-

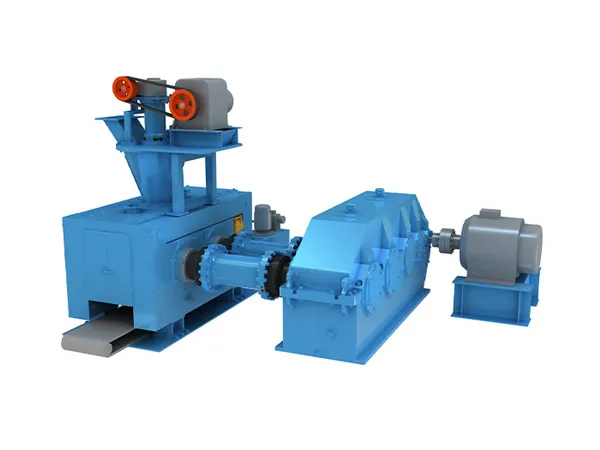

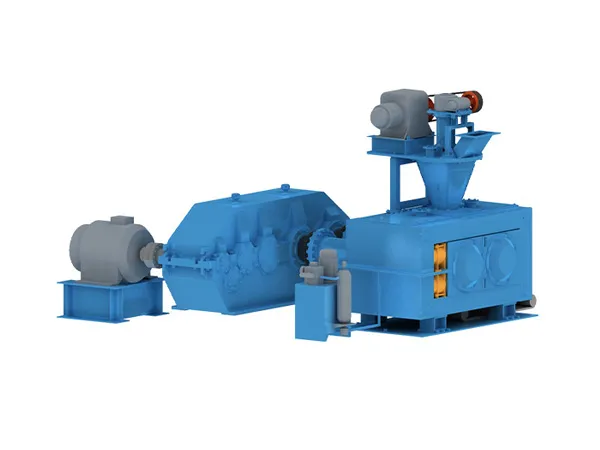

Products

-

Application

A briquetting machine is a valuable asset in industries ranging from biomass energy to metal recycling, playing a crucial role in turning raw materials into high-density briquettes. However, like any heavy-duty equipment, its performance and longevity largely depend on consistent and proper maintenance. Without routine care, issues such as wear and tear, material blockage, and mechanical failure can lead to costly downtime and reduced productivity.

Maintaining a briquetting machine for a long lifespan is crucial for maximizing efficiency, minimizing downtime, and ensuring consistent production.

Consistency is key. Develop and adhere to a detailed daily, weekly, monthly, and annual maintenance schedule.

Daily Maintenance:

Cleaning: Thoroughly clean dust, briquette debris, and other residue from the machine's surface, especially the feed port, molding die, and discharge port. Use compressed air for hard-to-reach areas.

Visual Inspection: Inspect all accessible seals for cracks or oil residue, and check connections where cylinders meet the barrel or piston. Look for any signs of dampness.

Component Connection Check: Before starting, verify the tightness of connecting bolts between the motor and the main machine, and the fixing bolts of the molding mold.

Monitor Operations: Pay attention to unusual sounds, vibrations, or changes in performance. Address any abnormalities immediately.

Warm-up: Allow the machine to warm up for 5-8 minutes in colder weather before pushing it to maximum output.

Weekly/Bi-Weekly Maintenance:

Lubrication: Regularly lubricate bearings, screws, and transmission chains according to the manufacturer's recommendations. Use the correct type and amount of lubricant.

Hydraulic System Check (for hydraulic machines): Monitor hydraulic pressure and temperature. Inspect hydraulic oil levels and condition, replacing it regularly. Check and replace hydraulic filters to remove impurities.

Monthly Maintenance:

Electrical System Check: Inspect wires for damage or aging. Clean dust inside the electrical control cabinet to prevent overheating of components.

Belt and Chain Tension: Check the tightness of belts and chains, adjusting them to the appropriate tension as per the instruction manual.

Quarterly/Bi-Annual/Annual Maintenance:

Main Mechanical Component Inspection: Inspect the wear of critical components like the screw (propeller/auger), molding die/mold, and pressure rollers.

Screw/Propeller: This is a key component. If severely worn, replace it promptly.

Molding Die/Mold: Check for wear, scratches, or depressions. Repair or replace if the molding size is inconsistent.

Pressure Roller: Inspect for wear, especially if processing abrasive materials.

Pressure System Calibration (if applicable): Calibrate the machine's pressure system using professional testing equipment to ensure accurate pressure for optimal briquette quality.

Temperature Sensor and Heating Element Check (if applicable): Verify the working status of these components to ensure temperature is controlled within the appropriate range.

Bearing Health Checks: Beyond lubrication, perform checks for wear and tear. Worn bearings can lead to noise, heat, increased energy consumption, and premature failure.

Oil Analysis: For hydraulic machines, analyze hydraulic oil every 250 operating hours to detect contaminants or degradation.

The quality and characteristics of your raw material significantly impact machine wear and briquette quality.

Moisture Content: Maintain the ideal moisture content for your specific material (e.g., 8-12% for wood chips/sawdust). Too dry material can increase friction and wear, while too wet material can cause blockages and affect briquette formation.

Material Cleaning: Remove impurities such as stones, metal particles, and sand from the raw material before briquetting. These can cause severe damage to pressing components. Consider installing magnetic or vibrating screens upstream.

Uniform Feeding: Ensure a consistent and uniform flow of material to avoid jams and strain on the hydraulic system.

Operator training and adherence to correct operating procedures are vital.

Avoid Overloading: Do not operate the machine consistently at maximum power or overload it, as this can lead to overheating and premature wear of the engine and hydraulics.

Gradual Start-up: If the machine has been inactive for a while, don't immediately run it at full capacity. Gradually increase the load.

Monitor Sounds and Vibrations: Train operators to recognize unusual sounds or vibrations, which often signal mechanical problems. Immediate investigation can prevent more severe damage.

Emergency Shutdown Procedures: Ensure all operators are thoroughly trained on emergency shutdown procedures.

Safety Precautions: Always wear appropriate protective gear (gloves, goggles) and never bypass safety interlocks.

How you treat the machine when it's not in use also impacts its lifespan.

Piston Protection (for hydraulic machines): When storing overnight or for extended periods, position pistons in a retracted state to relieve pressure on seals. Consider using reusable protective sleeves over cylinders.

Combat Cold: In freezing conditions, hydraulic oil can thicken. Consider tank heaters or switching to winter-grade fluids to reduce stress on seals during startup.

Humidity Control: If storing for more than 48 hours in a humid environment, run the machine for 10 minutes daily to circulate oil and displace moisture, preventing corrosion.

Disconnect Power: If the machine is not in use for an extended period, disconnect its electrical systems from the power supply.

Having common wearing parts readily available can significantly reduce downtime during breakdowns. These typically include:

Molding dies/molds

Pressure rollers

Bearings

Propellers/Augers (if applicable)

Seals

Heating elements (if applicable)

Maintenance Records: Keep detailed records of all maintenance activities, including dates, parts replaced, observations, and technician notes. This helps track wear patterns and predict future needs.

Operator Training: Regularly refresh and update operator training as new techniques or machine modifications are introduced.

Utilize Technology: Modern briquetting machines may have advanced sensors and monitoring software. Leverage these tools for real-time tracking of hydraulic pressure deviations, vibration analysis, and other performance metrics to enable predictive maintenance.

By diligently following these maintenance practices, you can significantly extend the lifespan of your briquetting machine, optimize its performance, and avoid costly unplanned downtime.

Official Agent of ZY MINING in Russia.

Please enter here.

Add: Luoxin Industrial Zone,Luoyang City,Henan Province P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com