-

Products

-

Application

In the phosphate industry, achieving high grinding efficiency while controlling operational costs is crucial for maximizing profitability. High-pressure grinding rolls (HPGR) have emerged as a revolutionary technology, offering significant advantages over traditional grinding methods such as ball mills.

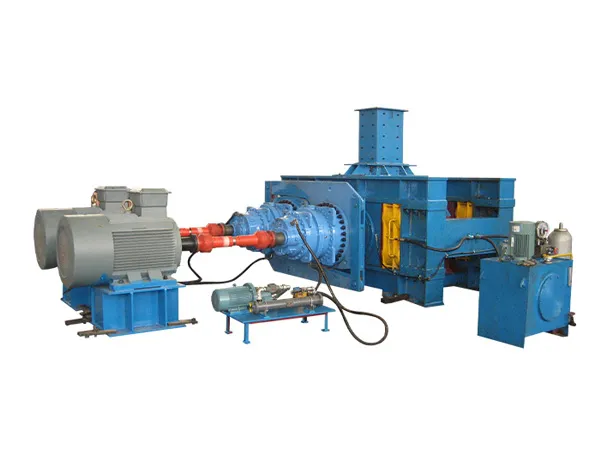

HPGR systems use intense compressive forces to crush phosphate rocks between two counter-rotating rolls. This process generates a unique micro-fracturing effect, which produces finer particles and enhances the liberation of phosphate minerals. Compared to conventional grinding methods, HPGR can reduce energy consumption while maintaining—or even increasing—throughput.

By optimizing feed size and adjusting operating pressure, phosphate producers can achieve a more uniform particle size distribution. This improvement not only benefits downstream processes like flotation and chemical treatment but also reduces wear and tear on equipment, lowering maintenance costs over time.

The shift to HPGR is largely driven by its strong cost efficiency. Key financial benefits include:

Lower Energy Consumption: HPGR typically consumes 20–30% less energy than traditional ball mills, directly reducing electricity expenses.

Reduced Maintenance Costs: With fewer moving parts and less abrasive wear, HPGR systems require less frequent maintenance.

Higher Throughput: Enhanced grinding efficiency enables plants to process more material in less time, increasing overall production without substantial capital investment.

HPGR is not only cost-effective but also environmentally friendly. Reduced energy consumption leads to lower greenhouse gas emissions, while decreased use of grinding media minimizes waste. As sustainability becomes a priority in mining, adopting HPGR supports greener phosphate production and positions companies as environmentally responsible leaders in the sector.

To maximize the benefits of HPGR, phosphate producers should consider the following:

Proper Feed Preparation: Correct pre-grinding size ensures optimal HPGR performance.

Roll Surface Monitoring: Regular inspections and maintenance of roll surfaces maintain consistent efficiency.

Integration with Downstream Processes: Coordinating HPGR output with flotation, beneficiation, or chemical processing enhances overall plant productivity.

High-pressure grinding rolls are transforming phosphate production by combining superior grinding efficiency with cost-effective operations. By reducing energy consumption, improving mineral liberation, and lowering maintenance requirements, HPGR technology offers a strategic advantage for modern phosphate plants. Companies aiming to stay competitive should view HPGR as a smart investment for sustainable, high-performance operations.

Add: Luoxin Industrial Zone,Luoyang City,Henan Province P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com

Official Agent of ZY MINING in Russia.

Please enter here.

Add: Luoxin Industrial Zone,Luoyang City,Henan Province P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com