-

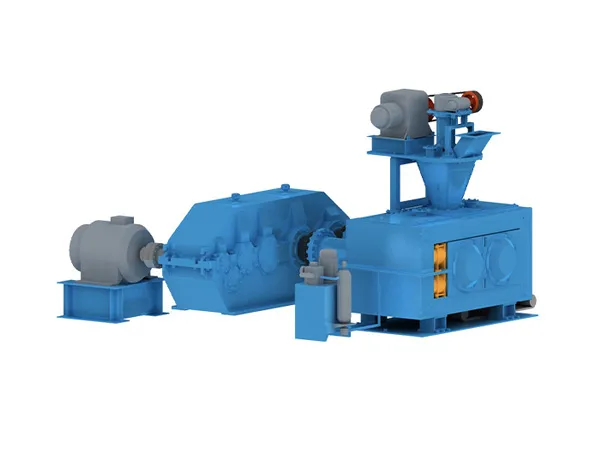

Products

-

Application

Choosing the right ball press machine is a critical step in setting up an efficient and profitable briquette production line. Whether you're working with coal powder, metal fines, charcoal dust, or mineral residues, selecting a machine that fits your raw materials, production capacity, and budget will directly impact the quality and strength of your briquettes. In this guide, we’ll walk you through the key factors to consider when buying a ball press machine.

The type of raw material you'll be briquetting is paramount. Different machines are designed for specific materials and their characteristics (moisture content, particle size, binding properties).

Common Materials:

Biomass: Sawdust, wood chips, agricultural residues (straw, rice husks, bagasse, coffee husks, peanut shells), bamboo.

Coal/Charcoal: Coal powder, charcoal dust, coke dust, lignite, anthracite.

Minerals/Ores: Iron powder, mineral powder, oxidized scale, slag, gypsum, tailings, sludge, kaolin, activated carbon, metal fines.

Others: Quicklime powder, magnesium powder, refractory materials, ceramic materials.

Considerations:

Particle Size: Most ball press machines require the raw material to be finely ground (often less than 3mm, with a significant percentage below 1mm) for optimal briquette formation and strength. You may need a grinder or hammer mill as a pre-processing step.

Moisture Content: The ideal moisture content varies by material and machine, but it's often around 8-10% for charcoal/coal and can be higher for some biomass.

Too much or too little moisture can significantly impact briquette quality.

Determine your desired output. This will dictate the size and power of the machine you need.

Factors:

Amount of raw material available.

Required briquette output per hour/day (e.g., 1-2.5 t/h, 3-5 t/h, 5-8 t/h, up to 28 t/h for larger models).

Operating hours (single shift, continuous operation).

Calculation: For a basic estimation, consider the density of your briquettes and the volume they occupy, then factor in the machine's efficiency and the time available for production.

Ball press machines typically produce briquettes in various shapes, including:

Ball (spherical)

Pillow

Oval/Ovoid

Egg

Square

Customized shapes

Specialized shapes: Honeycomb (for coal), cylinder with a hole (for BBQ charcoal or shisha charcoal).

Roller Design: The shape and size of the briquette are determined by the design of the press rollers. Ensure the roller pit size is appropriate for your material and desired briquette properties (e.g., flat square for dry powder, large spherical for charcoal/coal).

The required pressure depends on the material and the desired briquette density and strength.

Pressure Range: Machines can offer pressure ranges from 10,000 to 30,000 PSI.

Roller Shell Material: The material of the press rollers is critical for durability and wear resistance. Common materials include:

65 Manganese (65Mn): Popular and cheaper, suitable for small-scale production, requires carburizing and heat treatment.

9 Chromium 2 Molybdenum (9Cr2Mo) / High Chromium Alloy: Forged parts, used in medium to large briquette presses with high output, capable of pressing tougher materials like mineral powders.

Wear and Tear: Rollers are the most vulnerable parts. Consider the material, design, and ease of replacement.

For most materials, a binder is necessary to hold the briquettes together, especially in ball press machines.

Purpose of Binders: Improve durability, control burn rate, enhance water resistance, and reduce dust.

Types of Binders:

Starch (corn, wheat, cassava, potato): Common for BBQ charcoal and biomass briquettes. Requires gelatinization (cooking with water). Clean burning.

Molasses + Lime: Inexpensive, strong bonding, moderately water-resistant. Used for coal, charcoal, and steel dust.

Cement: Strong and durable for mineral briquettes, but adds ash and reduces calorific value for fuel briquettes.

Sodium Silicate: Excellent durability, fast curing, good for waterproofing industrial briquettes.

Clay/Kaolin: Readily available and cheap, but high ash content and weaker mechanical strength.

Gum Arabic: Natural, strong binder for specialty fuels, but expensive.

Wood Tar/Pitch: Can be used, but requires re-carbonization to avoid heavy smoke.

Cow Dung/Paper Pulp: Can be used as binding materials.

Binderless Briquetting: Some high-pressure machines can achieve binderless briquetting, especially with materials containing natural lignin (e.g., certain biomass).

This is often achieved by releasing natural binders within the material through high pressure and sometimes heat.

Considerations:

Cost and Availability: Choose a binder that is readily available and economical for your operations.

Briquette Quality: The binder affects the final briquette's strength, burn characteristics, ash content, and water resistance.

Mixing System: Ensure the machine or the overall production line includes an effective mixing system for homogeneous binder distribution.

Briquette machines can be powered by electricity, hydraulics, or even manual labor for small-scale operations.

Electric: Most common for factory settings, efficient.

Hydraulic: Ideal for locations with limited electricity, can use diesel engines.

Manual: Suitable for very small-scale or off-grid use.

Energy Consumption: Look for machines with high energy efficiency to minimize operating costs.

Decide on the level of automation you need.

Manual: Requires more labor.

Automatic: Automated features for feeding, pressing, and discharge, leading to higher efficiency and consistency, but generally more expensive.

Control Systems: Advanced systems can monitor and adjust parameters like pressure, temperature, and density.

Consider the long-term operational aspects.

Material Quality: Look for machines built with high-quality, durable materials and components to ensure reliability and minimal downtime.

Spare Parts: Check the availability and cost of spare parts, especially for wear-and-tear components like rollers.

Cooling System: Ball presses can generate significant heat. Consider whether an air-cooled or water-cooled system is more suitable for your needs and maintenance capabilities. Water-cooled systems are more complex but can offer better heat dissipation.

Manufacturer Reputation and After-Sales Service: A reputable manufacturer will offer good customer support, technical assistance, and training.

Initial Investment: Balance the cost with the machine's quality and features. Premium machines may offer better quality and efficiency but come at a higher price.

Operating Costs: Factor in electricity consumption, maintenance, and consumables (binders).

Space: Ensure you have adequate space for the machine and its associated equipment (feeders, conveyors, dryers, etc.).

By carefully considering these factors, you can select a ball press machine that is well-suited to your specific briquetting needs and contributes to a successful and profitable operation.

Add: Luoxin Industrial Zone,Luoyang City,Henan Province P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com

Official Agent of ZY MINING in Russia.

Please enter here.

Add: Luoxin Industrial Zone,Luoyang City,Henan Province P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com