-

Products

-

Application

A briquetting machine, also known as a briquette press or briquette maker, is a device that uses pressure to turn various forms of loose raw materials, such as biomass, wood shavings, sawdust, and agricultural residues, into high-density, compacted, and consistent-shaped briquettes. These briquettes can serve as a renewable and efficient energy source or as a raw material for various industrial processes.

For more details about the briquetting machine meaning, please visit:Briquetting Machine meaning, use, price, picture

Screw Extruder Briquetting Machines:

Working Principle: These machines use a screw to compress the material through a tapered die.

Hydraulic Briquetting Machines:

Working Principle: Hydraulic systems generate high pressure to compress materials in a hydraulic cylinder.

Mechanical Press Briquetting Machines:

Working Principle: Operate using a mechanical eccentric action to compress materials.

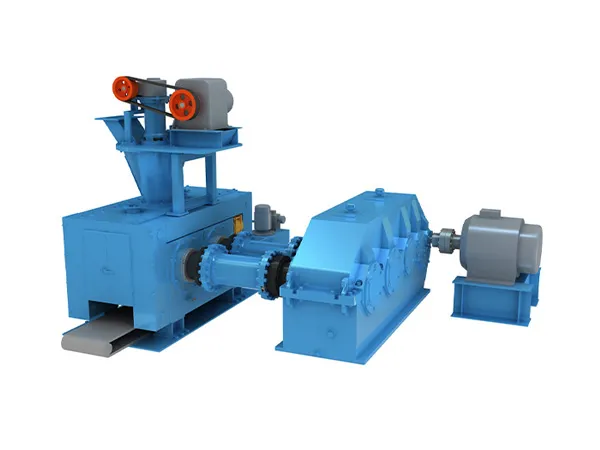

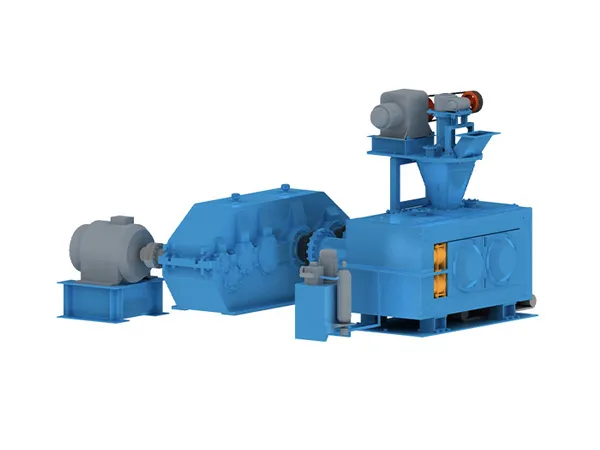

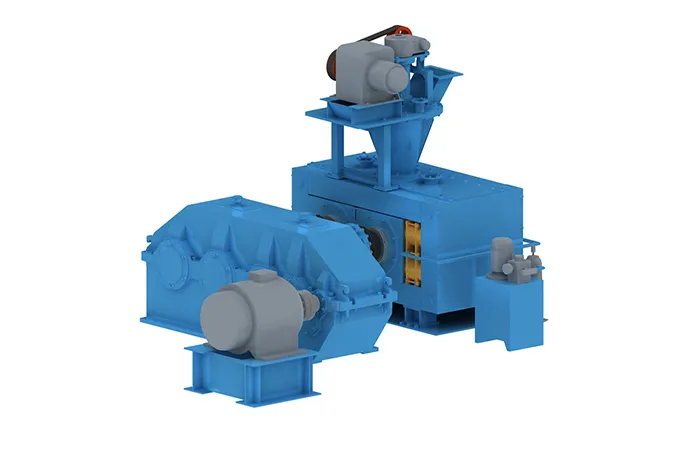

Roller Press Briquetting Machines:

Working Principle: Two counter-rotating rollers compact the material into briquettes.

Piston Press Briquetting Machines:

Working Principle: A reciprocating piston compresses the material in a closed chamber.

Screw Press Briquetting Machines:

Working Principle: Similar to screw extruders, these machines use a screw to push the material through a die.

Punching Briquetting Machines:

Working Principle: Use a punching mechanism to compact the material in a closed die.

Heat Press Briquetting Machines:

Working Principle: Utilize heat to soften the material before compacting it.

Material Preparation:

Raw Material Selection: Choose appropriate raw materials such as biomass residues (sawdust, crop straw, etc.), industrial by-products, or other suitable materials.

Size Reduction: Grind or chop the raw materials to reduce their size, facilitating the briquetting process.

Drying (Optional):

Moisture Content Reduction: If the raw materials contain excess moisture, drying may be necessary to achieve the desired moisture content. This step improves the efficiency of the briquetting process.

Briquette Formulation:

Binder Addition (Optional): Depending on the nature of the raw materials, binders may be added to enhance the cohesion of the briquettes. Common binders include starch, molasses, or lignin.

Briquetting Machine:

Selection of Briquetting Equipment: Choose a suitable briquetting machine based on the characteristics of the raw materials and the desired briquette shape and size. Common types of briquetting machines include mechanical presses, hydraulic presses, and screw presses.

