-

Products

-

Application

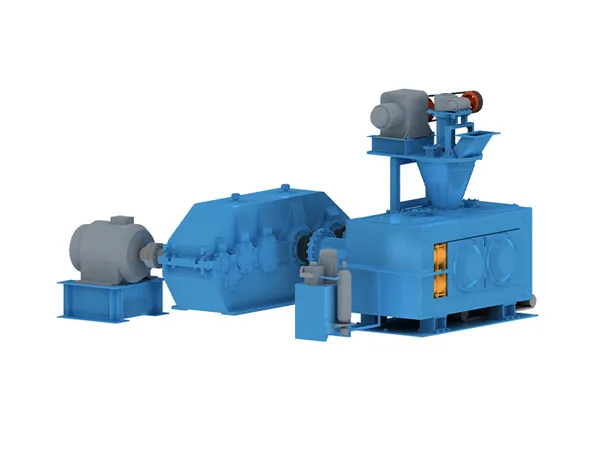

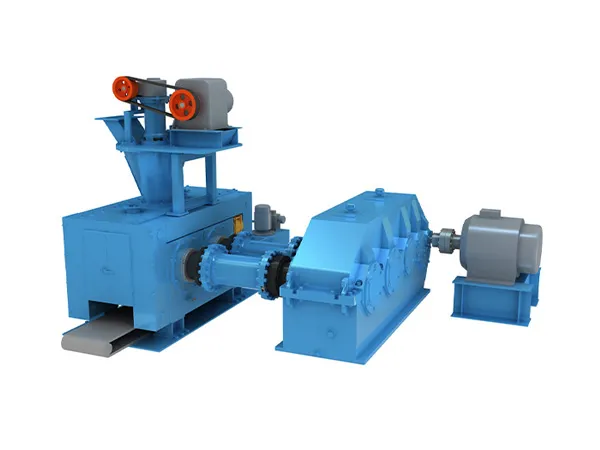

A ball press machine, also known as a briquette press or pellet press, is a type of mechanical equipment that presses powdery or granular materials into spherical or cylindrical shapes. These machines are often used to create briquettes or pellets for various applications, including fuel production, metallurgy, chemical processing, and more. There are different types of ball press machines, each designed for specific materials and purposes.

This type of ball press machine uses two counter-rotating rollers to compact the material into the desired shape. The material is fed between the rollers, and the pressure applied by the rollers forms the material into balls or other shapes.

Hydraulic ball press machines use hydraulic cylinders to apply pressure to the material, compacting it into the desired form. These machines are capable of exerting high pressure, making them suitable for processing materials that require intense compression.

Mechanical ball press machines utilize mechanical systems, such as gears and cams, to generate the force needed to press the material into shape. These machines may have a simpler design compared to hydraulic systems.

Screw press machines use a screw mechanism to compact materials. The material is fed into a chamber, and as the screw rotates, it pushes the material forward, applying pressure and forming it into the desired shape.

Piston press machines use a piston to apply pressure to the material. The piston is typically driven by a hydraulic or mechanical system, forcing the material into a specific mold or die to create the desired shape.

While not exclusively for ball-shaped products, tablet press machines can be adapted to produce small cylindrical or ball-shaped tablets. These machines are often used in pharmaceutical and chemical industries for tablet and pellet production.

Pressing Mechanism

Ball press machines often use a system of rollers, hydraulic cylinders, or mechanical presses to apply pressure to the material and compact it.

Die or Mold

The die or mold is a critical component that shapes the compressed material into the desired form, whether it's cylindrical briquettes or other shapes.

Hopper and Feeding System

The hopper is where the raw material is loaded into the machine. Some machines have a built-in feeding system or conveyors to automate the material feeding process.

Pressure Control

Modern ball press machines may have pressure control systems to adjust the level of compression based on the type of material being processed.

Cooling System (optional)

In some applications, a cooling system is integrated to cool down the freshly pressed briquettes or pellets, preventing them from sticking together.

Material Preparation

The material to be processed is typically in the form of powder, dust, fines, or small particles. This material can be various types of biomass, coal, charcoal, metal powder, mineral powder, or other similar substances.

Material Feeding

The raw material is fed into the hopper of the ball press machine. This can be done manually or using a conveyor system, depending on the design and capacity of the machine.

Compression and Pressing

Inside the machine, there is a pressing chamber where the raw material is subjected to high pressure. A pressing mechanism, often involving rollers or hydraulic cylinders, compresses the material into a dense and compact form.

Formation of Briquettes or Pellets

The compressed material takes the shape of briquettes or pellets, depending on the specific design of the ball press machine. The compacted material is forced through a die or mold that shapes it into the desired form.

Ejection

The formed briquettes or pellets are then ejected from the machine. This can be done manually or automatically, depending on the machine's features.

Capacity: The capacity of the ball press machine, usually measured in terms of output per hour, significantly influences its cost. Machines with higher capacities typically come with higher price tags.

Automation Level: The level of automation can range from manual operation to semi-automatic or fully automatic systems. More automated machines tend to be more expensive due to the advanced features and technologies incorporated.

Material Compatibility: The type of materials the ball press machine can process can impact its cost. Some machines are designed for specific materials, while others are more versatile and can handle a variety of materials.

Brand and Manufacturer: Different manufacturers offer ball press machines with varying quality and features. Well-established and reputable brands may have higher prices, but they often come with better reliability and performance.

Market Conditions: Local market conditions and demand for such machines can influence their prices. Prices may vary based on the availability of similar machines in the market and competition among manufacturers.

Additional Features: Some ball press machines come with additional features such as advanced control systems, safety features, or customization options. These features can contribute to a higher overall cost.

Energy Efficiency: Energy-efficient machines may have a higher upfront cost, but they can result in long-term cost savings through reduced energy consumption.

Material Type

Different machines are designed for specific materials, such as coal, charcoal, metal powders, or biomass. Choose a machine that is suitable for the material you intend to process.

Production Capacity

Consider the required production capacity of the machine. Different machines have varying output capacities, and selecting the right one depends on your production needs.

Pressure Requirements

Depending on the material, some applications may require higher pressure for effective compaction. Hydraulic presses are known for their ability to exert high pressure.

Automation and Control

Some machines come with advanced automation and control features, allowing for precise adjustment of parameters and ease of operation.

Cost and Maintenance

Consider the initial cost of the machine as well as ongoing maintenance requirements. Choose a machine that fits your budget and is practical for your maintenance capabilities.

Biomass Briquetting: Convert agricultural and forestry waste into compact and energy-dense briquettes for use as fuel.

Metal Powder Compaction: Form metal powders into briquettes or pellets for recycling or transportation.

Mineral Powder Briquetting: Create briquettes from mineral powders for various industrial applications.

Coal and Charcoal Briquetting: Produce briquettes from coal and charcoal fines for use in heating or industrial processes.

The above is the complete introduction about the cost of briquetting machine.When selecting a ball press machine, it's essential to understand the specific requirements of your application and choose a machine that meets those needs efficiently and effectively.

More information about briquetting machines:

How to choose a briquetting machine

A Guide to Briquetting Machines: Types, Processes and Uses

What are the types of ball press machine

What is the price of the ball press machine

What is the working principle of the ball press machine

Add: Luoxin Industrial Zone,Luoyang City,Henan Province P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com

Official Agent of ZY MINING in Russia.

Please enter here.

Add: Luoxin Industrial Zone,Luoyang City,Henan Province P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com