-

Products

-

Application

The conveyor is mainly used for the transportation of materials. It has the point that the direction is changeable and the conveying direction can be flexibly changed. We commonly have screw conveyors and belt conveyors, etc. Among them, belt conveyors are the main way of conveying bulk materials. When we use or maintain the machine improperly, the conveyor may fail and cause downtime. Do you know the reason for the downtime of the conveyor?

The screw conveyor has the advantages of small cross-sectional size of the whole machine, good sealing performance, multi-point loading and unloading in the middle, and easy operation and maintenance. It is suitable for conveying powdery, granular and small block materials. It is widely used in building materials, metallurgy, Chemical, electric power, coal, machinery, grain, food and other industries; it is not suitable to transport materials that are perishable, viscous, and easy to agglomerate.

1. The material is too large

Problem: The material to be conveyed is too large, the material cannot pass through the middle hanging bearing smoothly, and the material resistance at the middle bearing is too large, causing the screw conveyor to stop suddenly.

Solution: judge the size of the material before conveying to avoid the material being too large and stuck in the middle of the hanging bearing, resulting in downtime.

2. Material blockage

Problem: Blockage of material in the screw conveyor can also cause the motor to be overloaded and shut down.

Solution: We must clean up the material in the screw conveyor, keep the conveyor unobstructed, and install a belt cleaner to avoid blockage due to excessive viscosity of the material.

3. Seal damage

Problem: The resistance at the intermediate bearing is too large and the seal is damaged. Material entering the bearing causes the bearing not to rotate or the bearing is damaged.

Solution: The seal needs to be replaced, and the abnormality at the intermediate bearing should be checked for repair.

4. Bearing burnt

Problem: The reducer bearing is burnt, resulting in downtime.

Solution: Replace the new parts to ensure the normal operation of the machine.

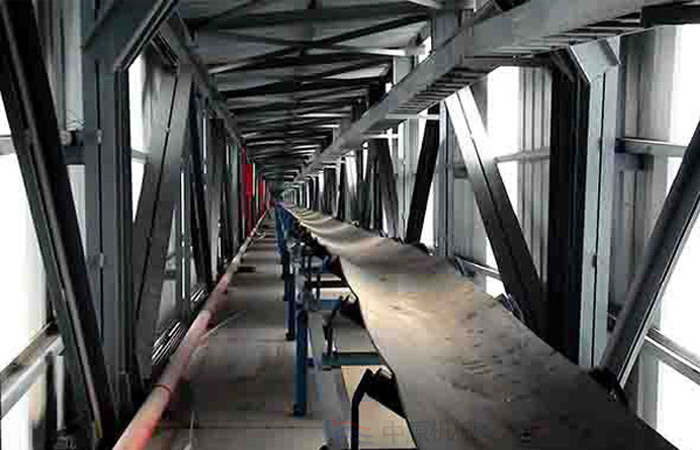

The belt conveyor has the advantages of strong conveying capacity, long conveying distance, stable and reliable operation, high efficiency, low noise, simple structure and easy maintenance, and can easily implement programmed control and automatic operation. It is suitable for transporting bulk or finished goods in metallurgy, mining, coal, chemical, electric power, building materials and other industries.

1. Belt deviation

Problem: Belt misalignment occurs when the belt deviates from its desired path. This is a serious problem that can lead to belt damage, equipment failure and material spillage. There are many reasons for belt deviation, such as insufficient belt tension, eccentric load, incorrect splicing, component deflection, material accumulation on components and components, and so on.

Solution: A better solution is to find the root cause of belt misalignment to prevent the same problem in the future. Carrying out a belt inspection can help identify any potential problems causing belt misalignment so that an appropriate solution can be developed based on the problem. If the belt is only slightly misaligned, the self-aligning idler can be used to correct the belt's trajectory and ensure that the belt will always run straight in the future.

2. Material return

Problem: When a small amount of material sticks to the belt, the conveyor will carry back the phenomenon. This can cause material to build up under the conveyor belt, or on idlers and drums. Certain materials, such as clay and certain ores, stick to the belt more easily than others. Although the return volume is very small, over a long period of time, there will be tons of materials accumulated, which has to be cleaned twice. Material carry-back can also create safety and environmental hazards, increase cleanup costs, and generally prevent conveyor systems from operating in good condition.

Solution: A simple solution is to install belt cleaners to prevent carryback. The benefits of a belt cleaner more than offset its upfront investment cost. Reduced material spillage saves maintenance costs and creates a safer work environment. In addition, clean belts prevent premature idler failure, extend belt life, and keep the system in good operating condition.

3. Belt damage

Problem: Belt damage can be caused by several factors, such as excessive impact force, misalignment, improper use of sealing systems or belt cleaners, seizing components and insufficient pulley traction. Belts are expensive parts of conveyors, so the underlying cause of belt problems must be identified and action taken to avoid irreparable damage.

Solutions: There are many causes of belt damage and therefore many different solutions. For example, installing buffer rollers or brackets in the feeding area can disperse the impact of falling material, thereby reducing wear and tear on the belt. With a proper sealing system, the belt can be prevented from being damaged by stuck material. With the proper roller wrap material, you can increase the friction and prevent the belt from slipping without damaging it quickly. These solutions all help to minimise maintenance downtime and are usually determined by a secondary belt inspection. Belt inspections can catch minor belt damage, preventing major failures in the future.

Through the above explanations, I believe that you also have some understanding of the reasons for the downtime of common conveyors. You can also understand if similar problems occur in the future. In addition, we should take precautions before they happen, maintain regular maintenance during use, and judge the size of materials in advance. whether it can pass.

Add: Luoxin Industrial Zone,Luoyang City,Henan Province P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com

Official Agent of ZY MINING in Russia.

Please enter here.

Add: Luoxin Industrial Zone,Luoyang City,Henan Province P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com