-

Products

-

Application

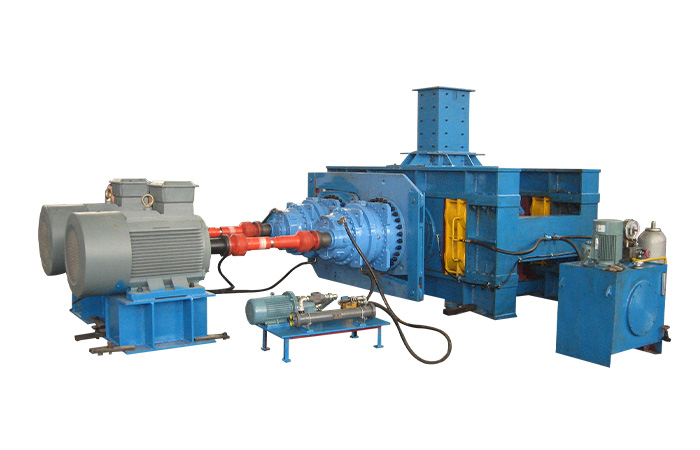

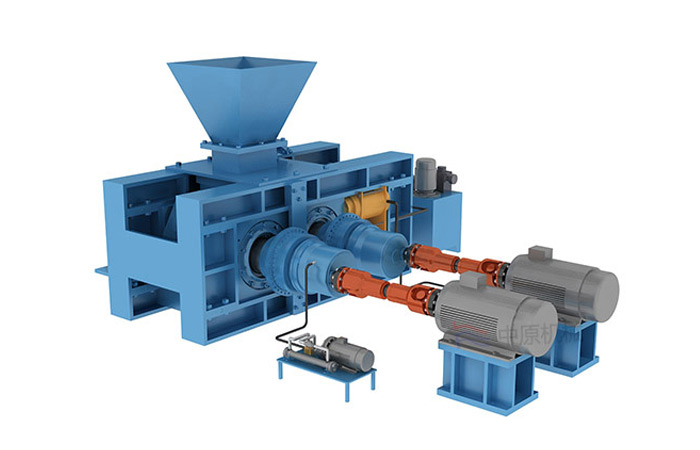

High pressure grinding rolls (HPGR) are a type of comminution equipment used in the mining and minerals processing industry. They are designed to reduce the size of particles by compressing and crushing them between two counter-rotating rolls with a small gap between them. HPGRs are typically used for processing hard and abrasive ores.

Feed Material Introduction: The ore or material to be processed is introduced into the gap between the two rolls. This feed material can vary widely in terms of size, hardness, and moisture content.

Comminution: As the rolls rotate, they exert high pressure on the feed material. This pressure causes the particles to break and deform, leading to the reduction in particle size. The material is primarily crushed through a combination of compression and interparticle breakage.

Particle Bed Formation: The crushed material forms a bed between the rolls. The particle bed acts as a cushion that helps to distribute the pressure more evenly and prevent excessive wear on the rolls.

Discharge: Once the material has been sufficiently comminuted, it exits the HPGR through the gap between the rolls. The product, often referred to as the "flakes," "chips," or "cakes," typically has a more uniform particle size distribution compared to traditional grinding methods.

Recirculation: In some cases, a portion of the product may be recirculated back to the HPGR for further grinding. This can help achieve the desired particle size distribution or improve overall efficiency.

HPGRs offer several advantages over traditional grinding methods, such as ball mills and SAG mills:

However, it's important to note that HPGRs also have limitations and challenges, such as increased sensitivity to variations in ore properties and potential issues with edge effects and particle weakening.

The operation of HPGRs requires careful process design and optimization to ensure efficient and effective comminution. Factors such as roll speed, feed material size and distribution, roll surface wear protection, and overall circuit configuration all play a role in determining the performance of an HPGR-based grinding circuit.

Add: Luoxin Industrial Zone,Luoyang City,Henan Province P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com

Official Agent of ZY MINING in Russia.

Please enter here.

Add: Luoxin Industrial Zone,Luoyang City,Henan Province P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com