-

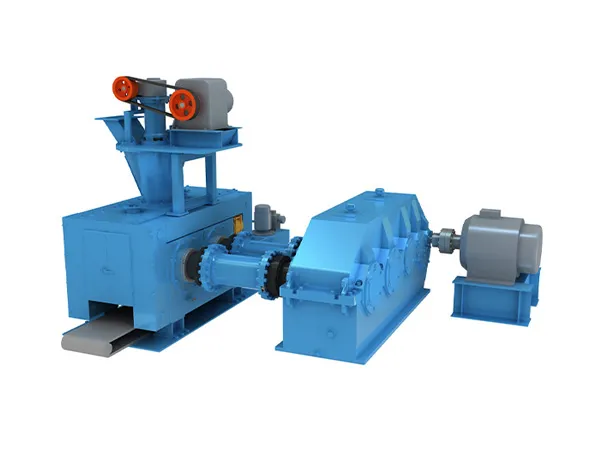

Products

-

Application

Briquetting machines are essential in compressing various raw materials into compact, manageable briquettes for easier storage, transportation, and usage. However, one common operational challenge is machine jamming. A jammed briquetting machine can disrupt production, cause equipment damage, and increase maintenance costs. Understanding the root causes of jamming, the warning signs, and effective prevention strategies is crucial for maintaining smooth and efficient briquetting operations.

Stop the Machine: Immediately turn off the power to the briquette machine. Do not attempt to clear the jam while the machine is running.

Disconnect Power: For added safety, unplug the machine from its power source. This prevents any accidental start-up during the clearing process.

Wait for it to Stop Completely: Ensure all moving parts have come to a complete standstill before attempting to intervene.

Carefully inspect the machine to understand why it has jammed. Common causes include:

Material Blockage:

Oversized Material: Pieces of raw material that are too large to pass through the machine.

Foreign Objects: Rocks, metal pieces, or other debris mixed in with the raw material.

Wet or Sticky Material: Material with excessive moisture content or a sticky consistency can clump and cause blockages.

Inconsistent Material Size: A wide range of particle sizes can sometimes lead to bridging and jams.

Machine Issues:

Worn or Damaged Parts: A worn die, screw conveyor, or other internal components can impede material flow.

Improper Temperature: If the machine uses heat, incorrect temperature settings can affect material flow and cause sticking.

Insufficient Lubrication: Lack of lubrication can increase friction and lead to jams.

Overfeeding: Trying to process too much material at once can overload the machine.

Refer to Your Machine's Manual: Your briquette machine's manual should provide specific instructions on how to clear jams and troubleshoot common issues. Always prioritize the manufacturer's recommendations.

Manual Removal:

Open Access Points: If your machine has access panels or doors, open them to get a better view of the blockage.

Use Tools: Employ appropriate tools to carefully dislodge the jammed material. This might include:

Sturdy Stick or Rod: To gently push material through.

Pliers or Tongs: To grab and remove larger obstructions.

Brush: To clear away loose material and debris.

Avoid Force: Do not use excessive force that could damage the machine's components. Work patiently to loosen and remove the blockage.

Reverse Operation (If Applicable and Safe): Some machines have a reverse function. If your manual indicates it's safe to do so, briefly running the machine in reverse after manually removing as much blockage as possible might help dislodge remaining material. However, do this cautiously and be prepared to stop immediately if it doesn't help or sounds strained.

Cleaning: Once the main blockage is cleared, thoroughly clean the affected areas to remove any residual material that could cause future jams.

To minimize future jams, consider these preventative measures:

Material Preparation:

Screening: Use a screen or sieve to remove oversized particles and foreign objects from your raw material.

Drying: Ensure your raw material has the correct moisture content as recommended by the machine manufacturer. Use a dryer if necessary.

Consistent Feeding: Feed material into the machine at a steady and appropriate rate. Avoid overloading.

Regular Maintenance:

Lubrication: Follow the manufacturer's lubrication schedule.

Inspection: Regularly inspect the machine for wear and tear on critical components. Replace worn parts promptly.

Cleaning: Clean the machine regularly to prevent material buildup.

Temperature Control: If your machine uses heat, ensure the temperature settings are correct for the material you are processing.

If you cannot clear the jam safely or if the machine continues to jam frequently, it's best to contact the manufacturer or a qualified technician. There might be an underlying mechanical issue that requires professional attention.

By following these steps, you can safely and effectively address briquette machine jams and implement preventative measures to ensure smoother operation in the future.

Add: Luoxin Industrial Zone,Luoyang City,Henan Province P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com

Official Agent of ZY MINING in Russia.

Please enter here.

Add: Luoxin Industrial Zone,Luoyang City,Henan Province P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com