-

Products

-

Application

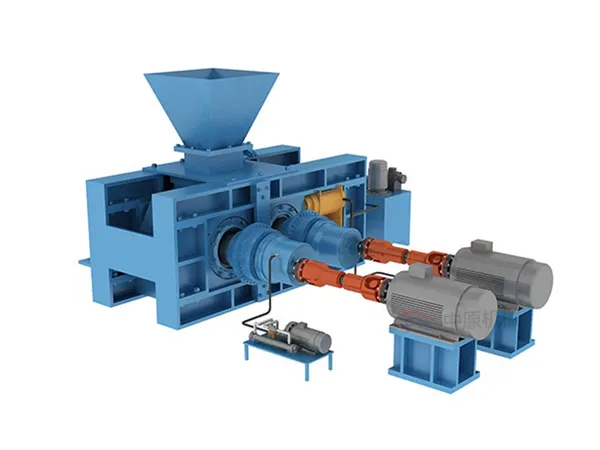

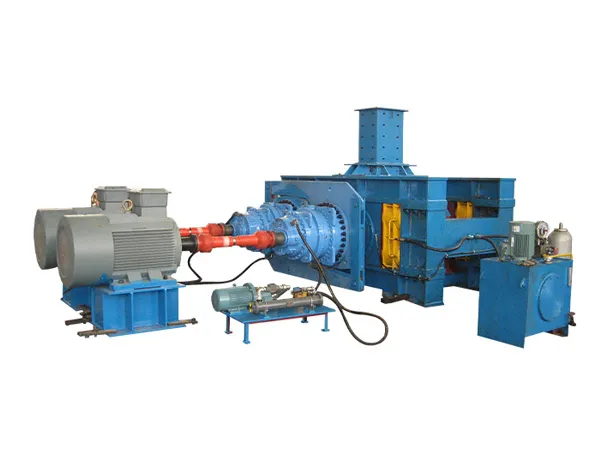

High-pressure grinding rolls (HPGR) are indispensable in modern mining and cement production, valued for their energy efficiency, high throughput, and ability to produce finely crushed, uniform material. However, as with any heavy-duty industrial equipment, HPGRs face inevitable wear and tear, which can compromise performance and increase maintenance costs. Extending the service life of these rolls is essential for maintaining consistent production and reducing operational expenses.

The durability of an HPGR largely depends on the quality of its rolls. Selecting wear-resistant steel or advanced composite materials can drastically reduce surface wear and deformation. Some manufacturers also offer rolls with specialized coatings or surface treatments that improve hardness and abrasion resistance, extending service life by up to 30% under high-load conditions.

Regular maintenance is key to detecting issues before they escalate. Inspect rolls frequently for cracks, surface wear, or uneven pressure distribution. Modern HPGRs can integrate real-time monitoring sensors for temperature, vibration, and load, allowing operators to plan maintenance proactively and minimize unexpected downtime.

Operating HPGRs within recommended pressure, speed, and feed rate ranges is critical for longevity. Overloading or running the machine at excessive speed accelerates wear, while maintaining optimal settings ensures efficient grinding with minimal stress on the equipment. Training operators on machinery limits further enhances long-term performance.

Lubrication is often underestimated but essential for reducing friction and preventing overheating. Using high-quality lubricants and adhering to regular lubrication schedules protects bearings and roll surfaces, reducing wear and enhancing overall reliability.

Even with excellent maintenance, rolls eventually wear out. Implementing a rotation schedule ensures even wear, and replacing severely worn rolls promptly prevents damage to other components while maintaining grinding efficiency.

Predictive maintenance solutions, such as AI-driven analytics and IoT monitoring, help operators anticipate potential failures and schedule interventions before problems occur. This proactive approach not only extends the lifespan of HPGRs but also reduces unplanned downtime and operational costs.

Maximizing the service life of high-pressure grinding rolls requires a balanced approach: using high-quality materials, performing regular maintenance, optimizing operational settings, and adopting advanced monitoring technologies. Mining and cement companies that implement these strategies can achieve higher efficiency, lower maintenance expenses, and consistent production output.

Add: Luoxin Industrial Zone,Luoyang City,Henan Province P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com

Official Agent of ZY MINING in Russia.

Please enter here.

Add: Luoxin Industrial Zone,Luoyang City,Henan Province P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com