-

Products

-

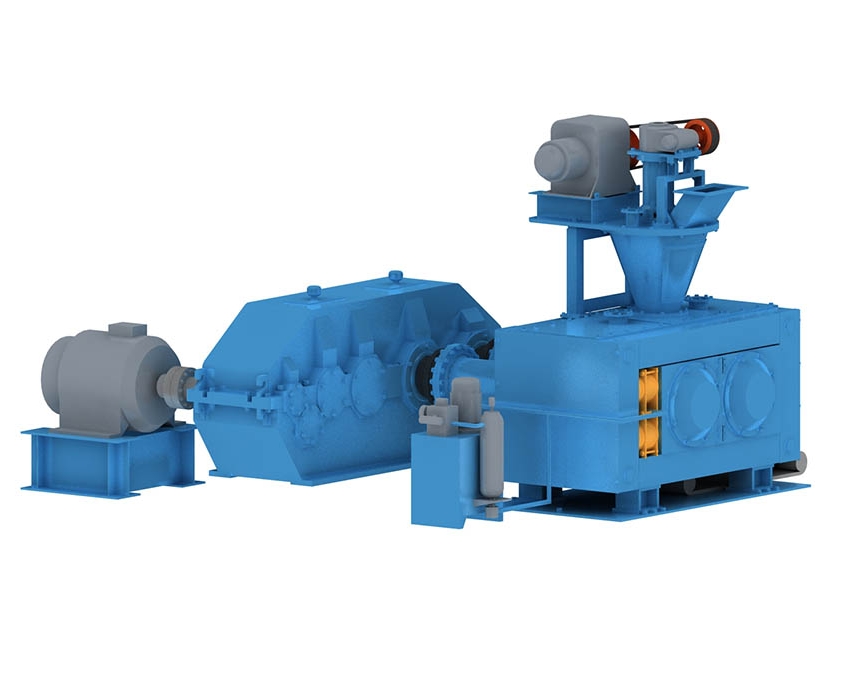

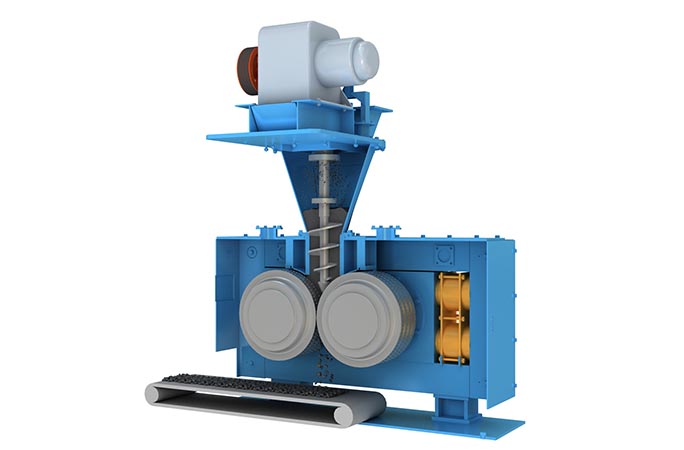

Application

The briquetting machine is in a state of continuous operation for a long time, coupled with poor maintenance and other internal and external factors, causing many parts to fail prematurely. The service life of the briquetting machine mainly depends on the quality of its wearing parts, especially the pressure roller. A good pair of pressure rollers will greatly improve the service life of the ball press, but even the best rollers will be scrapped. Time limit and standard, then what should be the standard for scrapping the wearing parts of briquetting machine?

1. The distortion of the gear ring rim should not be greater than 7.5mm.

2. The wear of the pinion surface should not be greater than 30% of the tooth thickness. The wear of the large tooth surface should be greater than 25% of the tooth thickness. It can be used on the reverse side, and it should be scrapped when it is ground to 1/2.

3. Grooves, marks on the outer surface of the hollow shaft or local wear on the inner circular surface will cause the hollow shaft to deform and crack, and should be replaced.

The above situations are common to us. If the briquetting machine is damaged, it can be used normally. Not only should it be carefully maintained, but also used in principle. Usually the machinery is broken, we will ask a repairer to repair it. In fact, we can also repair some things ourselves, and then we can use it.

In our daily use of dry powder ball presses, there are usually some undesirable phenomena. Sometimes users do not have experience in this area and have paid enough attention to this, but the arbitrary development of some phenomena will cause very serious consequences.

More common phenomena:

1. The appearance of the hollow shaft is caused by grooves, marks or partial wear on the inner circular surface to cause deformation of the hollow shaft and cracks and other conditions should be replaced.

2. The distortion of the gear ring rim should not be greater than 7.5mm.

3. The wear of the pinion surface should not be greater than 30% of the tooth thickness. The wear of the large tooth surface should be greater than 25% of the tooth thickness. It can be used on the reverse side, and it should be scrapped when it is ground to 1/2.

4. The wear of the bearing bush is greater than 1/3 of its thickness.

The above is the standard standard of the wear and scrap parts of the briquetting machine in use. If there are any of the above problems, the briquetting machine parts should be replaced in real time. Abandoned briquetting machine accessories, at the same time, they must be regularly adjusted to make the briquetting machine longer life.

Official Agent of ZY MINING in Russia.

Please enter here.

Add: Luoxin Industrial Zone,Luoyang City,Henan Province P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com