-

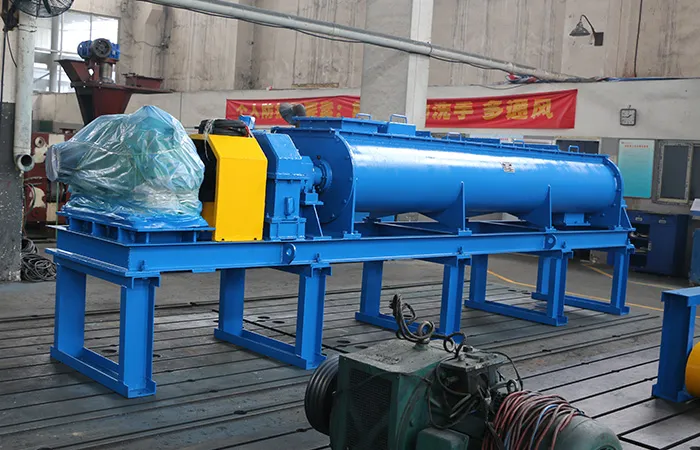

Products

-

Application

In industrial processing, achieving a consistent, high-quality blend of materials is crucial. The choice of mixer is a fundamental decision that impacts efficiency, product quality, and operational costs. Among the most common horizontal mixers are the single-shaft and double-shaft (or twin-shaft) designs.

While both are used for blending solids, sludges, and pastes, their internal mechanics create vastly different mixing environments. Choosing between a single shaft mixer and a double shaft mixer depends heavily on your specific mixing needs. Both types have distinct advantages and are suited for different applications.

Design: Features one rotating shaft equipped with mixing paddles or blades.

Mixing Action: Generally provides a gentler, more consistent mixing action. The paddles lift the material and allow it to fall, creating cross-mixing.

Ideal for:

Dry powders and granular materials: Think spices, flour, coffee beans, animal feed, fertilizers, etc.

Light pastes and some liquid applications: Where a homogenous blend without excessive shearing is desired.

Delicate blending: Materials that can be easily damaged or degraded by aggressive mixing.

Applications requiring low maintenance and operational costs: Simpler design generally means less to go wrong.

Key Features:

One central shaft with attached paddles or blades.

Uniform mixing for homogeneous products.

Lower initial investment and easier to maintain.

Can often mix down to a lower percentage of its rated capacity effectively.

Lower horizontal profile, which can be beneficial if height is a limitation.

Design: Features two horizontal shafts rotating in opposite directions. These shafts often have overlapping paddles or blades.

Mixing Action: Creates a counter-rotating motion that provides intensive, high-shear mixing. The two shafts and their intermeshing blades actively displace, shear, and distribute the material, resulting in faster and more thorough blending. It also creates a "fluidized bed" effect for optimal mixing.

Ideal for:

Heavy, wet, or high-viscosity materials: Such as concrete, mortar, slurries, sludges, sticky clays, and some highly filled compounds.

Applications requiring rapid and thorough blending: Where a high degree of homogeneity is crucial in a short time.

Processing materials with both wet and dry ingredients: Excellent for incorporating liquids into powders to create a consistent mixture.

Industries like: Construction (concrete batching plants), chemical processing, heavy industries, wastewater treatment.

Key Features:

Two synchronized, counter-rotating shafts.

Superior mixing efficiency for tough, sticky, or high-density materials.

Faster mixing time and more consistent results (often higher mixing evenness, e.g., CV≤5%).

Often has a more flexible and sizeable discharge port.

Can handle a wider range of viscosities and densities.

Can incorporate additional components like high-speed dispersers for more vigorous mixing.

Material Type and Characteristics:

Dry, free-flowing powders, granules, or delicate materials: Single shaft is likely sufficient.

Heavy, sticky, wet, high-viscosity, or cohesive materials (e.g., concrete, sludge): Double shaft is generally preferred for its intensive mixing action.

Presence of liquids/binders: Double shaft excels at incorporating liquids uniformly into dry materials.

Desired Mixing Homogeneity and Speed:

Gentle, consistent, but not necessarily ultra-fast mixing: Single shaft.

High homogeneity and rapid mixing time (short cycle times): Double shaft is superior.

Production Volume and Batch Size:

Both types come in various capacities, but double shaft mixers are often chosen for larger-scale industrial operations where high throughput is critical.

Maintenance and Operational Costs:

Lower initial investment and easier maintenance: Single shaft.

Higher initial investment and potentially more complex maintenance: Double shaft (due to two shafts and more robust design).

Shear Requirements:

Low shear, gentle blending: Single shaft.

High shear, intensive mixing, breaking up lumps/agglomerates: Double shaft.

Discharge Performance:

Double shaft mixers often have more flexible and efficient discharge ports, especially for challenging materials.

Noise Level:

Double shaft mixers can sometimes produce minimal noise during operation due to their driving system (e.g., sliding gear structure with V-type belt).

In Summary:

Choose a Single Shaft Mixer if: You primarily deal with dry powders, granules, light pastes, or delicate materials, and require consistent, homogeneous blending with lower initial costs and easier maintenance.

Choose a Double Shaft Mixer if: You need intensive, high-shear mixing for heavy, wet, sticky, or high-viscosity materials, require rapid processing, and a very high degree of homogeneity, especially when incorporating liquids into solids.

It's always recommended to consult with mixer manufacturers or suppliers who can offer expert advice based on your specific application and material properties. Some even offer test facilities to determine the most suitable mixer for your needs.

Add: Luoxin Industrial Zone,Luoyang City,Henan Province P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com

Official Agent of ZY MINING in Russia.

Please enter here.

Add: Luoxin Industrial Zone,Luoyang City,Henan Province P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com