-

Products

-

Application

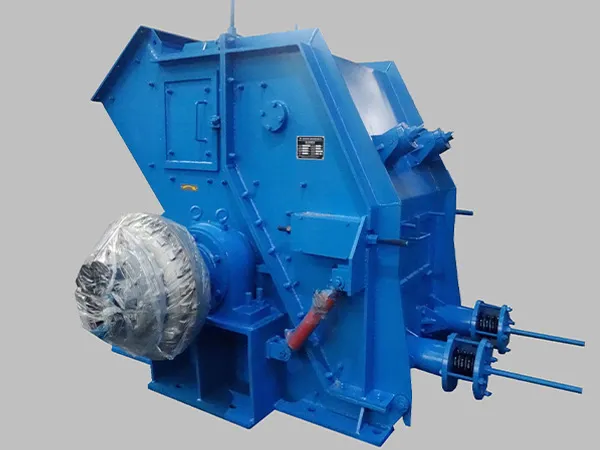

A compound crusher is a type of crusher that combines multiple functions into one unit. It is commonly used in the crushing production line for various hard and brittle materials, such as rock, ore, blockages, and building aggregates. The compound crusher typically includes a combination of crushers, screens, conveyors, and other equipment to facilitate the crushing process.

The design of a compound crusher allows it to perform multiple stages of crushing within a single machine. This can include primary, secondary, and even tertiary crushing processes. The compound crusher is often used in the production of artificial sand and is suitable for processing materials with high moisture content and other challenging characteristics.

One common type of compound crusher is the vertical shaft impact crusher (VSI), which uses a high-speed rotor to throw materials against the crushing chamber's walls, breaking them into smaller pieces. Other designs may involve combinations of different types of crushers to achieve the desired crushing outcomes.

Compound crushers are employed in various industries, including mining, construction, and aggregate production, where the goal is to produce a well-graded and shaped final product efficiently.

High Crushing Efficiency: The compound crusher combines the advantages of the hammer crusher and the impact crusher. It has high crushing efficiency and is capable of crushing large materials into smaller particles.

Adjustable Discharge Size: The discharge size of the compound crusher can be adjusted by changing the gap between the impact plate and the rotor. This flexibility allows for the production of various sizes of crushed materials.

Low Maintenance: The design of the compound crusher is relatively simple, resulting in low maintenance requirements. This makes it a cost-effective option for many industries.

Wide Range of Applications: Compound crushers are suitable for crushing various materials, including coal, clinker, gypsum, limestone, and other materials with medium to high hardness.

Main Frame: The main frame provides structural support for the entire crusher.

Rotor: The rotor is the main working component of the compound crusher. It is equipped with a series of hammers or impact plates that strike the material during the crushing process.

Impact Plate: The impact plate is a crucial component that absorbs the impact energy generated during the crushing process. It plays a role in breaking down the materials into smaller particles.

Adjusting Device: The adjusting device allows for the adjustment of the gap between the impact plate and the rotor, controlling the size of the crushed material.

Transmission System: The compound crusher is typically powered by an electric motor that drives the rotor through a belt or a chain.

The material is fed into the upper part of the compound crusher through the feeding hopper.

The rotor, equipped with hammers or impact plates, starts rotating at high speed.

The material is subjected to the high-speed impact and crushing forces generated by the rotating rotor and impact plates.

Crushed material is discharged through the bottom of the crusher after reaching the desired size.

Compound crushers are widely used in various industries for crushing materials such as:

Mining: Crushing of ores and minerals.

Cement Industry: Crushing of clinker and raw materials.

Building Materials: Crushing of limestone, gypsum, and other building materials.

Chemical Industry: Reduction of chemical raw materials.

Metallurgy: Crushing of various metallurgical ores.

In conclusion, the compound crusher is a versatile and efficient crushing machine used in multiple industries for reducing the size of materials. Its ability to handle a wide range of materials and its adjustable discharge size make it a valuable asset in the production process.

More information about compound crusher:

What are the factors that affect the price of compound crusher?

How does a compound cone crusher work?

What is the internal structure of the compound crusher?

Repair and maintenance methods of compound crusher

Detailed explanation of compound crusher

What are the advantages of vertical compound crusher?

Add: Luoxin Industrial Zone,Luoyang City,Henan Province P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com

Official Agent of ZY MINING in Russia.

Please enter here.

Add: Luoxin Industrial Zone,Luoyang City,Henan Province P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com