Briquetting Process:

Feeding: Load the prepared raw material into the briquetting machine's hopper.

Compression: Apply pressure to the raw material using the machine's mechanisms. This can involve a combination of mechanical force, hydraulic pressure, or screw action, depending on the type of machine.

Compaction: The material undergoes compaction and forms into a dense, solid briquette.

Ejection: The formed briquettes are then ejected from the machine.

Cooling (Optional):

Cooling the Briquettes: Some briquettes may undergo a cooling process to stabilize their structure and improve their handling characteristics.

Packaging and Storage:

Packaging: Once the briquettes have cooled (if cooling is required), they are packaged for storage or transportation.

Storage: Store the briquettes in a dry environment to prevent deterioration.

Utilization:

Energy Generation: Briquettes can be used as a fuel source for heating, cooking, or generating electricity.

Industrial Applications: Some briquettes find use as a raw material substitute in various industrial processes.

Renewable Energy Production:

Briquettes can be made from biomass materials such as wood chips, sawdust, agricultural residues, and other organic wastes.

The briquettes serve as a renewable and cleaner alternative to traditional fossil fuels like coal.

Used in heating applications, such as in boilers, stoves, and industrial furnaces.

Waste Recycling:

Briquetting machines can process various types of waste materials, including paper, cardboard, plastics, and metal scraps.

Recycling waste into briquettes reduces the volume of waste and facilitates easier handling, storage, and transportation.

Metal Recycling:

Metal briquettes are formed from metal chips, turnings, or swarf generated in metalworking processes.

Briquetting metal waste improves its recyclability and reduces the environmental impact of metal production.

Agricultural Residue Utilization:

Crop residues like rice husk, straw, and other agricultural by-products can be briquetted.

Briquettes made from agricultural residues are used as a clean and sustainable fuel source in rural areas.

Brick Manufacturing:

Briquettes made from coal dust or other carbonaceous materials are used as a fuel in brick kilns.

This application helps in reducing the environmental impact associated with traditional brick manufacturing processes.

Chemical Industry:

Briquettes can be used as a raw material or fuel in certain chemical processes.

Some chemical processes require specific types of briquettes with controlled properties.

Hollow Briquettes for Charcoal Production:

Briquetting machines can produce hollow briquettes suitable for use in charcoal production.

These briquettes are often used in cooking and heating applications.

Emission Reduction in Industrial Processes:

Briquettes can replace traditional raw materials or fuels in industrial processes, reducing emissions and improving sustainability.

Domestic Heating:

Briquettes are used as a fuel source in household stoves, fireplaces, and heating appliances.

They provide a convenient and efficient way to utilize biomass or other suitable materials for heating.

Landscaping and Agriculture:

Briquettes made from organic materials can be used as soil conditioners or fertilizers, promoting sustainable agricultural practices.

Type of Raw Material:

Identify the type of material you intend to briquette. Different briquetting machines are designed to handle specific types of raw materials such as biomass, metal, or other industrial by-products.

Briquette Size and Shape:

Determine the desired size and shape of the briquettes. Different machines offer various options for the shape and size of the final product, and your choice will depend on the application and specifications of the end-user.

Production Capacity:

Assess your production requirements in terms of the volume of briquettes needed per hour or day. Choose a machine with the appropriate capacity to meet your production goals.

Energy Efficiency:

Consider the energy efficiency of the briquetting machine. Look for features such as efficient motors, heating systems, and overall energy consumption to minimize operational costs.

Automation and Control Systems:

Evaluate the level of automation and the control system of the machine. Advanced control systems can enhance productivity and help maintain consistent quality in the briquettes produced.

Maintenance and Durability:

Assess the maintenance requirements of the machine. Look for a machine that is easy to maintain, and check the durability of key components to ensure a longer lifespan.

Cost and Budget:

Consider your budget constraints and compare the costs of different machines. Take into account not only the initial purchase price but also ongoing operational costs and potential maintenance expenses.

Compatibility with Additives:

If your raw material requires additives such as binders or lubricants, ensure that the chosen briquetting machine is compatible with these substances.

Local Support and Service:

Check the availability of local technical support and service for the chosen machine. Having access to reliable support can be crucial for troubleshooting and maintenance.

Environmental Impact:

Consider the environmental impact of the briquetting process. Some machines may have features or technologies that contribute to a more environmentally friendly operation.

Testing and Trial Runs:

Whenever possible, conduct tests or trial runs with the machine using your specific raw material. This helps to verify its performance and suitability for your application.

References and Reviews:

Seek references from other users or read reviews about the performance and reliability of the briquetting machine from reputable sources or existing customers.

Luoyang Zhongyuan Mining Machine Manufacture Co., Ltd.,covers an area of 30,000 square meters. With more than 50 sets of processing equipment, we can complete the manufacturing and production of various large and medium-sized crushing, grinding and briquetting equipment, and has a complete detection system. The total assembly lifting capacity is up to 40T. It can meet the selection, design and manufacturing requirements of different customers. Looking forward to your consultation.

Add: Luoxin Industrial Zone,Luoyang City,Henan Province P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com

Official Agent of ZY MINING in Russia.

Please enter here.

Add: Luoxin Industrial Zone,Luoyang City,Henan Province P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com