The upper guarantees the life of the roller surface.

Based on the above selection factors, it can be seen that the larger the size of the high-pressure roller mill, the better. Due to the different feed size, it is not a good choice to choose a larger size high-pressure roller mill. Therefore, it is recommended to ensure that the When the throughput is satisfied, choose a model with a smaller roll surface diameter as much as possible. The advantages of doing so are:

(1) The roll diameter is small and the roll width is large, which can reduce the influence of the boundary effect on the crushing effect;

(2) Reduce the weight of the whole machine, reduce the tonnage of the plant, and reduce the investment in civil construction;

(3) Reduce the inventory value of spare parts;

(4) Conventional spare parts can be exchanged and deployed to effectively ensure the stability of the system.

1. The system pressure should be determined according to the nature of the crushed minerals by the high-pressure roller mill and the qualified particle size to be crushed. When meeting the crushing particle size requirements of the production, the smaller the roller surface pressure, the better. If the pressure on the roller surface is large, the energy consumption will be large, the wear of the roller surface will be aggravated, and the economic cost will increase. At the same time, the crushing effect does not increase linearly with the increase of the roller surface pressure. When the material is crushed to a certain extent, the roller surface pressure increases, and the crushing effect almost changes little.

2. At present, there are mainly three types of roll surface on the market: surfacing roll surface, alloy roll surface and stud roll surface. It can be selected according to different material properties. In addition to quality and linear speed, everyone should pay attention to the particle size of the feed when using it. If the feed size is too hard and wear-resistant, it will easily wear the roll surface. At the same time, pay attention to prevent the entry of metal objects, and directly Damage to the roll surface.

3. The moisture content of the material will affect the establishment of the pressure chamber of the high-pressure roller mill. If the moisture content of the material is large, it is difficult to form a material cushion, and the roller surface matrix will wear out quickly without the material cushion. But at the same time, the material cannot be completely water-free, especially when the grinding particle size is relatively small (less than 1 mm), the dried material is prone to pulse-like vibration, which has a great impact on the entire high-pressure roller mill. Under normal circumstances, the moisture content of the material should be controlled between 1.5% and 8%.

The above is all the content of the high-pressure roller mill selection suggestions, which are the methods we summarized through other documents and test results. I hope it can be helpful to everyone.

Official Agent of ZY MINING in Russia.

Please enter here.

Add: Luoxin Industrial Zone,Luoyang City,Henan Province P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com