-

Products

-

Application

In modern mineral processing, choosing the right grinding technology is key to boosting productivity and cutting operational costs. Among the most widely used options are High Pressure Grinding Rolls (HPGR) and Ball Mills. But which one delivers better efficiency, higher throughput, and lower energy consumption?

Ball Mills have been the backbone of grinding technology for decades. They work by rotating a cylinder filled with steel balls, crushing ore through impact and attrition. Known for their versatility, ball mills are capable of grinding a wide range of materials, making them ideal for fine particle size production in ball mills.

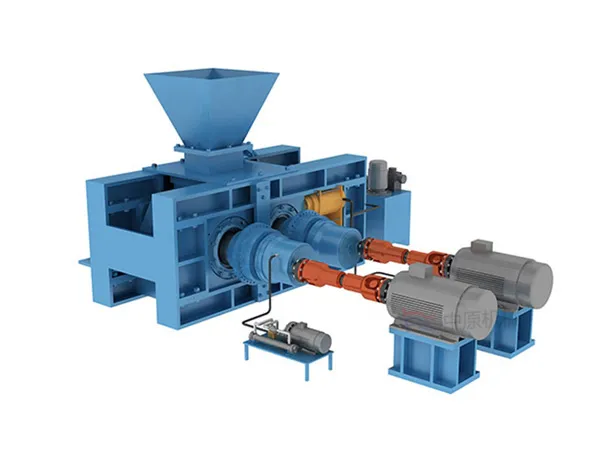

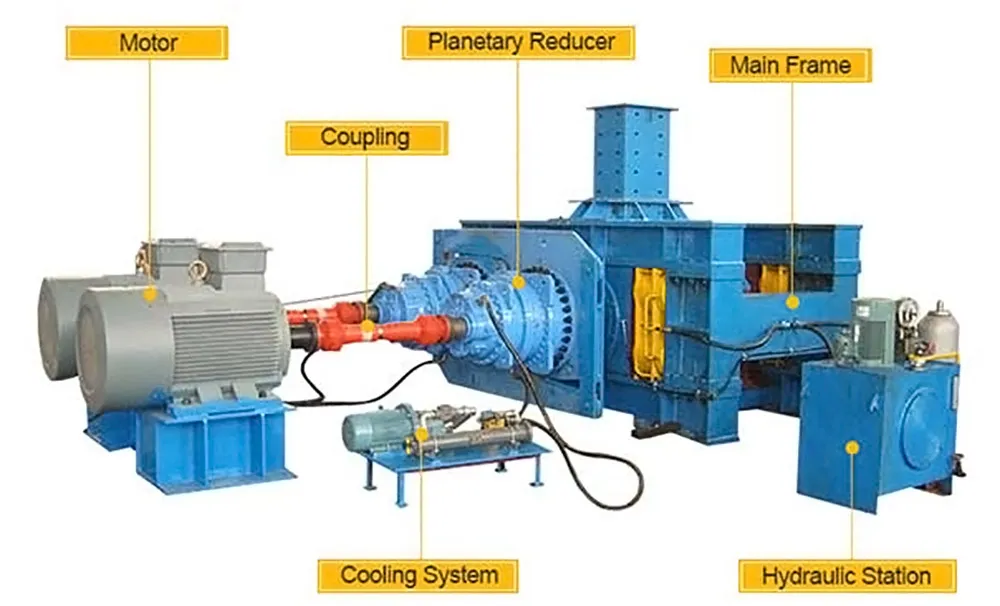

High Pressure Grinding Rolls (HPGR), on the other hand, use two counter-rotating rolls to compress ore under high pressure, creating micro-cracks that enhance downstream processes such as leaching and flotation. The advantages of HPGR in mining include more uniform particle size distribution, improved liberation of valuable minerals, and often higher throughput than ball mills.

Energy consumption is a critical factor in modern mineral grinding. Studies and industrial data show that HPGR energy efficiency for hard ores can reduce energy use by 30–40% compared to traditional ball mills. This translates into significant cost savings, making HPGRs an excellent choice for reducing energy costs in mineral grinding.

Ball mills excel in producing very fine particle sizes, which is crucial for certain metallurgical processes. However, HPGRs provide more uniform particle size distribution and improved mineral liberation. Their continuous operation and lower grinding pressure requirements allow for throughput optimization techniques that boost overall process efficiency.

Ball mills are mechanically simpler but require frequent maintenance, including liners and grinding media replacement. HPGRs, while initially more capital-intensive, typically have lower wear costs and reduced downtime thanks to their durable roll surfaces and efficient grinding mechanism. These features make HPGRs appealing for industrial applications of HPGR in mineral processing.

The choice between HPGR and ball mills depends on several factors: ore hardness, production scale, energy costs, and downstream processing requirements. For hard ores and large-scale operations, HPGRs often deliver superior efficiency and cost savings. Ball mills remain a reliable choice for applications requiring ultra-fine particle sizes, offering flexibility and proven performance.

Mining operators looking to optimize grinding circuits for maximum productivity should carefully analyze ore characteristics and process requirements to determine which technology suits their operation best.

Both HPGRs and ball mills have essential roles in modern mineral processing. However, when efficiency and cost-effectiveness are the top priorities, HPGR technology increasingly stands out. By leveraging HPGR vs Ball Mills efficiency comparison insights, mining companies can reduce energy consumption, improve throughput, and maximize profitability.

Add: Luoxin Industrial Zone,Luoyang City,Henan Province P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com

Official Agent of ZY MINING in Russia.

Please enter here.

Add: Luoxin Industrial Zone,Luoyang City,Henan Province P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com