-

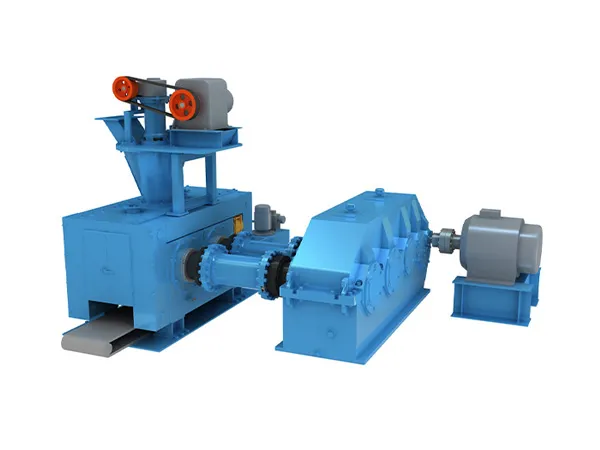

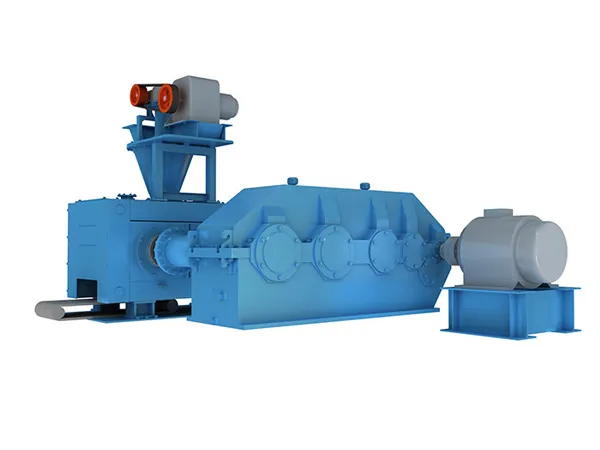

Products

-

Application

A ball press machine, more commonly known as a briquetting machine or briquetter, is used to compress powdery or granular materials into solid, uniform shapes (briquettes), often resembling balls, pillows, ovals, or squares. This process offers several advantages like improved handling, storage, transportation, and utilization of fine materials.

Steelmaking: Briquetting iron ore fines, mill scale, converter dust, flue dust, and other iron-bearing materials for charging into blast furnaces or direct reduction plants. This recovers valuable materials and improves furnace operation.

Ferroalloy Production: Briquetting fines of manganese ore, chrome ore, nickel ore, etc., for smelting furnaces.

Non-Ferrous Metals: Briquetting dusts and fines from copper, zinc, lead, and aluminum processing for recycling and smelting.

Lime and Dolomite: Briquetting quicklime or dolomite fines for use as flux in steelmaking, reducing dust and improving handling.

Coal Briquetting: Compressing coal fines or dust into briquettes for industrial boilers, gasifiers, or domestic heating. This utilizes low-grade coal fines and reduces waste.

Coke Briquetting: Briquetting coke breeze (fine coke particles) for use in foundries or blast furnaces, recovering valuable fuel/reductant.

Charcoal Briquetting: Compressing charcoal powder (often with a binder) into briquettes for barbecue, industrial heating, or activated carbon production.

Fertilizers: While granulation is common, briquetting can sometimes be used for specific fertilizer materials or formulations to reduce dust and improve handling.

Salt Briquetting: Producing salt blocks or briquettes for animal licks or industrial applications.

Mineral Processing: Briquetting various mineral fines (e.g., fluorite, magnesite, bauxite) for easier handling, transportation, or feeding into subsequent processes like kilns or furnaces.

Refractory Materials: Briquetting fine refractory powders before firing.

Flue Gas Desulfurization (FGD) Gypsum: Briquetting FGD gypsum powder, a byproduct of coal-fired power plants, for easier handling and potential use in construction materials (e.g., cement production).

Industrial Dusts & Sludges: Compressing various industrial dusts (e.g., from filters) or dried sludges into briquettes for safe disposal, easier handling, or potential material recovery. This reduces dust hazards and transport volume.

Mining Tailings: Potentially briquetting certain types of dewatered mine tailings for easier management or backfilling (depending on material properties and binder usage).

In summary, the primary applications revolve around:

Agglomerating fines: Turning dusty, difficult-to-handle powders into solid lumps.

Waste recovery: Utilizing byproducts and waste fines.

Improving process efficiency: Providing uniformly sized feed material for furnaces, kilns, or reactors.

Enhancing logistics: Reducing dust, increasing bulk density, and simplifying storage and transport.

The specific material often requires a binder (like molasses, starch, lime, cement, or specialized chemicals) to ensure the briquettes have sufficient strength after pressing. The choice of binder depends on the material and the end-use of the briquette.

Add: Luoxin Industrial Zone,Luoyang City,Henan Province P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com

Official Agent of ZY MINING in Russia.

Please enter here.

Add: Luoxin Industrial Zone,Luoyang City,Henan Province P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com